WaterRower M1 SERIES User manual

PREVENTATIVE MAINTENANCE

AND TROUBLESHOOTING GUIDE

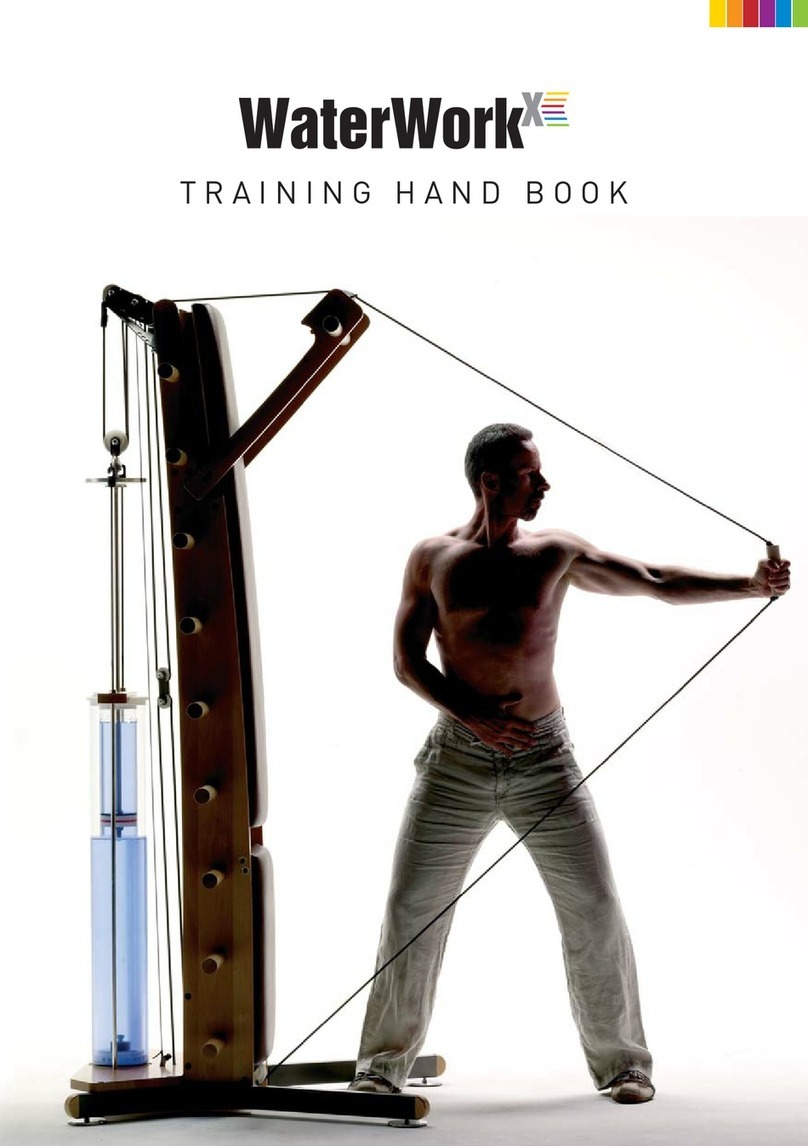

Congratulations on becoming a WaterRower Owner. This guide will

help make sure your WaterRower M1 unit is kept in good condition

and functioning at all times.

STORAGE

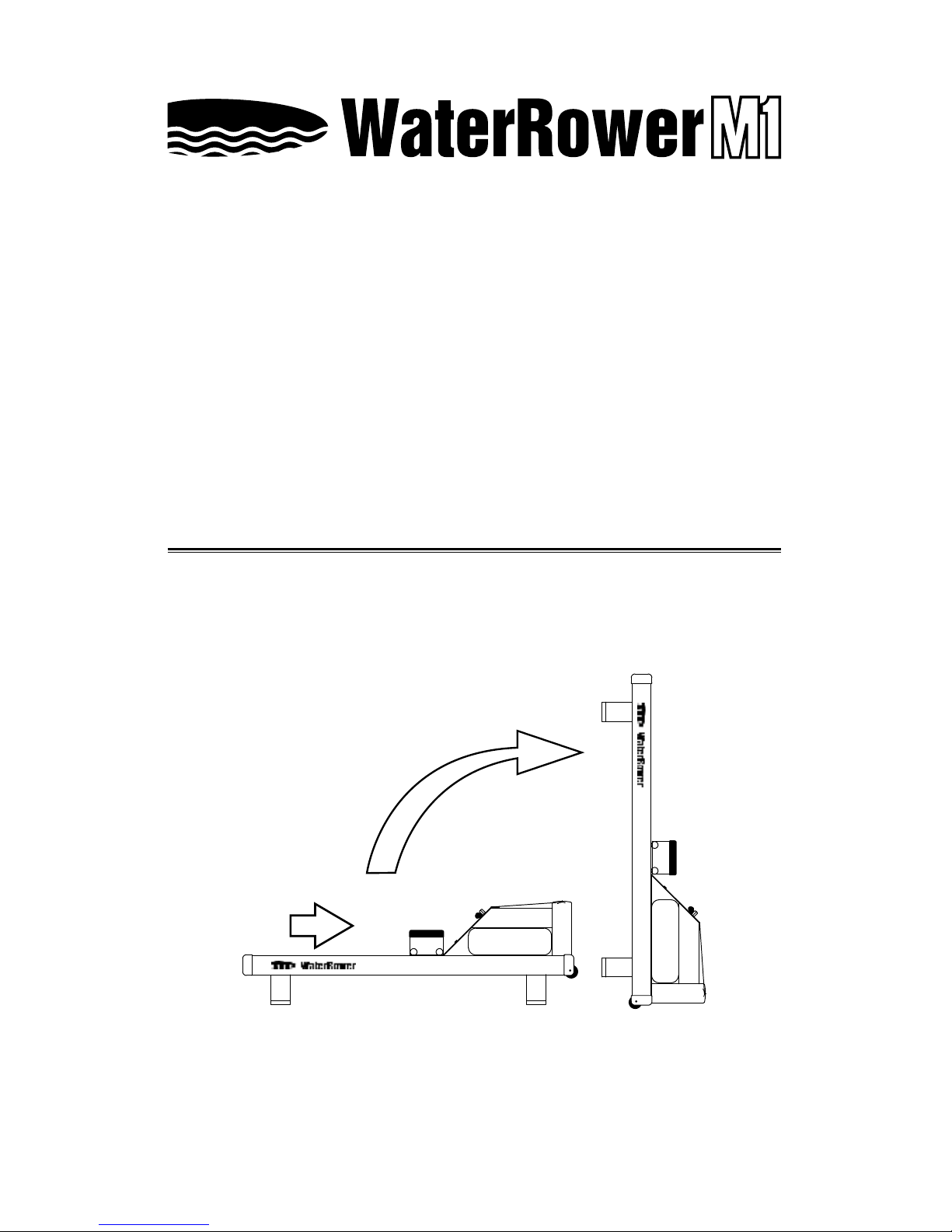

The WaterRower can be stored upright. To do so, lift the end of the

rower and move the WaterRower on the front wheels to the area of

storage.

Please note, when standing your unit upright, slide the seat forward

towards the footboard prior to lifting the rower.

2

3

Table of Contents

MAINTENANCE PAGE

Daily Maintenance............................................... 4

Weekly

Dust Build Up................................................... 4

Loose Bolts...................................................... 4

Alignment of the Belts...................................... 4

Quarterly

Clean Seat Wheels.......................................... 5

Check Tension of Recoil.................................. 5

Every 6 Months

Water Condition............................................... 5

Tank Stopper in Place...................................... 5

Every 1-2 Years

Replace Batteries............................................. 7

Replace Bungee.............................................. 7

TROUBLESHOOTING

Monitor................................................................. 10-11

Paddle................................................................. 12

Recoil.................................................................. 13

Seat.................................................................... 13

Water Discoloration............................................. 13

Noise................................................................... 14

Tank.................................................................... 14

4

MAINTENANCE SCHEDULE

DAILY MAINTENANCE

or after each workout

Cleaning

Wipe down handle, seat, rails and frame after

every row.

WEEKLY

Inspect the WaterRower M1

Dust Build Up

Dust tank and belts regularly.

Clean the top of the rails where the wheels run.

To do this, run a damp cloth along the top and

sides of the rails. This will remove the dirt, dust,

etc. which builds up with use.

In addition, clean any residue or build-up that has

accumulated on the wheels.

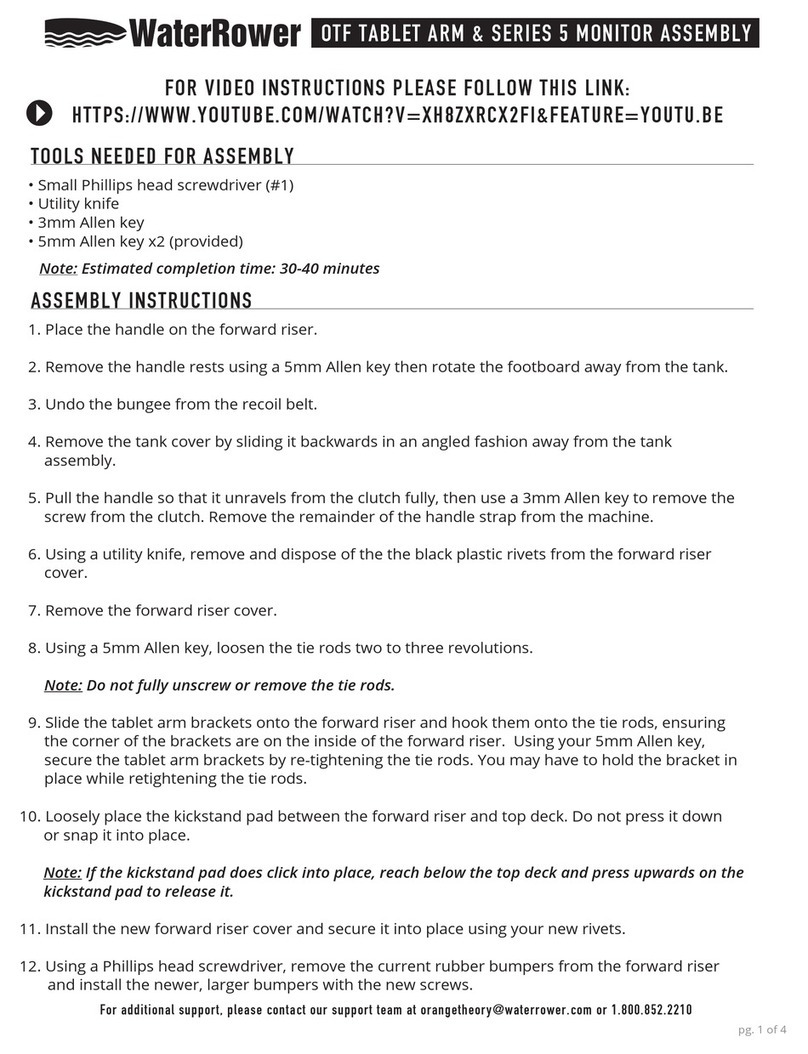

Loose Bolts

Each week, inspect the bolts along the tank

assembly and rail assembly to ensure they are

all secure in the frame of the rower. If necessary,

use a 5mm allen key to tighten any bolts that have

come loose.

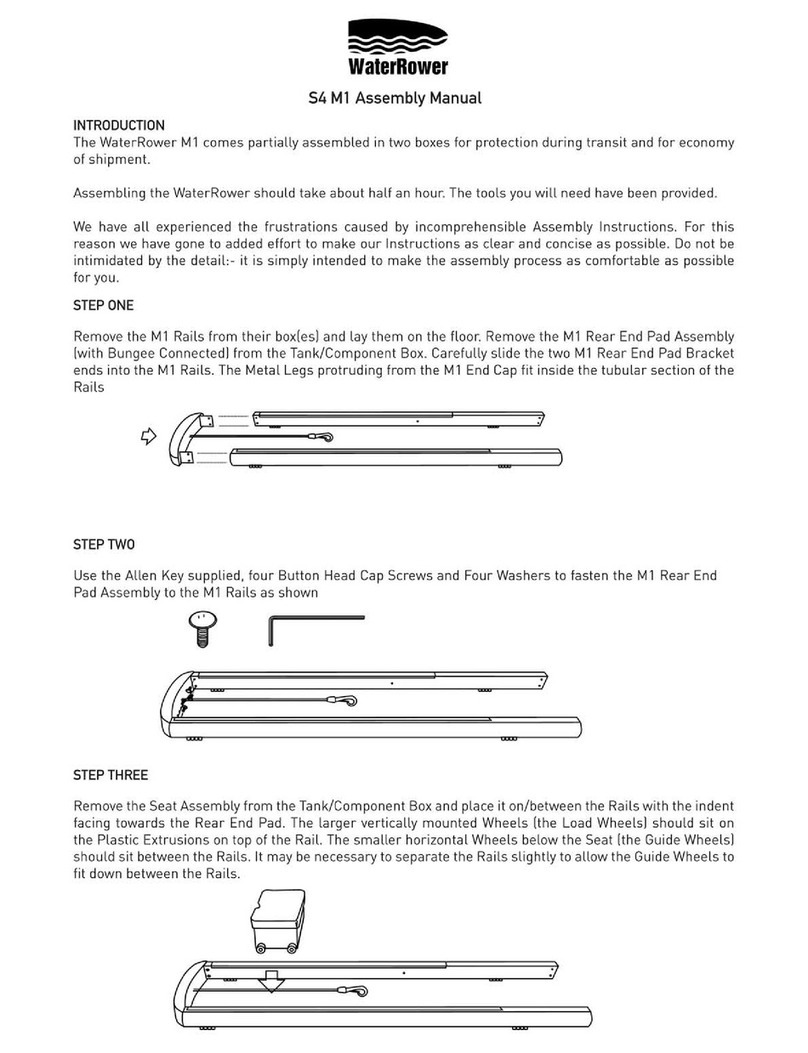

Weekly Belt Alignment and Monitor Test

On a weekly basis, row several strokes on the

rower to check the alignment of the recoil belt;

it can, sometimes, come misaligned on the front

pulleys (see picture).

If the recoil belt is off a pulley, the recoil of the

handle will be sluggish and not feel smooth. It can

also lead to fraying of the belt. If the recoil feels

misaligned, check that the recoil belt is aligned

and runs over each pulley correctly and smoothly

as seen in the second picture.

While checking the alignment, review the monitor

to ensure it is working correctly. Turn the monitor

on and it should ash all zeros, indicating it is

ready to start. As you begin rowing, the monitor

should register your stroke rate, speed, distance &

time. If not, please refer to the monitor section in

the troubleshooting guide (page 10).

AlignedMisaligned

5

EVERY MONTH

Handle Strap

Every 6 months, review the stitching and wear on

the handle strap. If you notice excessive wear,

replace the handle. Fraying can be caused by

incorrect use. Please see instructions on our

service site for replacing the handle.

EVERY 3 MONTHS

Check the Tension of the Recoil

To test the strength of the recoil, rst remove the

top deck cover. Next, lift the handle out of the

handle rests and release the handle so it slides

along the top deck cover, towards the forward

riser pulley. The handle should slide smoothly and

quickly all the way to the front.

If the recoil is sluggish or slow, please refer to

page 13 to troubleshoot.

6

EVERY 6 MONTHS

Water condition

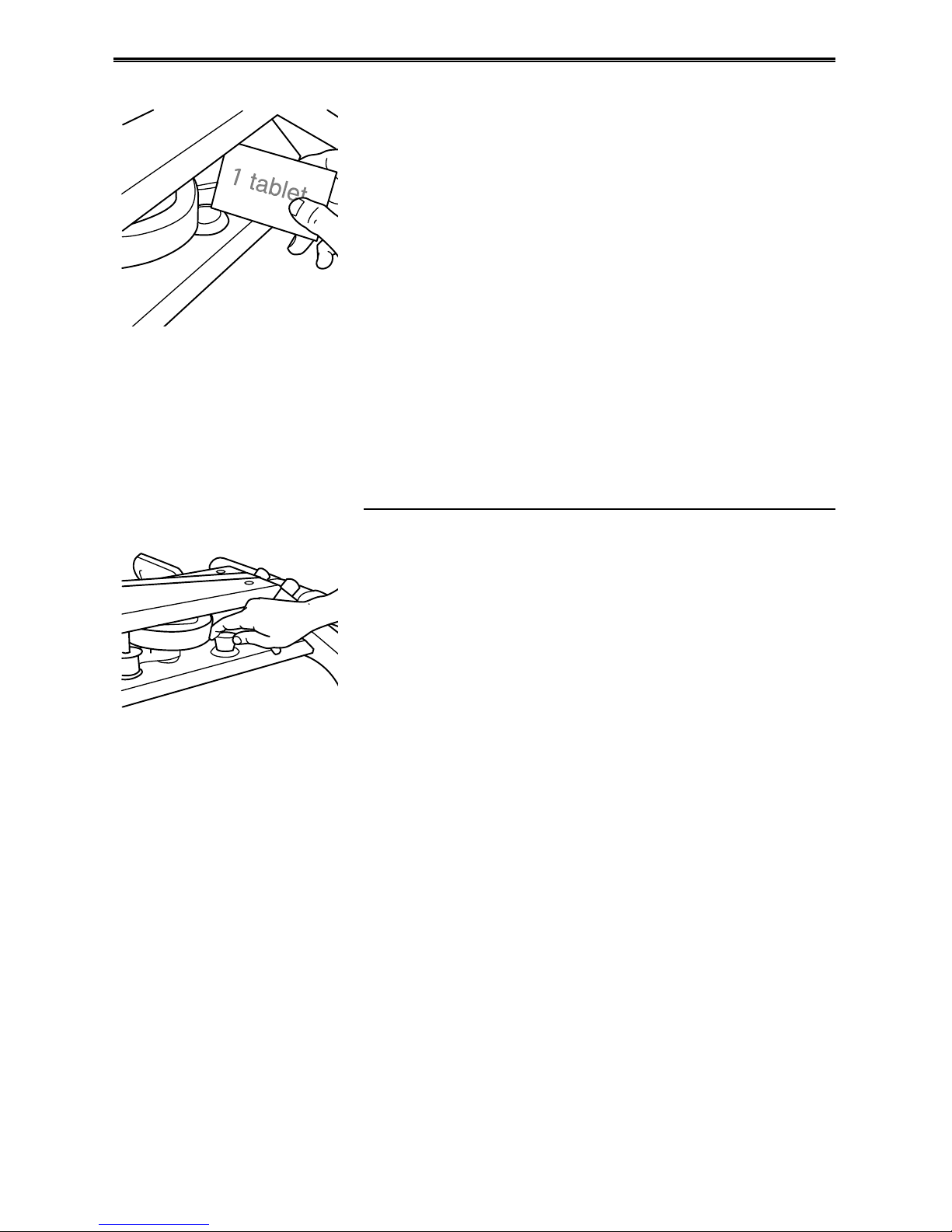

We have included purication tablets in the kit. We

recommend adding 1 tablet to the water every 6

months. If the water turns cloudy and the tablet

does not clear up the water, then it may be best to

change out the water. Please use the hand syphon

pump and refer to our service website on how to

remove the water.

*Note: If you use the blue dye in your tank, it is not

recommended that you use the purication tablets.

Discoloration may occur if you do so. Instead,

please visually monitor water quality and change

when necessary. It is recommended that dyed

water is changed out every year.

Tank Stopper

The tank stopper can fall out, on occasion. If this

occurs, you will need to reinsert it into position.

Moisten the tank stopper to help with putting it

back into position.

7

EVERY 1 TO 2 YEARS

Replace the Batteries

If the monitor readings begin to fade or are

incorrect, we recommend changing the batteries.

Four AA batteries are located behind the monitor.

Using a Phillips screwdriver, unscrew the two

screws, one on left and one on the right of the

monitor, and gently lift to access the battery pack

located behind the monitor. Check the batteries

are positioned correctly in the battery pack.

Replace the batteries and reattach the screws to

the monitor housing.

Replace the Bungee

Over time, and with use, the bungee cord can

lose its elasticity, which will affect the recoil of the

machine. If this happens, it should to be replaced.

To perform this task, detach the bungee from

the recoil belt. Next, remove the two horizontally

positioned bolts with the 5mm allen key from the

bungee pod.

Remove the old bungee assembly and position

the new one into place on the rear bumper.

Replace the two horizontally positioned bolts with

5mm allen key.

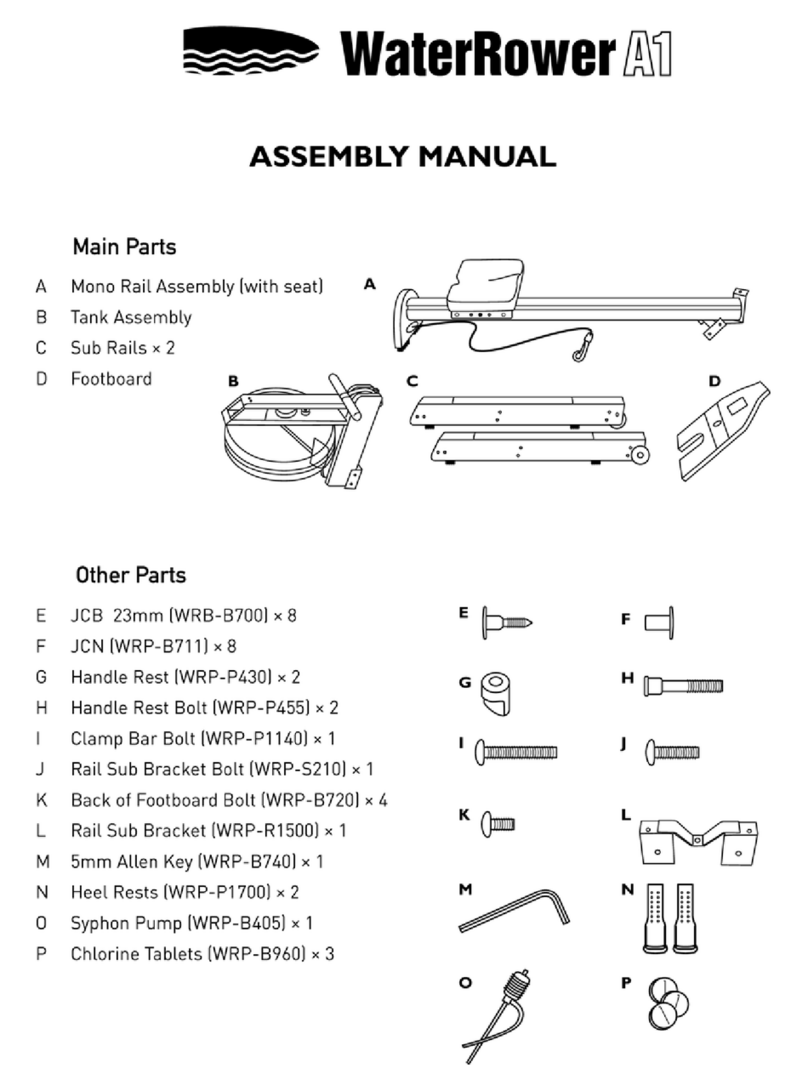

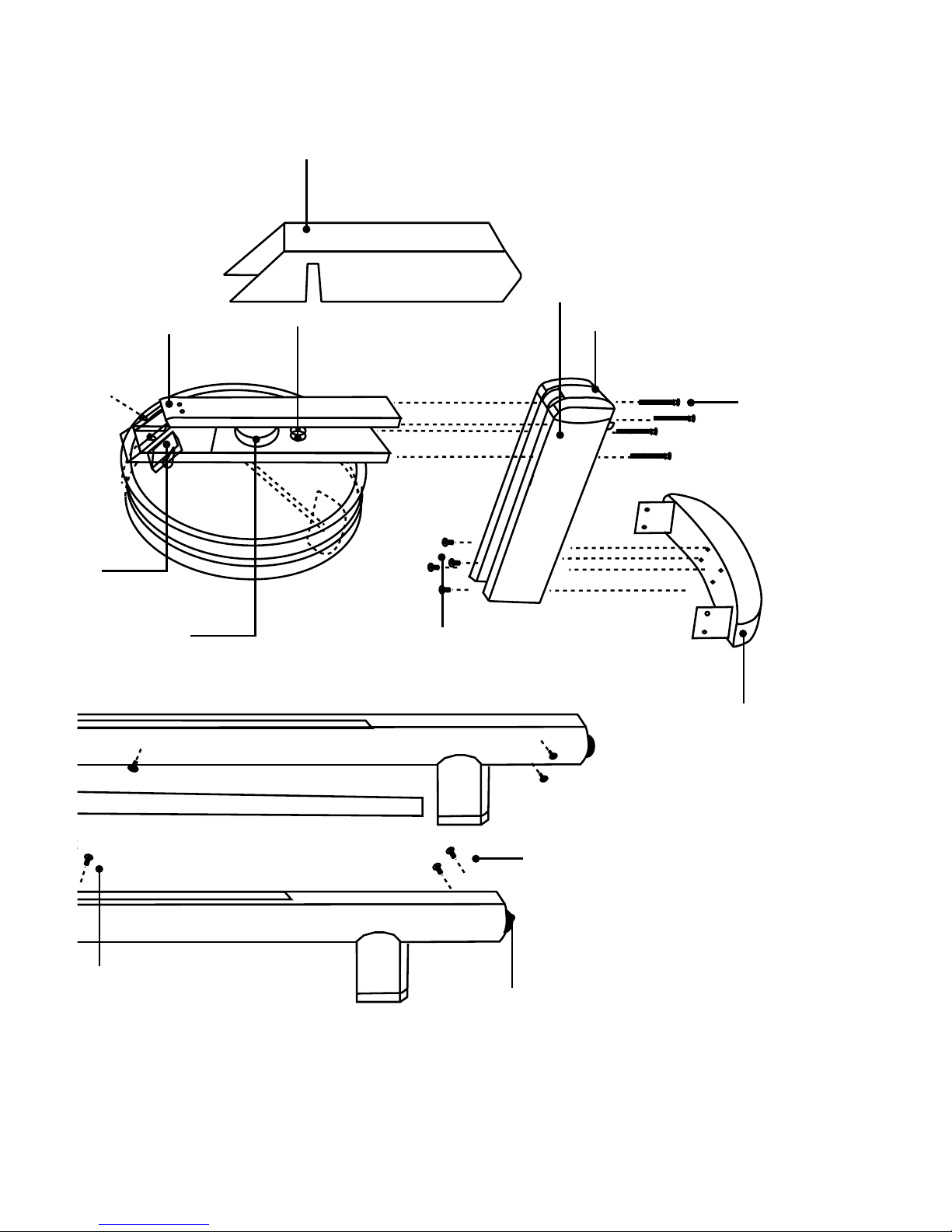

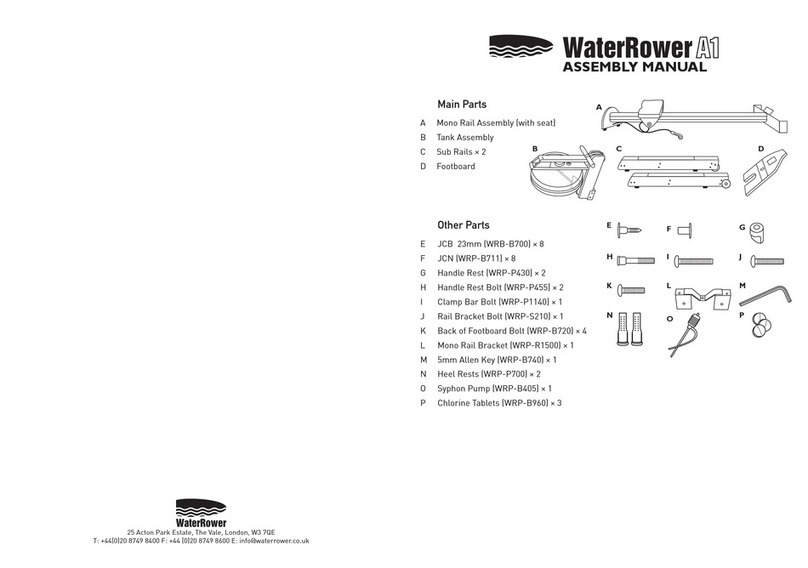

M1 SERIES EXPLODED VIEW

WRPH1100

17” Handle Assembly

WRPS000M1

Seat Assembly

WRPB300

Guide Pulley

Forward Riser

Top Deck

Top Deck Cover

WRPT004

Tank Assembly

with Clutch

WRPB510

M1 Front End

Pad Assembly

WRPB505

M1 Button

Screw Kit

WRPB520

M1 Rear End

Pad Assembly

WRPB510

M1 Button Head

Cap Screw and

Washer Set

WRPK500

M1 Bungee Assembly

WRP-P455

WRP-P430

Handle Rest Bolt Set (2)

Handle Rest Set (2)

WRP-P1720 M1

Coverplate

WRP-P1710

Footstrap

Assembly

WRP-P100

WaterRower

Emblem

WRP-P1700

Heelrest/

Footpad Set

(2)

WRP-P715

Footstrap Assembly

WRP-P1715

M1 Cover Plate Screw Set (4)

WRP-P725

M1 Footboard

Spacer Set (2)

WRP-P1000M1

M1 Footboard

S4 Monitor

WRPD510

M1 Dolley

Wheel Set (2)

WRPF500

M1 Forward

Riser Cap

WRPT730

Tie Rod

Assembly (4)

WRPB505

M1 Button Head

Cap Screw &

Washer Set

WRPS201

M1 M8x30mm

Button Cap Screws

WRPB905

Recoil Belt

M1 SERIES EXPLODED VIEW

WRPH1100

17” Handle Assembly

WRPS000M1

Seat Assembly

WRPB300

Guide Pulley

Forward Riser

Top Deck

Top Deck Cover

WRPT004

Tank Assembly

with Clutch

WRPB510

M1 Front End

Pad Assembly

WRPB505

M1 Button

Screw Kit

WRPB520

M1 Rear End

Pad Assembly

WRPB510

M1 Button Head

Cap Screw and

Washer Set

WRPK500

M1 Bungee Assembly

WRP-P455

WRP-P430

Handle Rest Bolt Set (2)

Handle Rest Set (2)

WRP-P1720 M1

Coverplate

WRP-P1710

Footstrap

Assembly

WRP-P100

WaterRower

Emblem

WRP-P1700

Heelrest/

Footpad Set

(2)

WRP-P715

Footstrap Assembly

WRP-P1715

M1 Cover Plate Screw Set (4)

WRP-P725

M1 Footboard

Spacer Set (2)

WRP-P1000M1

M1 Footboard S4 Monitor

WRPD510

M1 Dolley

Wheel Set (2)

WRPF500

M1 Forward

Riser Cap

WRPT730

Tie Rod

Assembly (4)

WRPB505

M1 Button Head

Cap Screw &

Washer Set

WRPS201

M1 M8x30mm

Button Cap Screws

WRPB905

Recoil Belt

10

TROUBLESHOOTING

MONITOR The Monitor Turns On but Does Not Start

Check the connection of the sensor cable and the

monitor cable. Check that the wiring on both the

monitor and sensor cable is intact.

Remove the top deck cover and check the position

of the sensor disk underneath the top deck.

It may be necessary to shift the sensor disk up to

a position that is closer to the optical sensor. To do

so, use a at instrument to gently raise the disk up.

Remove handle

rests so the

footboard

swings back.

Sensor Sensor Disk

11

Frozen Monitor Screen

If the monitor screen is frozen, statistics stay the

same or if the monitor does not turn off, remove

the batteries for 10 seconds and replace the

batteries.

If the problem persists, contact your

nearest WaterRower ofce or email:

support@waterrower.com.

If the monitor does not turn on, it could mean the

batteries are faulty and need to be replaced. To

replace the batteries refer to page 7.

If the monitor does not turn on after replacing the

batteries or there is a break in the wires, contact

you nearest WaterRower ofce or email

support@waterrower.com for replacement parts.

Erratic Numbers

If the monitor is reading higher than usual

numbers, we recommend trying the following:

1. Using a can of compressed air, spray the

sensor disk and clean the sensor (you may

need to remove the top deck).

2. Use a dryer sheet or anti-static spray to clean

the sensor and sensor disk.

3. If in direct sunlight, move your WaterRower to

the shade. The S4 sensor is optical and light

may interfere with readings.

4. Check for loose wires in the wire harness

between the monitor and sensor.

5. Replace the 4 AA batteries, erratic numbers

can result due to low battery power.

6. Check the sensor disk for misaligned teeth.

7. Replace the sensor and sensor disk.

12

PADDLE Tank Paddle is Rubbing

First, remove the top deck cover.

With the 5mm allen key, loosen all the bolts (in the

order of: 1, 2, and 3) on the tank assembly. Take a

few gentle pulls to see if rubbing continues.

If rubbing has stopped, gently retighten the bolts in

the same order. Replace the top deck cover.

If this does not solve the problem, determine

where the paddle is rubbing in the tank: right side/

left side, top/bottom or front/back of the tank.

Please refer to the Troubleshooting section on our

Service website www.waterrowerservice.com, or

contact your nearest WaterRower ofce. You can

email: support@waterrower.com.

2 - Forward

Riser Bolts

3 - Inner Rail Bolts

1 - Top Deck Bolts

Remove handle

rests so the

footboard

swings back.

13

RECOIL

Sluggish Recoil

First, remove the top deck cover and check

the belt alignment to make sure all straps are

positioned correctly on the pulleys.

Second, when the handle is in its full forward

position next to the forward riser pulley. Check the

recoil belt is wound 1½ times around the shaft of

the paddle, underneath the clutch.

Third, shorten the recoil strap by readjusting the

strap in the buckle. Be careful not to make the

recoil belt too short, as the connector may catch

on the forward riser.

Replace the bungee cord if necessary (refer to

page 7).

Please contact support@waterrower.com or call

your nearest WaterRower ofce to order a new

bungee.

SEAT Ensure the seat is correctly positioned on the rails.

The rail extrusions and the guide wheels are under

the lip on the extrusion. If the seat does not slide

smoothly with rst use, check the rails are clean

and free from obstruction. If the seat feels rough,

clean the rails and the seat wheels.

If the problem persists, please contact your

nearest WaterRower ofce, or email:

support@waterrower.com.

Wrapped 1½

times around

Load

Wheels

Guide

Wheels

14

WATER DISCOLORATION If the water begins to turn cloudy, add in one

purication tablet.

If after two weeks the water has not cleared, drain

the water from the tank, ll the tank with fresh

water and add in a purication tablet.

*Note: If you use the blue dye in your tank, it is not

recommended that you use the purication tablets.

Discoloration may occur if you do so. Instead,

please visually monitor water quality and change

when necessary. It is recommended that dyed

water is changed out every year.

NOISE Rower Makes Noise While Rowing

When taking the rst few pulls on your rower, the

only sound you should hear is the swishing of

the water. If there are any other sounds, please

determine where the sound is coming from and

contact your nearest WaterRower ofce (details on

back page).

TANK Tank is Leaking Water

First check the level of water is not lled above the

maximum level. Please refer to the level gauge

sticker on the side of the tank.

If the tank is lled to the correct level, determine

where the water is coming out of the tank and

contact your nearest WaterRower ofce or email

support@waterrower.com

15

To help a customer service representative expedite your call, please have your

serial number available; the serial number of your rower can be found on a silver

sticker attached to the back of your monitor

For easy reference, write your serial number below:

S/No:

Made in USA

SN: 000000

WaterRower

US +1 (401) 247 7742 • UK +44 (0)20 8749 9090

DE +49 (0)5921 1798400 • NL +31 (0)180 590697

FR +33 (0)3.20.67.20.07 • IT +39 0422 307016

ES +34 91 640 7004 • AU +61 (0) 2 9681 4221

www.waterrower.com

WRM7074

United Kingdom

19 Acton Park Estate

The Vale, London W3 7QE

Tel: +44 (0)20 8749 9090

info@waterrower.co.uk

www.waterrower.co.uk

United States

560 Metacom Avenue

Warren, RI 02885

Tel: +1 (401) 247 7742

info@waterrower.com

www.waterrower.com

Australia

72 South Street

Rydalmere NSW 2116 Australia

Tel: +61 (0)2 9681 4221

info@waterrower.com.au

www.waterrower.com.au

Other manuals for M1 SERIES

4

Table of contents

Other WaterRower Fitness Equipment manuals

WaterRower

WaterRower WOODEN DUAL RAIL Installation instructions

WaterRower

WaterRower OTF GEN 2 ROWER User manual

WaterRower

WaterRower Indo-row A1 User manual

WaterRower

WaterRower S4 M1 User manual

WaterRower

WaterRower M1 SERIES User manual

WaterRower

WaterRower S4 User manual

WaterRower

WaterRower S1 User manual

WaterRower

WaterRower WRM7060 User manual

WaterRower

WaterRower Indo-row A1 Use and care manual

WaterRower

WaterRower Indo-row A1 User manual