USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

2

FCC Statement

This device complies with part 15 of the FCC rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

Changes or modifications not expressly approved by Hayward could void the user’s authority to oper-

ate this equipment.

NOTE:This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause harmful interference to radio

or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

-- Reorient or relocate the receiving antenna.

-- Increase the separation between the equipment and receiver.

-- Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

-- Consult the dealer or an experienced radio / TV technician for help.

Industry Canada Statement

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

The term “IC” before the certification / registration number only signifies that the Industry Canada

technical specifications were met.

Before you Begin

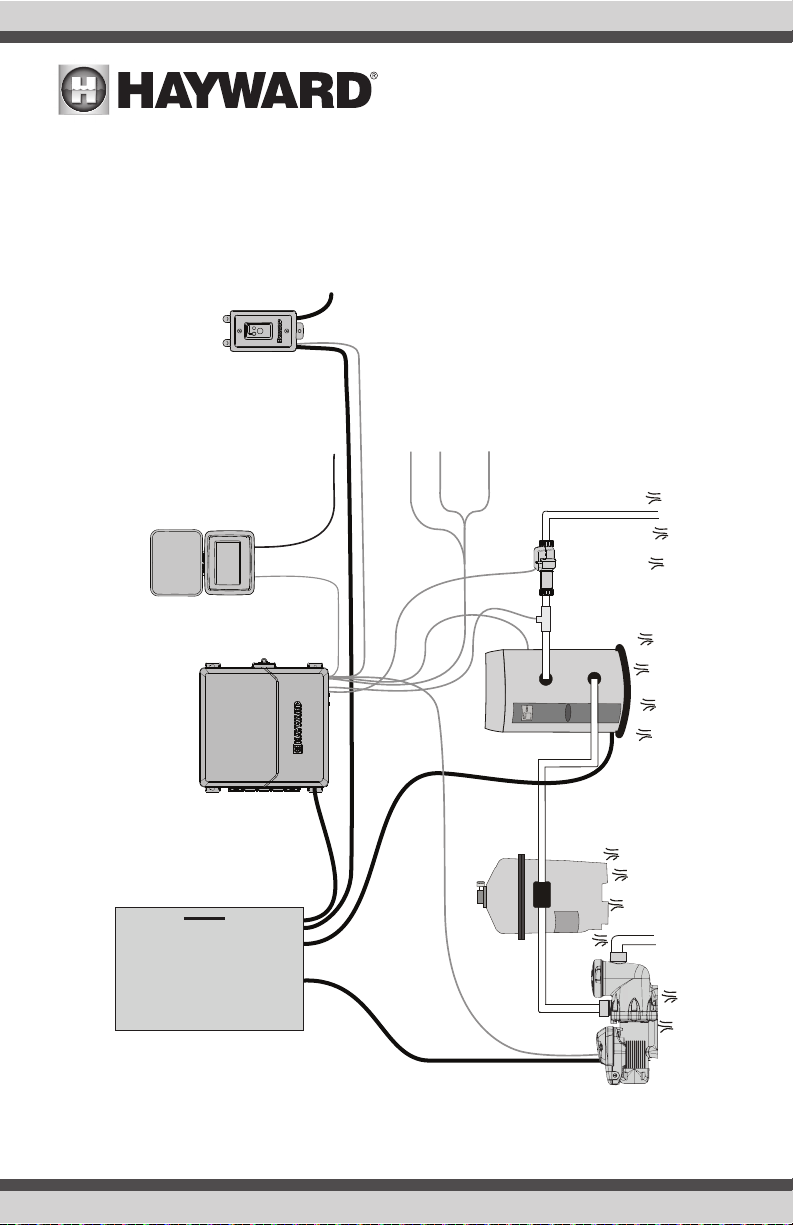

The AQR S3 Omni® is a web enabled pool automation control with a convenient touchscreen interface

and chlorine generation features. Automatically and remotely control pumps, heaters, valve actua-

tors, pool and yard lighting, pool chemistry equipment and more. The AQR S3 Omni offers the next

generation of technology to manage pool/spa equipment, allowing communication to web connected

computers, tablets and mobile devices. You can now conveniently monitor your pool/spa and change

settings anytime, and from anywhere.

Using the chlorine generator feature requires a concentration of salt (sodium chloride) in the pool water.

The AQR S3 Omni automatically sanitizes your pool by converting the salt into free chlorine which

kills bacteria and algae in the pool. Chlorine will revert back to sodium chloride after killing bacteria.

These reactions will continuously recycle virtually eliminating the need to add sanitizing chemicals to

your pool. The only time you may need to add more salt to the pool is when water is replenished due

to backwashing, draining, or splashing (not evaporation).

The AQR S3 Omni also provides control functions adding convenience to pool and spa management.

Built in functions include variable speed filter pump control, single and two speed filter pump control,

heater control, valve control, pool cover detection, and more.