Igema SMLC 1 User manual

Low water level

limiter SMLC1

With level electrode

EL 030 / EL 19-2

D-08-B-166 -1

Edition 07/11

Installation and operating instructions

2

-Table of contents-

1. Risks and Safety precautions 3-4

1.1 General safety instructions ....................................................... 3

1.2 Exclusion of liability ..................................................................

2 Use in compliance with regulations

3. Function SMLC1 -6

3.1 Operating principle ................................................................... 6

4. Design 7

.1 Installation dimensions and descriptions...................................... 7

. Installation 8

6. Configuration 8

7. Fitting the electrode 9-11

7.1 Fixing elements for receiving electrodes ............................... 10-12

7.2 Mounting in mounting housing ............................................ 12-13

7.3 Adjusting the electrode plugs ................................................... 1

7. Shortening the electrode extension........................................... 1

8. Power connection 1 -16

8.1 Wiring diagram ...................................................................... 15

8.2 Procedure.............................................................................. 16

8.3 Testing.................................................................................. 16

9. Technical Data 16-17

9.1 Device data ...................................................................... 16-17

9.3 Maximum ratings of potential free contacts................................ 17

10 Appendix 18

10.1 Warranty............................................................................... 19

11 EC Declarations of conformity 20

3

General safety instructions

1. Avoidance of risks to persons and property

• Only use the device supplied in accordance with the intended planning.

• Extensions and modifications to the device must only be carried out with our approval.

• Observe accident prevention regulations and system-specific safety instructions.

• Read and observe assembly and operating instructions.

2. Limitations of use

The device must only be used in accordance with the details in these operating

instructions or for the parameters agreed in the supply contract (see name plate) and the

application.

3. Avoidance of risks and damage

• Disseminate the assembly and operating instructions to the departments responsible

for “goods in, transport, assembly, commissioning and maintenance”.

• If this device is passed on to third parties these assembly and operating instructions in

the relevant language of the country must accompany it.

• Work on the device should only be carried out by trained staff specially commissioned

and exclusively with the current disconnected.

• Read and observe the assembly and operating instructions carefully and keep them in a

safe place.

• Take note of and follow the safety instructions printed in bold and highlighted

in the individual sections!

• When transporting, avoid e.g. knocks and putting down heavily, this can lead to

damage.

• For intermediate storage ensure that the storage location is suitable for the device.

The storage location must be dry and the device secured against damage.

4. Symbols

In these assembly and operating instructions safety instructions are specially marked

with the following symbols:

means that if they are not observed there is risk to life and / or

significant damage to property may occur.

Danger

means that attention is particularly drawn to technical requirements.

Take note

Exclusion of liability

IGEMA GmbH Mess- und Regelsysteme will assume no liability if the above-mentioned

regulations, instructions and safety precautions are not noted and followed.

5

2. Use in compliance with regulations

The self-monitoring low water level limiter SMLC1 in combination with the level

electrodes EL 030 or EL 19-2 is a multi-dynamic limiter of a special type in

accordance with DIN VDE 0116 and Wasserstand 100. The self-monitoring

control system (SMC) enables first failure identification at the time of occurrence

and immediately switches off the downstream relays.

3. Function

The general function of the limiter SLMC1 is displayed by lighting of the green

LED “UB”. The input stage of the SMLC1 compares the values of the isolation

and limiter electrode in a Wheatstone bridge using a mains synchronised

reference voltage. The dimensioning of this stage allows the identification of

short circuits and interruptions in the electrode power line. The core element of

this limiter is a timer and control unit monitoring the output of the input stage in

the rhythm of 0 ms for its in-phase dynamic behaviour.

If the behaviour is correct the timer and control unit activates the driver of the

final stage with its own momentum. The final stage has its own specified time

which only activates the output relays when phasing and time of the activation

are carried out within a fixed framework. The power flowing via the contacts of

the safety chain is limited in the SMLC1 by amp fuse protection by which

sticking of the contacts is prevented. With static activation or failure of the

activation the final stage will switch off after a delay time.

Faults and lack of water are displayed by the lighting up of the red LED

“FAULT”. In the case of lack of water after a time delay of one second together

with the display “FAULT” the contacts of the additional fault reporting are

closed. After the delay time that can be set at , 8, 12, 16 seconds switch-off of

the relays of the safety chain takes place. Locking must be carried out on site.

The delay time is set at seconds.

6

3.1 Operating principle SMLC1

The SMC system is capable of identifying any possible first failure the moment it

occurs and switching off the downstream relays. Failure to detect a fault is

therefore impossible.

As further dynamic monitoring, the periodic overall test of the device takes place

every 2 minutes for one second as a fully automatic process. The yellow LED

“TEST” shows that the test is being carried out followed by confirmation by the

red LED “FAULT” lighting up briefly.

Because of this special first failure safe design manual tests are not necessary so

there are no test switches on the SMLC1.

Alarm Safety chain

Mains

Electrode

7

4. Design

The SMLC1 is supplied in a plastic plug-in housing for fitting into switch cabinets.

The housing is designed for quick fitting with a spring catch for the DIN EN

50022 standard 35 mm carrier rail and for screw fixing on a mounting plate.

4.1 Installation dimensions and descriptions SMLC1

Base Front view Side view

with connecting terminals

1 Screws for snap fastening

2 Holes, ø .3 mm

3 Fixing screws

Snap fastening

5 Holder

6 Cable feedthrough

7 Hood

SMLC1

8

. Installation

Secure with protection class in accordance with current regulations

!

With snap fastening for standard 3 mm carrier rail

according to DIN EN 0022

•Fix device on standard carrier rail by means of the snap fastening ( ).

•Release fixing screws (3) and pull hood (7) from holder (5).

Without snap fastening

•Release fixing screws (3) and pull hood (7) from holder (5).

•Release screws (1) and remove snap fastening ( ). Drill through the

marked point (2) in the holder (5) with ø .3 mm drill.

•Fit base (5) on base plate with two M screws.

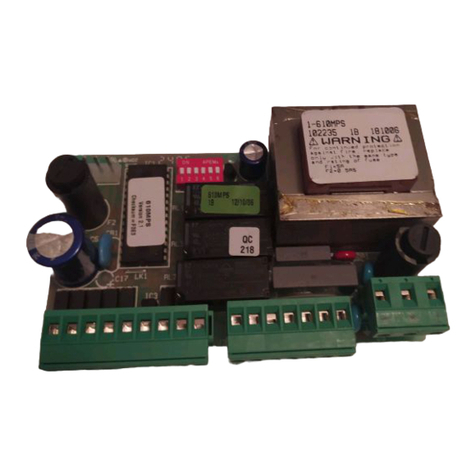

6. Configuration

The preset switch-off time can be changed.

It is to be agreed with the local expert.

Setting the switch-off time:

•Open SMLC1. To do this release the fixing screws (3) and pull the hood

(7) off the holder (5) – with the device disconnected from the power

supply.

•After unlatching the back plate pull the circuit board sandwich out of the

hood (7). On the smaller circuit board at the front edge there is a two-

pole DIP switch (see diagram) via which the switch-off time can now be

changed as follows:

DIP switch Switch-off

1 2 time

off off s

on off 8 s

off on 12 s

on on 16 s

Circuit board

sandwich

DIP switch

9

7. Fitting the electrode

It is essential to remove the protective tube for transport before

installation!

If several electrodes are screwed into a flange the electrode plug (2)

and the associated electrodes should be labelled to prevent confusion!

Fixing the electrode extension (9)

Push the electrode extension (9)

approx. 30 mm over the electrode shank

(8) until the ø .3 mm hole

matches the threaded hole

in the electrode shank.

Screw up both parts by means

of the enclosed M set screw with

SW2 hexagon socket.

Screwing in the electrode

•Release screw (1) and pull off

electrode plug (2).

•Clean sealing surfaces and check

•Insert sealing ring (6)

•Lubricate thread (7) with heat-resistant

solid lubricant (e.g. graphite).

•Screw in electrode and tighten,

max. tightening torque Md=1 0 Nm.

On commissioning the boiler

check the electrode screw connection

in the flange for tightness and if necessary

retighten!

1 Screw

2 Electrode plug

3 Seal

4 Contact carrier

5 Threaded ring

6 Sealing ring

7 Thread

8 Electrode shank

9 Electrode extension

10

7.1 Fixing elements for receiving the electrodes

The flanges, seals, screws and nuts listed in the table below are laid out in

accordance with the Technical Rules for Steam Boilers (TRD) and tested by the

Technischen Überwachungsverein (TÜV) [Technical Inspection Agency].

Flange according to DIN

Drilling plans 1-8

“Bohrbild” means: drilling plan

Seals according to DIN

PN DN DIN Sealing

surface Form Threaded hole Material

0 2635 B

63 2636

100 / 160

50

2638

DIN 2526 E

according to drilling

plan

1,2

1.0 60

0 2635 B

63 2636

100 / 160

100

2638

DIN 2526 E

according to drilling

plan

1,2,3, ,5,6,7,8

1.0 60

PN DN DIN Material

0 EN 151 -1 IBC

asbestos-free

63

100 / 160

50 2697 RSt 37-2/ 0.5

graphite

0 EN 151 -1 IBC

asbestos-free

63

100/160

100 2697 RSt 37-2/ 0.5

graphite

11

DIN screws

PN DN DIN Numbe

r

Dimension Material

0 M16 x 75

63 M20 x 100

100/160

50 976

M2 x 110

1.7709

0 M20 x 90

63 976 M2 x 110 1.7709

100/160

100

2510

8

LM27 x 1 5 Ck 35

DIN nuts

PN DN DIN Numbe

r

Dimension Material

0 M16

63 M20

100/160

50 EN

2 032

8

M2

1.7258

0 M20

63

EN

2 032

M2 1.7258

100/160

100

2510

16

NFM27 C 35

12

7.2 Mounting in mounting housing

The approval is only valid if shut off valves are mounted between the

process connections of the mounting house and the boiler supports and

a relief valve is fitted on the mounting housing!

Illustration Mounting Housing

13

Construction dimensions

Materials

Flanges 1.0 60

Pipes St35.8 / 16 Mo 3 (according to pressure range)

Process connection M1

PN DN DIN Sealing form DIN

16

25

0

2635 2526 Form C

63

100 2637

160

50

100

2638

2526 Form E

Process connection M2

PN DN DIN Sealing form DIN

16

25

0

20 2635 2526 Form C

63

100 2637

160

25

2638

2526 Form E

On request ASME-compliant flanges, weld-on ends or

DIN or ASME-compliant socket welding on the process connection are also an

option.

Construction dimensions min. [

[[

[mm]]

PN DN ∅

∅∅

∅d C D A1 A2

16

25

0

115 85

63 100

100 105

160

50 60.3

135

15

115

100

16 100

25

0

1 0 150

63 1 0

100 155

160

100 11 .3

160

15

165

160

1

7.3 Adjusting the electrode plugs (see sketch page 9)

If insertion of the electrode plugs (2) is not possible because of the position of

the contact carrier ( ), take the following steps:

•Keep releasing the threaded ring (5) until the contact carrier ( ) can be lifted.

•Turn the contact carrier ( ) into the required position and snap in;

retighten the electrode plug (5).

7.4 Shortening the electrode extension (see sketch page 9)

Never dismantle the electrode when the boiler / mounting housing is

pressurised!

•Release screw (1) and pull off electrode plug (2).

•Screw out electrode.

•Dismount electrode extension (9) by screwing out the set screw.

•Clamp electrode extension (9) directly at the point to be shortened and

shorten. Do not distort the electrode extension!

Lengthening is not permissible!

Do not heat insulate electrode head - all parts above the thread (7)!!

15

8. Power connection

Carry out connection according to the SMLC1 wiring diagram on the

back plate of the hood (see page 7 item 7) or according to the wiring

diagram illustrated.

8.1 Wiring diagram (EL 030, EL 19-2)

See name plate of supply voltage

Safety chain

Alarm

Power connection:

Shielded connection line

e.g. LIHF/GLS 4 x min. 0.75 mm²

Cable connection at the

electrode socket EL03 or EL019-

1 Schraube

2 Electrode plug

3 Seal

4 Contact carrier

5 Threaded ring

6 Connecting cable

16

8.2 Procedure

•Pierce or pull out cable feedthrough (6) and feed connection cable through.

Check supply voltage. See name plate for allowable voltage. Use shielded

connection cable to the electrode 2 x 2 STP, e.g. LIHF/GLS,

x 0.75 mm².

•Length of connecting line max. 100 m at 5 – 10,000 µS/cm or max. 30 m at

0.5 – 2,000 µS/cm.

•Only connect shielding on the SMLC1 control unit (terminal 6). After electrical

connection - with device disconnected from the mains - put hood (7) on

holder (5) and tighten fastening screws (3).

(see sketch p. 7)

8.3 Testing

Switch on supply voltage, the green LED "U

B

” lights up.

•When the electrode is uncovered the red LED lights up “FAULT”.

•When the electrode is submerged the LED “FAULT” must not light up.

•The LED "TEST" must light up for one second every two minutes.

A successful test is confirmed by the red LED flashing briefly.

9. Technical data

9.1 Device data

Component

TÜV ID: 000006173

CE ID no.: 0035

Manufacture in accordance with EC Directive 97/23/EC,

Modules B+D, Category IV, EC type test W 17/02,

Applied standards:

Control device: DIN EN 50081-1, DIN EN 50082-1

Electrode TRD, AD2000, ASME boiler

230 V ± 15%

Mains connection

50/60 Hz

Power consumption approx. .5 VA

Device fuse 80 mA/T

Protection in accordance with DIN VDE 0 70 IP 0*

Allowable ambient temperature 0 - 60°C

* IP 5 protection class is to be ensured in the boiler area to comply with the German regulation

VdTÜV-Wasserstand 100, .90.

17

Electrode EL 030 EL 19-2

Nominal pressure PN 25 0 63 100 160 250 320

Max. allowable pressure PS [bar] 20 32 50 80 100 160 250

Max. allowable temperature TS [°C] 21 239 265 296 312 3 6 367

Construction dimensions Y

[mm]

> 125 > 130

Mechanical connection Thread G ½

Power connection Plug connection with screw terminals, strain relief

Screw cable connection M16X1.5

Protection class in accordance with DIN

VDE 0 70

IP 65

Allowable ambient temperature at the

plug [°C] 100°C

Construction

dimensions Y

[mm]

EL 030 / EL 19-2

1.700 with protective tube > DN 80, vertical installation position

800 with protective tube DN 50, vertical installation position

800 with protective tube DN 50 / 100, installation position inclined up to 5°

9.2 Maximum ratings of potential free contacts

Safety chain Switching voltage max. 250 V AC

switching current max. A resistive

max. 0.75 A inductive cos ϕ0.5

Additional fault reporting Switching voltage max. 250 V AC

switching current max. 8 A resistive

max. 1.5 A inductive cos ϕ0.5

Electrical conductivity 5 µS/cm ≤ æ ≤ 10,000 µS/cm

of the fluid 0.5 µS/cm ≤ æ ≤ 2,000 µS/cm

Length of the max. 100 m at 5 – 10,000 µS/cm

connecting cable max. 30m at 0.5 - 2,000 µS/cm

Electrode EL 030 EL 19-2

Insulator PTFE Ceramic

Plug Polyamide

(glass fibre reinforced)

Sealing ring Soft iron

Electrode housing Niro

Electrode rod Niro

Electrode extension Niro

18

10. Attachment

Warranty

We give a guarantee period on our product of 2 months. The condition for this

is proper handling in accordance with the assembly and operating instructions.

For worn and replacement parts the warranty is limited to defects of material

and manufacture.

Level electrodes are wearing parts and do not form part of the warranty.

19

11. Declaration of Conformity

EC conformity declaration in accordance with

EC Directive 2006/9 /EC,

EC Directive EMC 2004/108/EC and DIN EN 60730-1+2

We:

IGEMA GmbH

LECOS GmbH

J.G. Merckens Mess- und

Regelsysteme GmbH & Co. KG

Zieglerstraße 10-16

D-52078 Aachen

declare as the IGEMA Group that the

product “NW water level limiter” as pressure accessory

Product type:

Control device “SMLC1” with

Electrode “EL030” or “EL19-2”

comply with the directives and have been subjected to the following conformity-assessment

procedure:

Category IV, Modules B and D

Applied standards:

Control device: DIN EN 50081-1, DIN EN 50082-1

Electrode/float switch: TRD, AD2000

Notified body for the modules:

TÜV Rheinland Industrieservice GmbH

Am Grauen Stein

D-51105 Köln (Cologne)

Identification no. 0035

Aachen, 20.07.2011

E.H. Kilchert A.Scholl J.Riechelmann

(Managing director) (QM Officer) (Development)

20

This high-quality IGEMA product was designed, manufactured and

tested with the application of the QM System guidelines in accordance

with DIN EN ISO 9001:2000.

If the device supplied shows transport damage or gives cause for

complaint in spite of our final quality control please contact our

SERVICE department by return.

Telephone 0241- 5687-0.

Prepared by: V.Hugemann Approved: Date: 20.07.2011

Table of contents

Other Igema Control System manuals

Popular Control System manuals by other brands

Waterous

Waterous Aquis 2.5 SSP Installation & operation instructions

OSI Security Devices

OSI Security Devices OM100 installation instructions

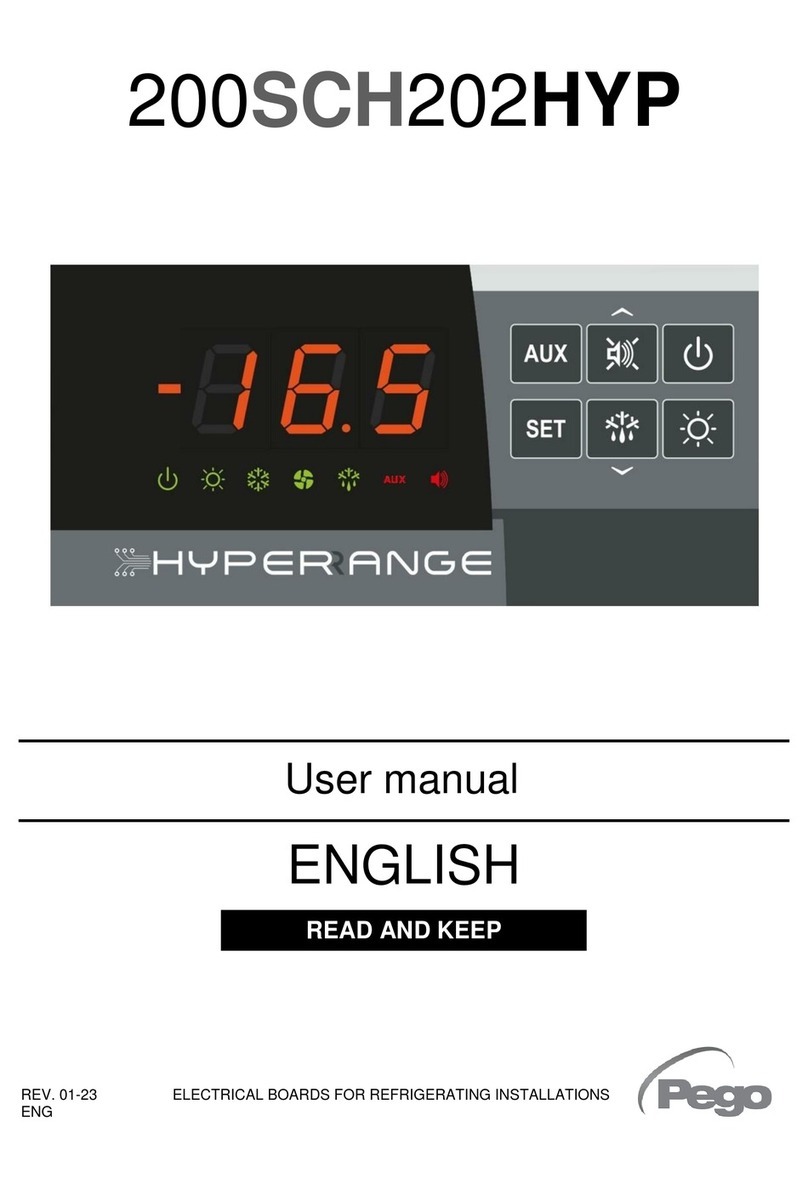

Pego

Pego 200SCH202HYP user manual

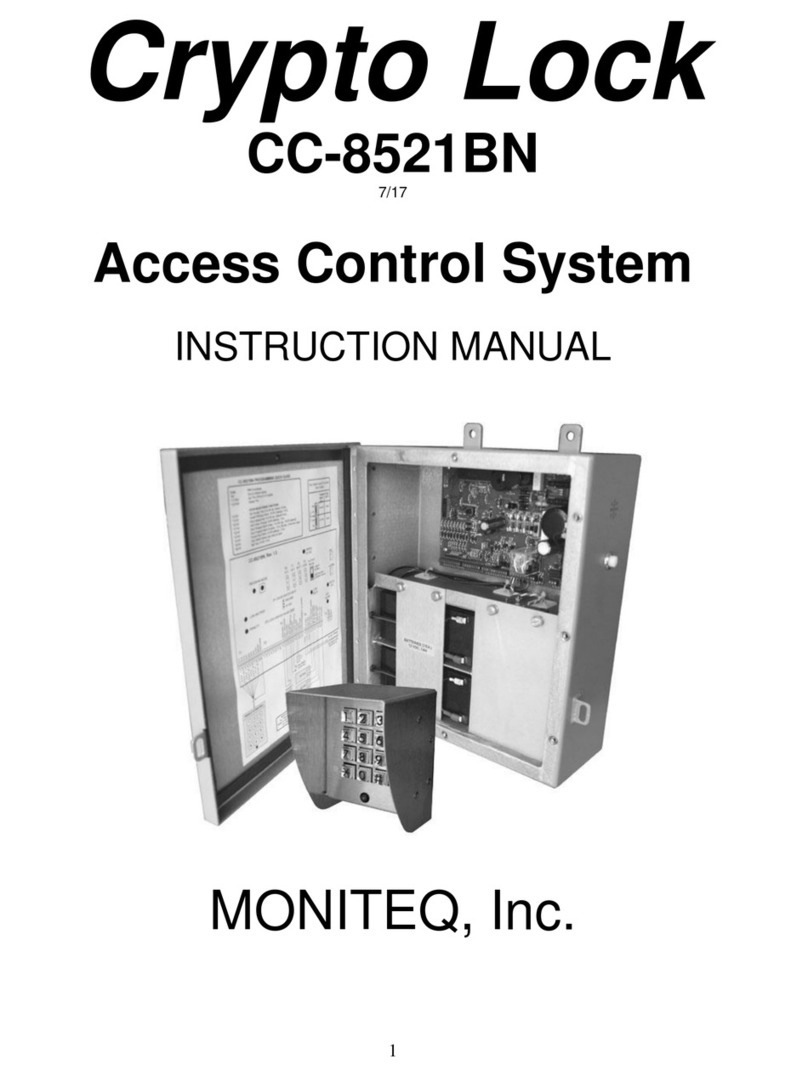

Moniteq

Moniteq Crypto Lock CC-8521BN instruction manual

Lindsay

Lindsay FIRLDNET GSM CELLULAR RTU installation manual

SOMFY

SOMFY SOLIRIS Uno installation guide