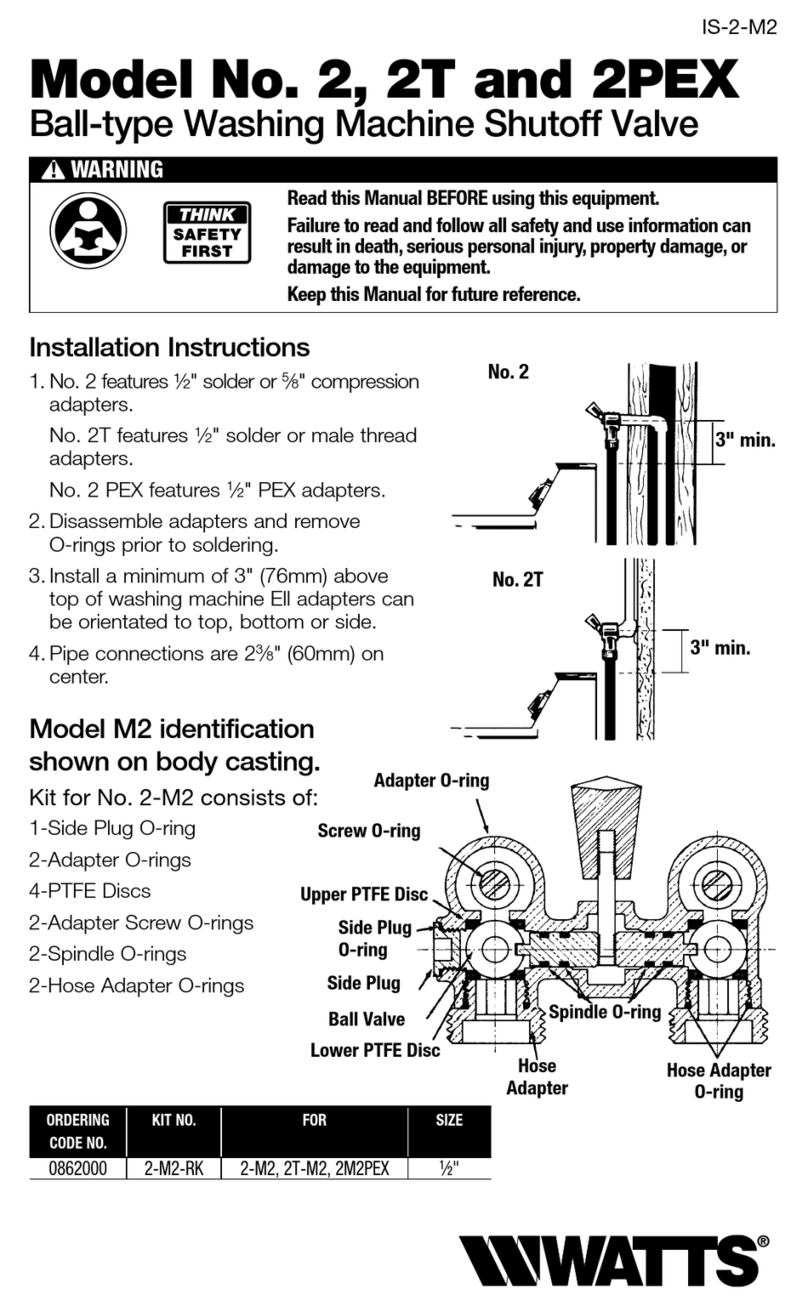

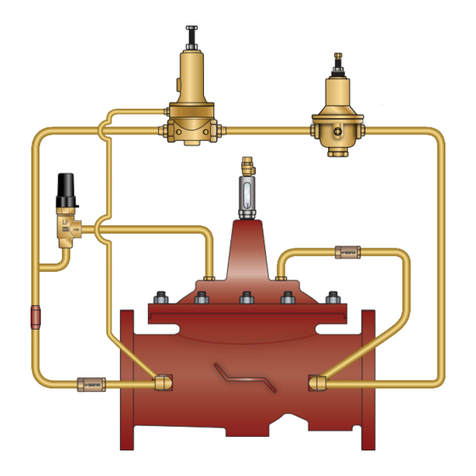

Stem

Seat Cylinder

Integral

Stainless Steel

Valve Seat

Disc

Strainer

Screen

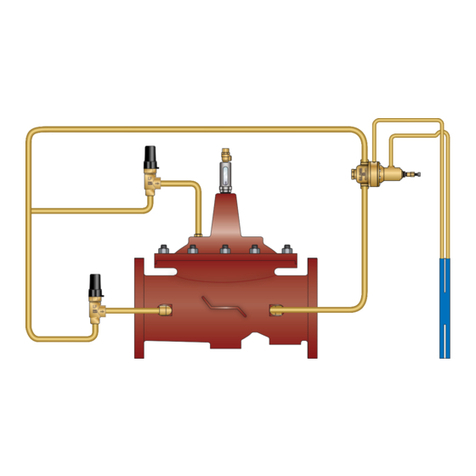

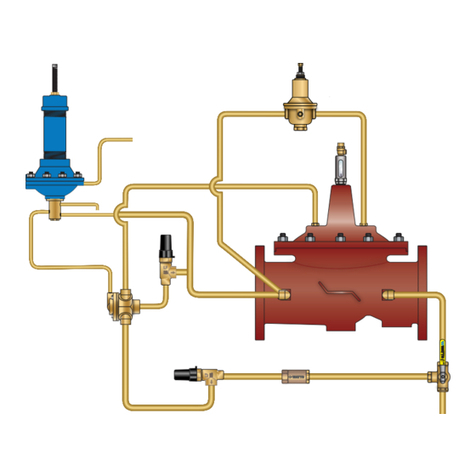

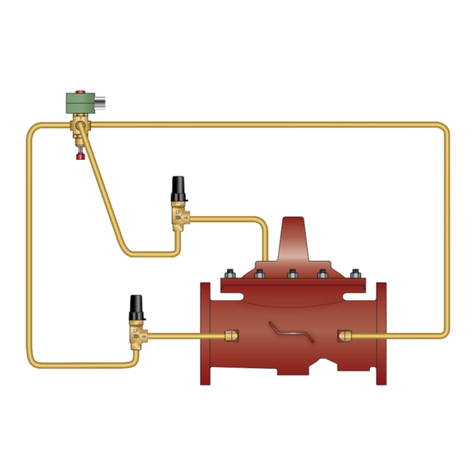

Watts Thermal Expansion “Bypass” model water pressure reducing valves

not only control high water service pressure but also contain an “integral

thermal expansion bypass check valve” which reduces the frequency of relief

valve dripping caused by thermal expansion.

The built-in thermal expansion bypass, another Watts first, operates on the

principle of a check valve in reverse. Normally, the check is held closed by

the street main pressure, preventing any flow of water through it into the

system. However, when thermal expansion pressure increases to just 1 lb.

to 2 lbs. higher than the main pressure, the check valve opens passing the

expanding water back into the supply main at the rate it is expanded. Thus,

the expanding water is dissipated (as in an open system) and the relief valve

is not affected.

NOTICE

Effectiveness of the thermal expansion bypass feature is limited to systems

where the street main pressure is less that the allowable setting of the pres-

sure relief valve. Therefore, its use can be broadened by using a relief valve

with higher pressure setting (providing the working pressure of the tank per-

mits). While this feature limits the conditions causing relief valve dripping, it in

no way replaces a pressure relief valve which is necessary to protect against

other causes of excessive pressure.

The use of a water pressure reducing valve nor-

mally creates a closed system. When water is

heated in a closed system, it expands causing an

increase in pressure. This pressure may increase

to the set pressure of the relief valve (on the water

heater) causing it to drip, thus releasing the ex-

panding water and protecting the system against

excessive pressure. This increase in the system

pressure over that regulated by the reducing valve

is call “thermal expansion pressure”.

Watts thermal expansion bypass model water

pressure reducing valve is an economical solution

of this annoyance, since under certain conditions

it allows the expanding water to escape back into

the supply main before it can affect the relief valve.

Complete Replacement Assembly

(Includes Diaphragm)

When Ordering, Specify:

1. Ordering Code Number

2. Size of Valve

3. Type Number

4. Model Shown on Nameplate

ORDERING

CODE NO.

KIT NO. VALVE SERIES SIZE

INCHES

878377 1⁄2" LFN250RK LF23, LF123, LFN250 1⁄2

878339 3⁄4" LFN250RK LF23, LF123, LFN250, LFN256 3⁄4

Diaphragm

Seat and Disc

Assembly

Kit for No. LF23, LF123, LFN250, LFN250B

includes all items shown.

What is - thermal expansion?

Series LF23, LF123 and LFN250

For additional detailed information on thermal expansion

send for folder F-RV.

IS-2323A 1315 EDP# 1910259 © 2013 Watts

USA: Tel: (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

Canada: Tel: (905) 332-4090 • Fax: (905) 332-7068 • www.watts.ca

Limited Warranty: Watts Regulator Co. (the “Company”) warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date of

original shipment. In the event of such defects within the warranty period, the Company will, at its option, replace or recondition the product without charge.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY THE COMPANY WITH RESPECT TO THE PRODUCT. THE COMPANY MAKES NO OTHER

WARRANTIES, EXPRESS OR IMPLIED. THE COMPANY HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy described in the first paragraph of this warranty shall constitute the sole and exclusive remedy for breach of warranty, and the Company shall not be responsible for any incidental, special

or consequential damages, including without limitation, lost profits or the cost of repairing or replacing other property which is damaged if this product does not work properly, other costs resulting

from labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemical, or any other circumstances over which the Company has no

control. This warranty shall be invalidated by any abuse, misuse, misapplication, improper installation or improper maintenance or alteration of the product.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion or limitation of incidental or consequential damages. Therefore the above

limitations may not apply to you. This Limited Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You should consult applicable state laws to

determine your rights. SO FAR AS IS CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL SHIPMENT.

A Watts Water Technologies Company

WARNING: This product contains chemicals known to

the State of California to cause cancer and birth defects

or other reproductive harm.

For more information: www.watts.com/prop65