Waterite Excelight EL08NSFAK User manual

NSF 55A CERTIFIED RESIDENTIAL ULTRAVIOLET

WATER DISINFECTION SYSTEM

OWNER’S MANUAL

For Excelight Ultraviolet system model

EL08NSFAK

IMPORTANT!

READ AND UNDERSTAND THE TERMS OF THE

MANUFACTURER’S WARRANTY ON PAGE 14 OF

THIS MANUAL. FILL OUT THE WARRANTY

REGISTRATION CARD WITH THE CSA NUMBER

FOUND ON THE BALLAST

R1

©Copyright 2020 by Waterite, Inc.

1

Congratulations!

Your new Excelight UV disinfection system is made from the highest quality

components available and is designed to provide many years of reliable

service. Please take the time to read this manual completely so that you may

provide the correct installation and maintenance, ensuring optimal system

safety, performance and life.

REGISTER YOUR PRODUCT ONLINE AT WATERITE.COM OR FILL OUT

THE INCLUDED PRE-PAID, SELF ADDRESSED POSTCARD.

WARNING!

WHERE MICROBIOLOGICALLY ACTIVE WATER IS KNOWN TO EXIST, IT IS

HIGHLY RECOMMENDED THAT AT LEAST ONE ADDITIONAL

DISINFECTION BARRIER SUCH AS CHLORINATION OR ABSOLUTE

FILTRATION IS USED TO TREAT DRINKING WATER, IN ADDITION TO UV

TREATMENT. CAREFULLY MAINTAIN ALL WATER TREATMENT

EQUIPMENT AND HAVE DRINKING WATER TESTED REGULARLY.

UV RADIATION HAZARD

NEVER OPERATE A UV LAMP OUTSIDE THE DISINFECTION CHAMBER.

EXPOSURE TO UV LIGHT CAN RESULT IN SERIOUS INJURY AND

EXTREME BURNING OF THE SKIN AND EYES

Excelight UV disinfection systems are equipped with a visual lamp failure

alarm. For your safety, it is necessary that you determine that the visual

alarm can be seen easily where you install the unit.

In order to optimize the disinfection performance, you must only use the unit

with water that meets or exceeds the minimum standard and replace the UV

lamp at recommended intervals (9000hrs). Failure to follow these guidelines

will result in reduced disinfection performance.

Excelight NX UV systems can be ordered with an optional solenoid valve.

This valve when activated will shut off the flow of water when an alarm

condition is present, or if the UV power source loses power for any reason,

preventing you from using any untreated water.

2

SAFETY INSTRUCTIONS

Danger - To reduce the risk of electrical shock, this system must be grounded.

Connect your UV system to a grounded, GFI protected (3 pronged) receptacle

(120vac 60hz) and ensure that the lamp connector ground wire is securely

attached to the grounding lug on the UV chamber.

Do not plug in unit if any of the external surfaces or electrical components are wet.

It is normal for there to be some condensation on the stainless-steel chamber in

high humidity climates.

To avoid possible electric shock, special care should be taken since water may be

present near electrical equipment. Unless referred to in these instructions, do not

attempt repairs to the unit yourself. Contact the manufacturer for service advice.

Do not operate this system if it has a damaged electrical cord, if the plug-end is

malfunctioning, or the unit has been dropped or damaged in any way.

Do not use this unit for anything other than its intended potable water application.

The use of attachments not recommended, approved, or sold by the

manufacturer/distributor may result in an unsafe condition.

Before doing any cleaning or maintenance, always unplug the electrical ballast and

isolate and drain the chamber.

Protect your unit from freezing. Drain all water from unit if freezing temperatures

exist.

RAW WATER QUALITY

It is strongly recommended that you have your raw water professionally tested for

dissolved mineral content, turbidity and microbiological activity. Your UV

disinfection system requires clean, clear water for optimum performance. You

should only operate your unit if the source water meets the following minimum

standards:

Turbidity <1 NTU

Suspended Solids <10mg/L

Colour None

Total Iron <0.3mg/L

Manganese <0.05 mg/L

Hardness <7 gpg

UVT% >80%

Where raw water conditions do not meet these minimum standards, pre-treatment

equipment such as an inline or automatic filter(s), ion exchange softener or an RO

system must be installed. Consult with your local water treatment specialist for

advice.

3

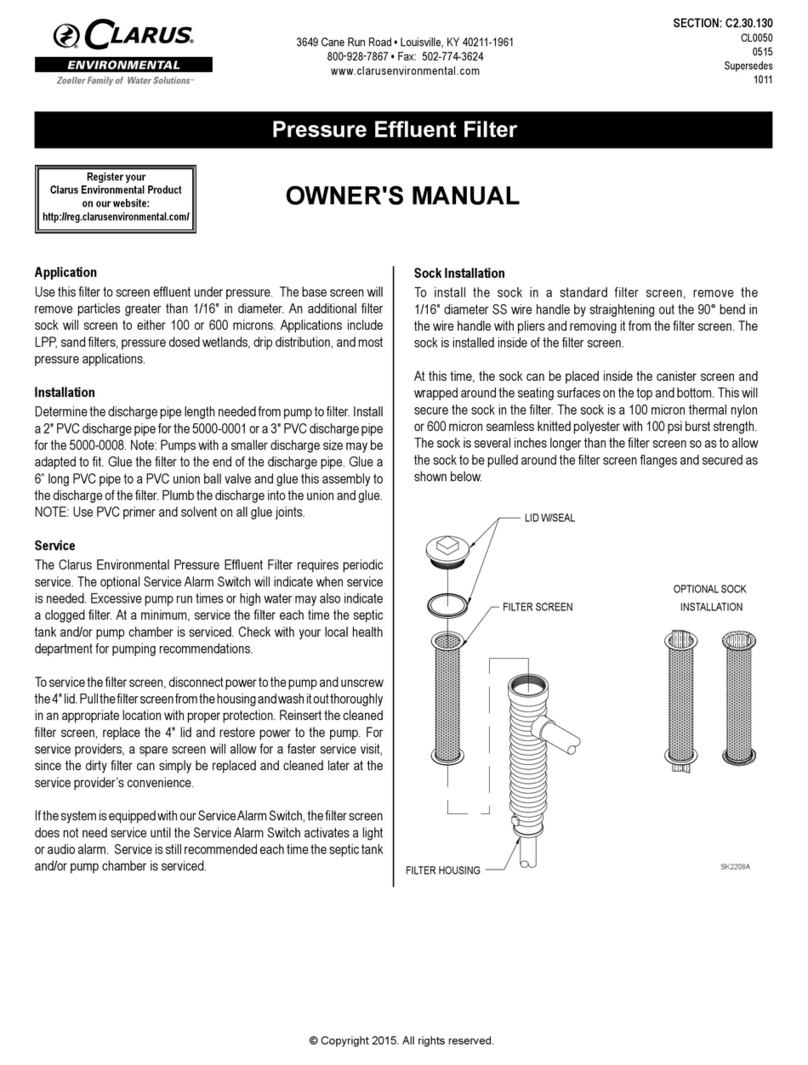

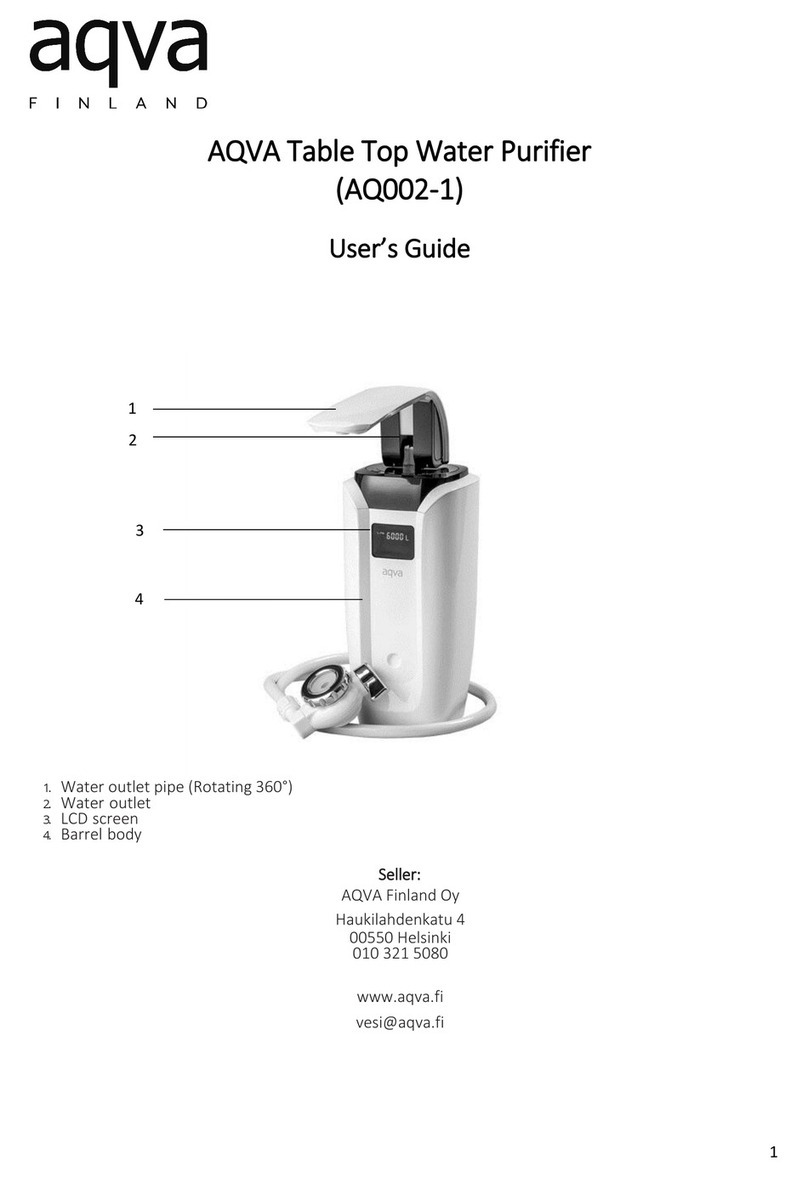

SYSTEM COMPOMENTS

Electrical Sleeve Mounting Chamber Thermal Sleeve

Cap O rings Bracket (2) Control Valve Cap

Power Flow

Cord Restrictor

Transmittance Ballast Quartz Ultraviolet Thermal Control

Sensor 120vac Sleeve Lamp Valve Adapter

BALLAST AND DISPLAYS

Function display mj/cm2Reset Transmittance

indication Button Monitor Port

(2 pin)

On/Off

Optional

Solenoid Port

120 Vac 60 hz (3 pin)

Receptacle

Lamp pin Electrical Chamber Lamp

Connector Sealing Cap Ground Wire Harness

4

Where microbiological activity is indicated to be present in your water

source, it is highly recommended that additional disinfection barriers be

used in addition to your UV system. This could include water well

chlorination using a pellet dispenser, inline chlorine injection using a dosing

pump and a contact tank, <1-micron absolute filtration or ozone injection.

The use of multiple barriers will assure safe drinking water in the event of

the failure of any one of the disinfection methods.

INSTALLATION CAUTIONS

Connect your UV lamp to a grounded (3-pronged)

receptacle (120V/60Hz) (a GFI and power surge

protector is highly recommended) and ensure that

the lamp connector ground wire is connected to the

grounding stud on the end of the reactor vessel.

Grounding Lug

1. Excelight UV disinfection devices are designed to be installed on the cold-water

line only.

2. Install the Excelight UV disinfection system indoors in a protected area where

the temperature does not fall below 4°C (40°F) and the humidity level is low (to

prevent condensation on the chamber). This unit functions optimally between

9-29°C (49-85°F)

3. Use Teflon tape on all plumbing connections. Do not use other sealants.

4. If a pump is used in the water filtration system where the UV disinfection system

is installed, the UV disinfection system should not connect to the same AC

supply circuit as the pump. The voltage drop caused by the pump starting may

trigger an abnormal operating condition alarm on the UV ballast.

INSTALLATION PROCEDURE

In most installations, your UV disinfection system should be the last component in

your water treatment system, downstream from all other equipment. Choose a

location for installation with easy access to a 120VAC electrical outlet. This UV

system must be installed vertically with the inlet port positioned below the outlet

port.

A minimum distance of 17” (438mm) clearance is necessary to remove the

UV lamp from the reactor. If this is not practical the reactor can be removed

from the mounting clips for maintenance. Use of unions on the inlet and

outlet will facilitate this removal.

5

1. Shut off the main water supply valve.

2. Mount the unit to the wall in the selected location using the brackets and screws

provided. (Fig. 1)

3. Mount the power supply beside or above the reactor vessel to assure that any

leaks cannot migrate to the power source. Never mount the power supply

below the reactor chamber. (Fig 2) DO NOT PLUG IN AT THIS TIME.

4. NOTE: Wrap all threaded plumbing connections with Teflon tape prior to

assembly. Do not use Teflon tape on the chamber end caps.

5. The unit must be installed vertically with the inlet and outlet ports accessible.

The lamp connection must be at the highest point. (End with ground terminal)

This will assure that any dripping condensation or possible leaks will not migrate

to the lamp harness or electrical connections. The water inlet port must be the

lowest port. This allows air to escape the housing, and ensures proper flow

past the UV lamp and sensor. (Fig. 2)

6. Install the flow restrictor to the inlet port (lower port). The arrow on the restrictor

indicates the direction of the water flow. (Fig. 3 & 4) The arrow should be

pointing towards the chamber.

7. Screw the brass thermal relief valve into the SST adaptor, ensuring the O-ring

is attached to the brass valve as shown in fig 5A. Hand tighten + ¼ turn with a

wrench. Now install the SST thermal relief valve adaptor to the outlet port (upper

port) Fig. 6. Attach the 3/8” flexible tube to the barbed fitting on the valve and

run the tube to the drain.

8. Connect new plumbing to the flow restrictor (lower) and the thermal adapter

(upper). Make sure to install shutoff valves and unions before and after the unit

for servicing. Note: If installing a pre-filter, use a 5-micron filter and ensure the

direction of water flow through the filter housing is correct.

9. If a solenoid valve is going to be used, the valve can be mounted directly to the

inlet port feed line. Keep a minimum of 12” (30cm) distance from the thermal

valve if the solenoid valve has to be installed on the output port.

6

WARNING:

If soldering copper pipes, do not allow heat near plastic or nylon threads

or fittings.

10.Remove the chamber end caps. Note that the quartz sleeve has not been

factory installed. Remove it from its packaging. Use a soft non-abrasive cloth

to handle the sleeve. Wipe off any debris or fingerprints prior to installing.

Slide the quartz sleeve into the chamber until about 1/2” (1.25 cm) protrudes

from the either end. Slide one of the black supplied O-rings over the lower end.

Next, slide one of the white gasket rings on the sleeve (Fig. 8 bottom) Screw

on the bottom end cap (Fig. 9). Do not tighten. Install the other black O-ring and

white gasket ring over the open end of the sleeve on the chamber end that has

the grounding screw attached. (Fig. 8 Top) Screw on the electrical end cap.

(Fig. 10) Turning in opposite directions, hand-tighten both end caps at the same

time. Once assembled, tighten each cap ¼ turn using a wrench or pliers, do not

over-tighten.

11.Remove the lamp from its protective packaging. Clean lamp exterior with a

clean non-abrasive cloth. Be careful not to leave fingerprints on the lamp.

Connect the 4-pin electrical connector to the pins on the UV lamp. (Fig. 11)

Insert the lamp through the opening at the end of the electrical end cap until the

electrical connection is inside the end cap.

12.Loosen the set-screw on the side of the lamp plug cover, and place the cover

over the ledge of the electrical end cap. Tighten the set-screw. (Fig. 12)

13.Remove the nut on the grounding stud and place the grounding wire (green &

yellow) onto the stud. Replace the nut and tighten. (Fig 13)

14.Remove the transmittance sensor from its packaging. Ensure the O-ring is in

place above the threads on the sensor end. Wipe the face of the sensor with a

clean non-abrasive cloth to remove any debris or fingerprints. Screw the sensor

into the middle port. Hand-tighten + ¼ turn using a wrench (Fig. 14)

15.Connect the electrical end of the sensor to the right-hand side 2 pin terminal on

the ballast chassis. (Fig. 15)

16.If the Optional solenoid is installed on the unit, connect the 3-pin electrical

connector supplied with the solenoid, to the 3-pin adapter on the right-side

middle of the UV ballast. (Fig. 15)

17.Ensure the valves on either side of the UV disinfection unit are closed. Open

the main water supply valve. Open the valve on the discharge side of the

disinfection unit. Slowly open the feed side valve (lower) on the disinfection unit.

Check for leaks. If any leaks are present, close valves and repair.

18.Connect the UV power source to a 120v receptacle. Turn on the power switch

on the side of the ballast. Wait for 5-10 seconds before the Lamp On will be

indicated. It will take additional time before the green LED indicates the lamp is

ignited with over a 40mj/cm2UV intensity, and if installed, the solenoid will open

only after the UV cm2exceeds 40mj/cm2. The current mj/cm2dosage, the Lamp

7

ON/Lamp Fault and the cumulative operation hours will be displayed on the

screen.

19.Before service begins all household, plumbing lines should be

disinfected. (See PLUMBING DISINFECTION PROCEDURE BELOW).

20.Your Excelight NX UV Disinfection System is now ready for use.

PLUMBING SYSTEM DISINFECTION PROCEDURE

THE FOLLOWING DISINFECTION PROCEDURE IS GENERALLY ACCEPTED

AS BEING SUITABLE FOR THE DISINFECTION OF PLUMBING SYSTEMS

KNOWN TO BE CONTAMINATED.

IF YOU ARE UNCERTAIN ABOUT THE EFFECTIVENESS OF THIS

PROCEDURE YOU ARE ADVISED TO CONTACT YOUR LOCAL HEALTH

AUTHORITY RESPONSIBLE FOR WATER SAFETY.

During the UV disinfection process the only place disinfection takes place is within

the reactor chamber. There is no residual disinfectant capacity. Therefore, it is

necessary to chemically disinfect the plumbing system prior to the initialization of

the UV system.

1. Turn the UV system shut off valves to the closed position.

2. The disinfection of the plumbing system is most readily accomplished by

removing the 5-micron pre-filter cartridge and adding 250-500ml (1-2 cups) of a

standard 5% concentration of unscented household bleach into the empty filter

housing and re-attaching.

3. Verify that the UV system is connected to the AC power voltage and operating

properly.

8

4. Turn the valves to the open position and let the water flow.

5. Open all faucets, fixtures and appliances in turn until you can easily smell

chlorine. This includes outside faucets, laundry machines, showerheads and

any device or appliance attached to the plumbing system. Close the fixtures and

let the system sit for 4 hours. Do not use or consume system water during

this process.

6. Close the valves on the UV system. Re-install the pre-filter. Open the valves

and flush all fixtures and lines thoroughly.

The introduction of a chlorine disinfectant to a hot water heater that has been

used with untreated water or water with excessive amounts of iron,

manganese or other organic materials may lead to the oxidation of these

particulates. If you feel that these conditions may apply to your installation,

a thorough flushing of the hot water tank after the disinfection should be

undertaken to eliminate the oxidized material from the system. Consider

replacing an aged hot water tank at this time.

UV POWER SOURCE (BALLAST)

The microprocessor controlled power source supplied with your Excelight NX

System has a visual alarm to indicate lamp operation/failure and a cumulative

system operation timer. The unit is available with an optional shutoff solenoid

which will activate when there is an alarm, turning off the water until the alarm is

corrected.

The LCD display shows the actual current UV dosage (AV: XX.X mj/cm2), the

cumulative operation hours (AT: XXXX) of the lamp, and Lamp status (Lamp On

or Lamp Fault).

If the actual UV intensity falls under 40mj/cm2, the unit goes into the low UV alarm

mode, a red will flash on the controller and the optional solenoid valve, if installed,

will close.

UV Power Source Initialization Sequence

1. Plug in the UV power source

2. Press the on/off button

3. The unit will turn on and the display will light.

a. Initially the display will read Lamp Fault.

b. After 3-5 seconds, this will change to Lamp ON. Additionally, the UV

dosage will start to climb and as it does the intensity LED indicator

lights will change from Red - Yellow - Green

c. The Red LED indicates the UV output is less than mj/cm2a Yellow

LED indicates the UV dosage is ranged from 40 to 50 mj/cm2, and a

Green LED indicates the UV dosage is greater than 50mj/cm2.

d. If a solenoid valve is connected to the UV power source, it will open

when the UV level reaches 40mj/cm2.

Normal Operation:

During normal operation, the Green LED is illuminated. If the unit sits for a long

period of time it is normal for the Yellow LED to illuminate as the water temperature

9

rises in the UV chamber. This should change back to Green when water is being

used.

Lamp Failure:

When the UV power source detects a lamp failure or enters the auto shut down

mode due to abnormal operating conditions, the Lamp Operation Hours timer will

freeze and “LAMP FAILURE” will show on the LCD display. The Red LED will

illuminate. If a solenoid valve is connected to the UV power source, it will close on

an alarm condition.

The system will remain in this state until a new lamp is detected. (See “Replacing

the UV Lamp and Cleaning the Quartz Sleeve” in the Operating and Maintenance

section)

NOTE:

The UV power source is designed to shut down if the AC input voltage is

outside its operating limits. When a lamp failure alarm is activated you

should unplug the unit from the AC power source, wait fifteen seconds and

then reconnect the AC power source. If the failure was due to the “Out of

Limits AC Power”, the unit will re-ignite the lamp and operate normally.

Total Running Hours:

The UV power source tracks total running hours of the UV system. The timer shows

00000 hrs on the display at the system’s initial start. The Red LED will be lit when

the timer is approaching the maximum lamp service life 9000 hours. Indicating it is

time to replace the lamp. If an optional solenoid is used on the system, it will close

when the lamp reaches 9000 hrs. It will remain closed until a new lamp has been

installed and the lamp hour timer reset.

Chamber High Temperature Valve:

When the temperature of the water in the chamber exceeds 57 ˚C (135 ˚F); the

thermal relief valve will open until the water temperature goes back to under 57 ˚C

(135 ˚F).

Solenoid Valve Output (Optional)

The UV power source can power a solenoid valve directly, which will stop the water

flow during any system malfunction. The output is 120 vac - 1 amp maximum.

10

OPERATING AND MAINTENANCE

Your Excelight NX UV System is “ON” continuously during normal operation. After

periods of not using your water supply exceeding two to three days, it is

recommended to open all faucets and flush your plumbing system for one to two

minutes.

WARNING!

ULTRAVIOLET LAMP REPLACEMENT

THE ULTRAVIOLET LAMP INSIDE THE REACTOR CHAMBER WILL

OPERATE EFFECTIVELY ROUND THE CLOCK, FOR APPROXIMATELY ONE

YEAR OR 9000 HOURS. THE LAMP WILL NOT LIGHT LONGER THAN THAT,

THE UV LIGHT INTENSITY MAY FALL BELOW THE PRESCRIBED SAFETY

LEVEL. (40MJ/CM2) THEREFORE, ANNUAL LAMP REPLACEMENT IS

NECESSARY REGARDLESS OF APPARENT LAMP CONDITION.

Replacing the UV Lamp and Cleaning the Quartz Sleeve:

A reminder that the chamber will be full of water so have a bucket and towels

handy.

1. Unplug the system from the electrical outlet and turn off the water supply to the

unit. It is advisable to wait 5-15 minutes before proceeding to the next step. The

water in the chamber can heat up to 57 ˚C (135 ˚F);

2. Loosen the thumb screw on the electrical cap and carefully extract the lamp

connector from the electrical end cap assembly to just expose the top of the UV

lamp. While holding the lamp base firmly, disconnect the lamp 4-pin connector.

Gloves should be worn as the lamp base can be very hot. Be careful not to

drop the lamp into the quartz sleeve as both are easily broken.

3. Carefully slide the lamp out of the quartz sleeve and discard.

4. Use caution as the water in the chamber may still be very hot at this stage.

Loosen and remove both end caps. Place a bucket below the chamber and your

hand under the bottom of the sleeve. Using your other hand, carefully remove

the white and black rings from the top of the sleeve. Once the rings are off of

the sleeve top, the sleeve should fall into your lower hand. Carefully extract the

quartz sleeve from the reactor housing. The quartz sleeve is very fragile and

is easily chipped or broken - use extreme caution when installing or

removing it from the reactor vessel.

NOTE:

Do not touch the lamp or quartz sleeve with your fingers. Handle by the ends

only or wear soft non-abrasive gloves.

5. Clean the quartz sleeve with vinegar or a readily available scale-removing

product. (Lime Away, CLR)

6. Examine the quartz sleeve O-rings. If they look worn or cracked, replace them.

Re-install the quartz sleeve. (See replacement parts.)

7. Install new lamp by reversing the procedure described in items #2-4 above.

11

8. Once the unit is re-assembled, Open a tap downstream of the UV. Slowly open

the shutoff valves and purge the air from the system.

9. Ensure there are no leaks at the end caps before connecting the power to the

system. Correct as necessary.

10. Holding the reset button down, turn the unit power on. Continue to hold the reset

button until “LAMP ON” appears on the screen. This will reset the lamp hour

timer to “0000” hrs.

11. If the optional solenoid is being used. Open a tap downstream of the UV. Open

the post UV shut off valve (if installed). Turn the UV system on. Slowly open the

pre-UV shut off valve. Once the UV dosage reaches 40mj/cm2 the solenoid will

open. Check for leaks. If there are leaks, turn UV unit off, close the shut offs,

disconnect the power to the unit, and repair leaks.

SYSTEM REPLACEMENT PARTS

EXCELIGHT NX System Replacement Components

1

Excelight NX8 UV Lamp Standard 4-pin, 9000 hours rated

EL08NSFL

2

Excelight ELNX8 Quartz Sleeve, 532mm SOE, O-rings

included

EL08NSFQ

3

Excelight NX Ballast 115 VAC w/Grounded Plug CSA

Approved

EL08NSFB

4

Excelight Sleeve Cap

EL411C

5

Excelight Electrical Cap

EL411EC

6

Excelight NX mounting Bracket -3.5" Aluminum 2 piece

EL08NSFMB

7

Excelight NX Quartz Sleeve O-Ring Kit

EL08NSFRK

8

Excelight NX Thermal Relief Valve Brass

EL08NSFV

9

Excelight NX Thermal Relief Valve Adapter SS

EL08NSFVA

10

Excelight NX8 Flow Restrictor 8 gpm 3/4"Fpt SS

EL08NSFFR

11

Excelight NX Ultraviolet Transmittance Sensor ½”

EL08NSFTS

12

(Optional)

Excelight NX Shut Off Solenoid- 120vac ¾” FPT Normally

Closed SS

Call

Dealer

12

UV DOSAGE CHART FOR 3-LOG ORGANISM INACTIVATION

Approximate ultraviolet energy levels at 254-nanometer units wavelength required

for 99.9% destruction of various microorganisms UV energy in mWs/ cm² (1mj/cm²

= 1000 mWs/cm²):

BACTERIA

MOULD SPORE

mWs/ cm²

mWs/ cm²

Agrobacterium

tumefaciens

8,500

Aspergillus flavus

(yellowish green)

99,000

Bacillus anthracis

8,700

Aspergillus

glaucus (bluish

green)

88,000

Bacillus mrgaterium

(vegetative)

2,500

Aspergillus niger

(black)

330,000

Bacillus mrgaterium

(spore)

52,000

Mucor

ramosissimus

(white gray)

35,200

Bacillus subtillis

(vegetative)

11,000

Penicillum

digitatum (olive)

88,000

Bacillus subtillis (spore)

58,000

Penicillum

expensum (olive)

22,000

Clostridium tetani

22,000

Penicillum

roqueforti (green)

26,400

Corynebacterium

diptheriae

6,500

Rhizopus nigricans

(black)

220,000

Echerichia coli

7,000

Legionella bozimanii

3,500

Legionella dumoffii

5,500

Legionella gormanii

4,900

ALGAE

Legionella micdadel

3,100

Chlorella vulgaris

(algae)

22,000

Legionella longbeachae

2,900

Legionella pneumophila

3,800

Legionella interrogans

(infectious jaundice)

6,000

Mycobacterium

tuberculosis

10,000 PROTOZOA

Neisseria catarrhaiis

8,500

Nematode eggs

92,000

Proteus vulgaris

6,600

Paramecium

200,000

Pseudomonas

aeruginosa (laboratory

strain)

3,900

13

BACTERIA

Pseudomonas

aeruginosa

(environmental strain)

10,500

Salmonella enteritidis

7,600

VIRUS

Salmonella paratyphi

(Enteric fever)

6,100

Bacteriophage

(E. coli)

6,600

Salmonella

typhimurium

15,200

Hepatitis virus

8,000

Salmonella typhosa

(Typhoid fever)

6,000

Influenza virus

6,600

Sarcina lutea

26,400

Poliovirus

21,000

Serratia marcescens

6,200

Rotavirus

24,000

Shigella dysenteriae

(Dysentery)

4,200

Tobacco mosaic

virus

440,000

Shigella flexneri

(Dysentery)

3,400

Virus of

Infectious

Hepatitis

8,000

Staphylococcus

aureus

7,000 YEAST

Streptococcus faecalis

10,000

Baker's yeast

8,800

Streptococcus

hemolyticus

5,500

Brewer's yeast

6,600

Streptococcus lactis

8,800

Common yeast

cake

13,200

Streptococcus viridans

3,800

Saccharomyces

ellipsoideus

13,200

Vibrio cholerae

6,500

Saccharomyces

sp.

17,600

A 16mj/cm² dose is suitable for reducing non-pathogenic nuisance organisms only.

A 30mj/cm² Industry Standard Dose - This is the dosage produced by 2.5" diameter

disinfection chambers when designed using the 1966 US Department of Health UV

disinfection Policy Statement.

A 40mj/cm² dosage is now required in NSF/ANSI Standard 55.

14

UV DISINFECTION LIMITED WARRANTY

One-Year Limited Warranty for the UV Chamber

Waterite, Inc. warrants the UV chamber on the Excelight product to be free from defects in material and workmanship for a

period of one (1) year from the date of purchase. During this time, we will repair or replace, at its option, any defective

Excelight UV chamber. Please return the defective part to an Excelight dealer, who will return it to Waterite, Inc. We will

either make the necessary repairs or, if it is determined that a replacement is required, we will provide a replacement part.

We will then return the part to the dealer. This warranty does not include shipping and handling charges which will be

collected from you by the dealer. Parts repaired or replaced under this one (1) year warranty will be covered under warranty

to the end of the original one (1) year warranty period. This warranty is also subject to the conditions and limitations outlined

under the heading "General Conditions and Limitations" below.

Seven-Year Limited Pro-Rated Warranty for Structural, Hardware and Electrical Components

Waterite, Inc. warrants the structural, hardware, and electrical components to be free from defects in material and

workmanship for a period of seven (7) years pro-rated from the date of purchase. During this time, we will repair or replace,

at its option, any defective parts covered by the warranty. Please return the defective part to an Excelight dealer, who will

return it Waterite, Inc. We will either make the necessary repairs or, if it is determined that a replacement is required, we

will provide a replacement part. We will then return the part to the dealer. This warranty does not include shipping and

handling charges which will be collected from you by the dealer. Parts repaired or replaced under this seven (7) years pro-

rated warranty will be covered under warranty to the end of the original seven (7) years pro-rated warranty period. This

warranty is also subject to the conditions and limitations outlined under the heading "General Conditions and Limitations"

below.

One-Year Limited Warranty for Lamps, Sleeves and UV Sensors

Waterite, Inc. warrants original lamps, sleeves and UV sensors to be free from defects in material and workmanship for a

period of one (1) year from the date of purchase. During this time, we will repair or replace, at its option, any defective parts

covered by the warranty. The warranty period for lamps and sleeves may be verified using date codes in addition to purchase

receipts and Waterite, Inc. database of registered owners. We will advise you whether the defective item needs to be

returned to an Excelight dealer for failure analysis. Replacement lamps and sleeves provided under warranty will be sent to

your Excelight dealer. If the UV sensor experiences a problem which Waterite, Inc. confirms is covered by warranty, please

return the sensor to an Excelight dealer who will return it to us. We will either repair or replace the sensor and return the

sensor to your dealer. This warranty on lamps, sleeves and sensors does not include shipping and handling charges which

will be collected from you by the dealer. Parts replaced under this one (1) year warranty will be covered under warranty to

the end of the original one (1) year warranty period. This warranty is also subject to the conditions and limitations outlined

under the heading "General Conditions and Limitations" below.

Warranty for Replacement Lamps and Parts

Waterite, Inc. warrants replacement lamps, purchased for annual routine maintenance, and other parts purchased to repair

product components that are no longer covered by the original warranty, to be free from defects in material and workmanship

for a period of three (3) months from the date of purchase. During this time, we will repair or replace, at its option, a defective

replacement lamp or part free of charge except for shipping and handling charges. The warranty period on replacement

lamps and parts will be verified using date codes and/or purchase receipts. Waterite, Inc. will advise you whether the

defective item needs to be returned to an Excelight dealer for failure analysis. Replacement lamps and parts provided under

warranty will be sent to your Excelight dealer.

General Conditions and Limitations

None of the above warranties cover damage caused by improper use or maintenance, accidents, acts of God or minor

scratches or imperfections that do not materially impair the operation of the product. The warranties also do not cover

products that are not installed as outlined in the applicable Owner's Manual. The limited warranties described above are the

only warranties applicable to the Excelight products listed in the "Specific Warranty Coverage" section. These limited

warranties outline the exclusive remedy for all claims based on a failure of or defect in any of these products, whether the

claim is based on contract, tort (including negligence), and strict liability or otherwise. These warranties are in lieu of all

other warranties whether written, oral, implied or statutory. Without limitation, no warranty of merchantability or of fitness for

a particular purpose shall apply to any of these products. Waterite, Inc. does not assume any liability for personal injury or

property damage caused by the use or misuse of any of the above products. Waterite, Inc. shall not in any event be liable

for special, incidental, indirect or consequential damages. Waterite, Inc.’s liability shall, in all instances, be limited to repair

or replacement of the defective product or part and this liability will terminate upon expiration of the applicable warranty

period.

Pro-Rated Warranty

The pro-rated warranty as specified in this document is applicable according to following parameters:

All the warranties are 100 % valid at the time of the sale, and effective the day of the registration of the warranty. The

decrease in covered percentage occurs the day after the anniversary date of the purchase of the UV System (as long as

the warranty has been registered and valid). The prorated portion of an eligible warranty repair is based on the date that

the problem is communicated to the dealer in writing, or of the day when the UV System enters the dealer and/or Waterite,

Inc. for repairs, or the date determined by the dealer (subject to Waterite, Inc.’s approval). If during a repair started at a

higher prorated percentage, a second repair is requested or necessary and is under warranty at a lower proportion, the

lower proportion will be applicable. The fact of not having registered the warranty will not prolong in whole or in part the

warranty, the starting date of your warranty is always the date of purchase.

REGISTER YOUR PRODUCT ONLINE AT WATERITE.COM OR FILL OUT

THE INCLUDED PRE-PAID, SELF ADDRESSED POSTCARD.

15

WATERITE, INC.

Winnipeg, Manitoba

Canada

www.waterite.com

Table of contents

Other Waterite Water Filtration System manuals

Waterite

Waterite BLACKMAXX RB8 User manual

Waterite

Waterite Vectapure NX Installation instructions

Waterite

Waterite VECTAPURE RSX II User manual

Waterite

Waterite VECTAPURE 360 Installation instructions

Waterite

Waterite TriPlex DuPlex FS-BB Series Installation instructions

Waterite

Waterite Vectapure RSXII LITE User manual

Waterite

Waterite VECTAPURE RSX User manual

Waterite

Waterite Excelight EL411AK User manual

Waterite

Waterite VECTAPURE NX RO4053HNX Installation instructions

Waterite

Waterite Vectapure II RO-4042H Installation instructions