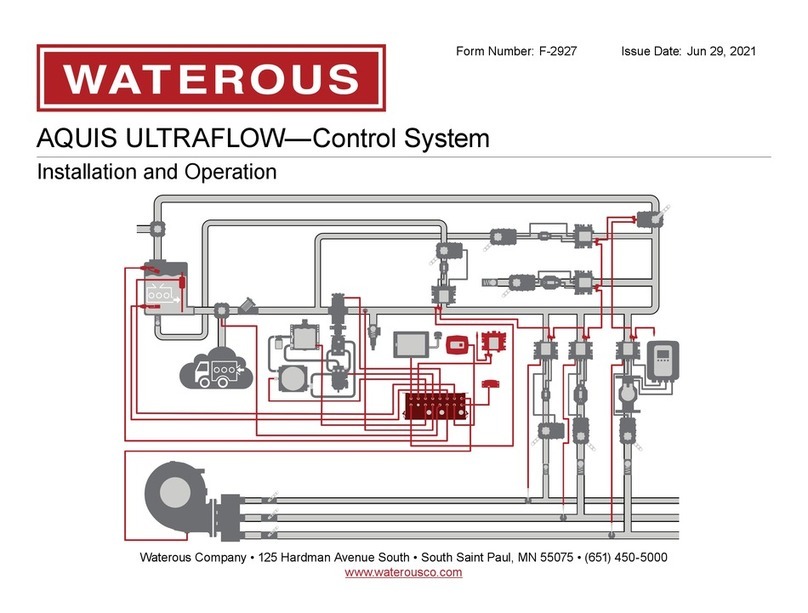

Waterous, Arizona Operations Aquis 2.5 SSP Installation & Operation Rev 3

Page 3 of 30

Table of Contents

SECTION 1. SAFETY, Everyone’s Concern..........................................................................................4

SECTION 2. INSTALLATION PLANNING.............................................................................................5

SECTION 3. PLUMBING COMPONENTS.............................................................................................7

A. Motor / Pump Assembly....................................................................................................................7

I. Power Supply................................................................................................................................8

II. Motor / Pump / Controller..............................................................................................................9

III. Pump Maintenance.....................................................................................................................10

B. Wye Strainer....................................................................................................................................10

C. Flow Sensor ....................................................................................................................................10

D. Flow Tee..........................................................................................................................................11

E. Foam Injection Check Valve...........................................................................................................12

F. Drain Lines......................................................................................................................................12

G. Flushing System..............................................................................................................................12

H. Inject/Bypass Valve.........................................................................................................................13

SECTION 4. ELECTRICAL COMPONETS..........................................................................................14

A. Operator Interface Terminal (OIT)...................................................................................................15

B. Flow Sensor ....................................................................................................................................16

C. Cables.............................................................................................................................................16

SECTION 5. CALIBRATION AND SETUP...........................................................................................17

A. Entering Calibration Mode...............................................................................................................17

B. F1 - Default Mix Percentage ...........................................................................................................17

C. F2 –Units of Measurement.............................................................................................................17

D. F3 –Flow Rate Calibration..............................................................................................................18

E. F4 –System Lockout .......................................................................................................................18

F. F5 –Foam Select............................................................................................................................18

G. F6 –Simulated Water Flow (per NFPA testing)..............................................................................19

H. Saving Calibration...........................................................................................................................19

SECTION 6. OPERATION...................................................................................................................20

A. Operating the System .....................................................................................................................20

SECTION 7. DRAWINGS.....................................................................................................................25

SECTION 8. PART LIST......................................................................................................................29

SECTION 9. CONDITIONAL 1-YEAR WARRANTY POLICY..............................................................30

Figure(s)

Figure 1 AQUIS 2.5 SSP Motor / Pump assembly ......................................................................................7

Figure 2 Terminal block locations................................................................................................................9

Figure 3 Small Terminal Block......................................................................................................................9

Figure 4 Paddle-wheel Tee........................................................................................................................11

Figure 5 Foam Injection Check Valve.........................................................................................................12

Figure 6 Flow sensor..................................................................................................................................16

Figure 7 Basic System Schematic.............................................................................................................25

Figure 8 OIT (Display) Panel Cutout..........................................................................................................26

Figure 9 Aquis SSP Z Bracket Mount Bolt Pattern....................................................................................27

Figure 10 Aquis Flow Tees........................................................................................................................28