WAPC250

For parts, product & service information visit www.waynepumps.com

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

Auto On-Off Water Removal

Pool Cover Pump

OPERATING INSTRUCTIONS & PARTS MANUAL

READ, UNDERSTAND AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL - DO NOT DISCARD.

Failure to follow these instructions could result in property damage, serious injury or death.

Risk of electric shock. This pump

has NOT been tested for use in marine

areas. NEVER place pump in pools while people are in the water.

Do NOT handle pump with wet hands or when standing in water

or on a damp surface. Pump is designed to be used in closed and

covered pools only. Water accumulated on pool cover can cause

injury or death. Proper installation of pool cover pump and periodic

maintenance is recommended. Failure to follow COULD result in

death or serious injury.

1. Wear safety glasses at all times when working

with pumps.

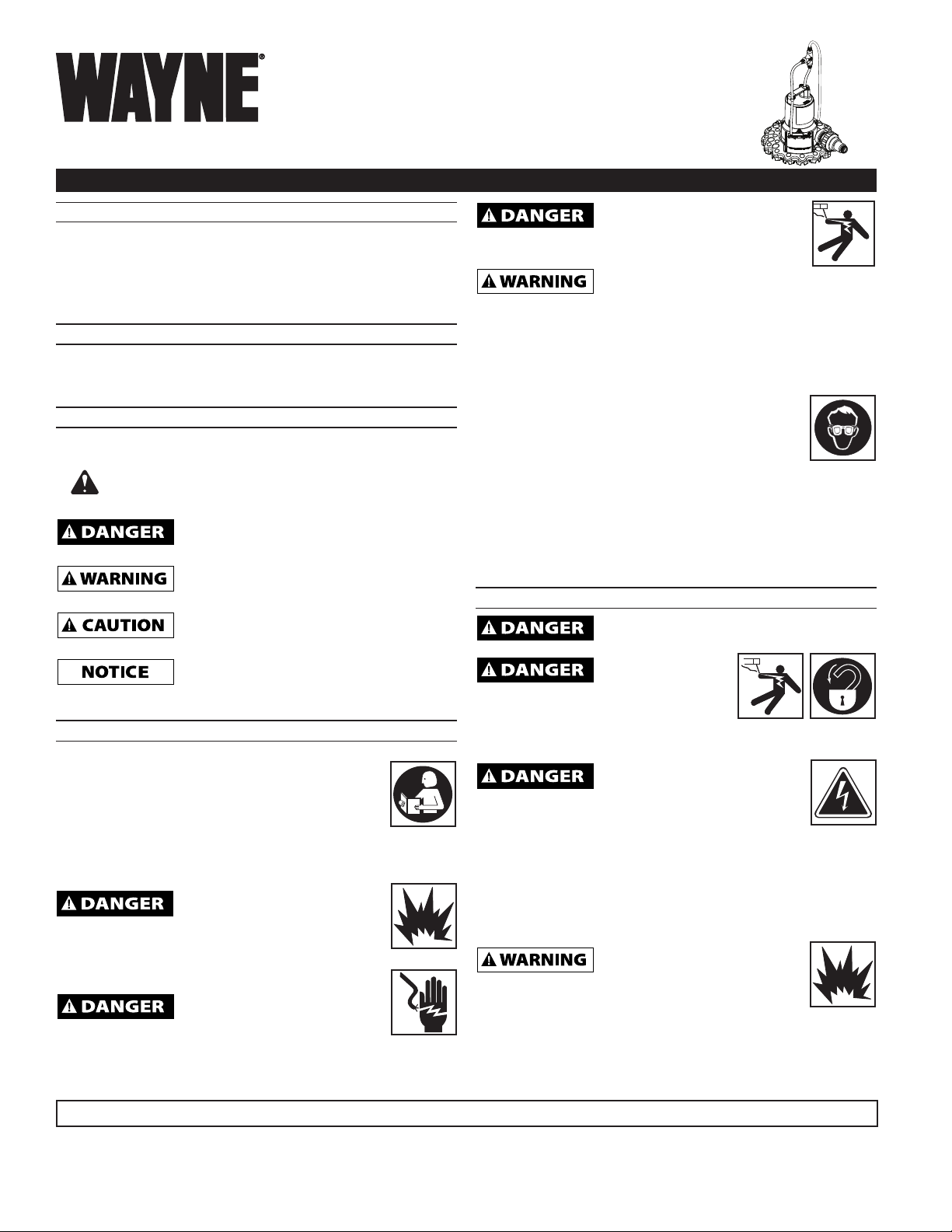

2. The unit MUST be plugged into a properly

grounded GFCI outlet. Consult with a qualified

electrician for proper installation of a GFCI OUTLET.

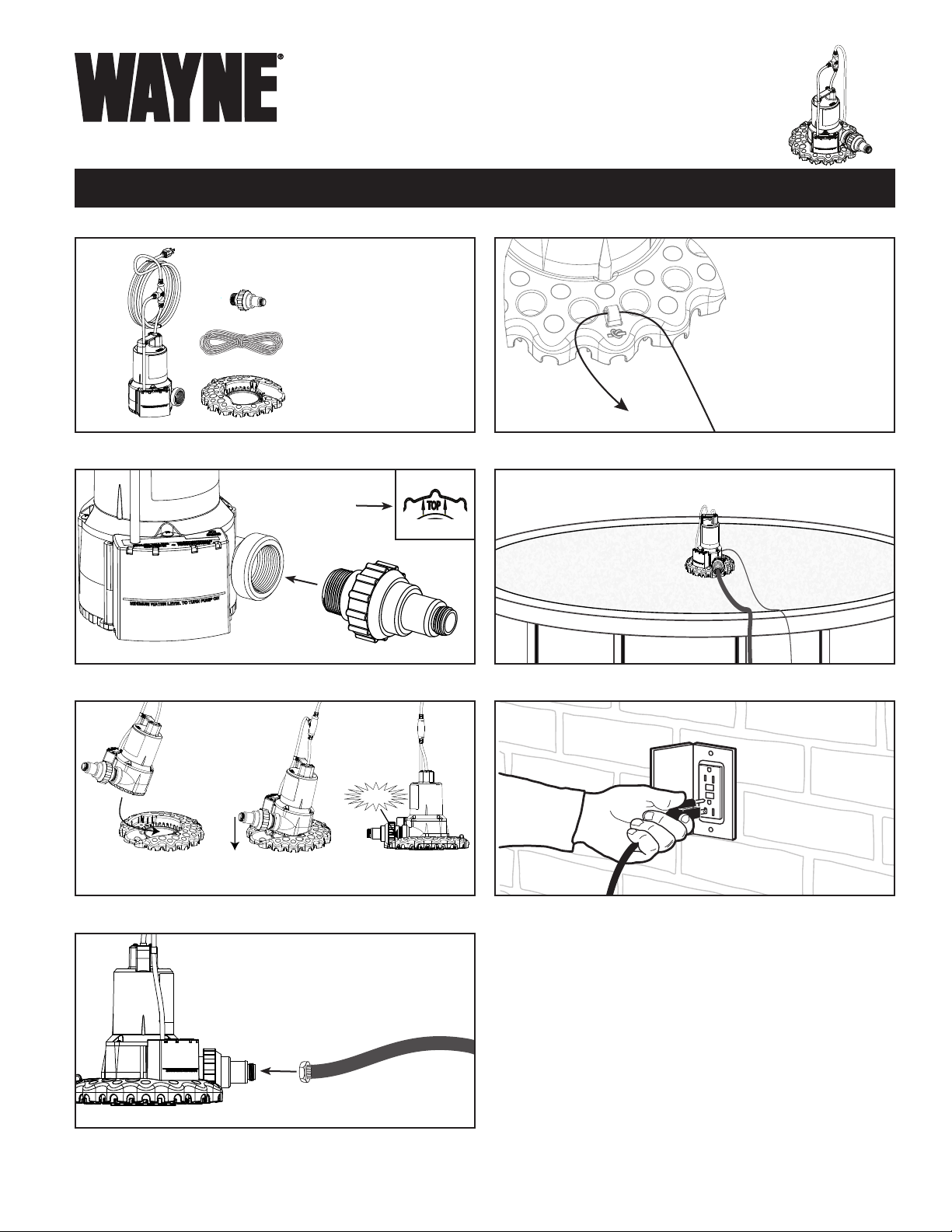

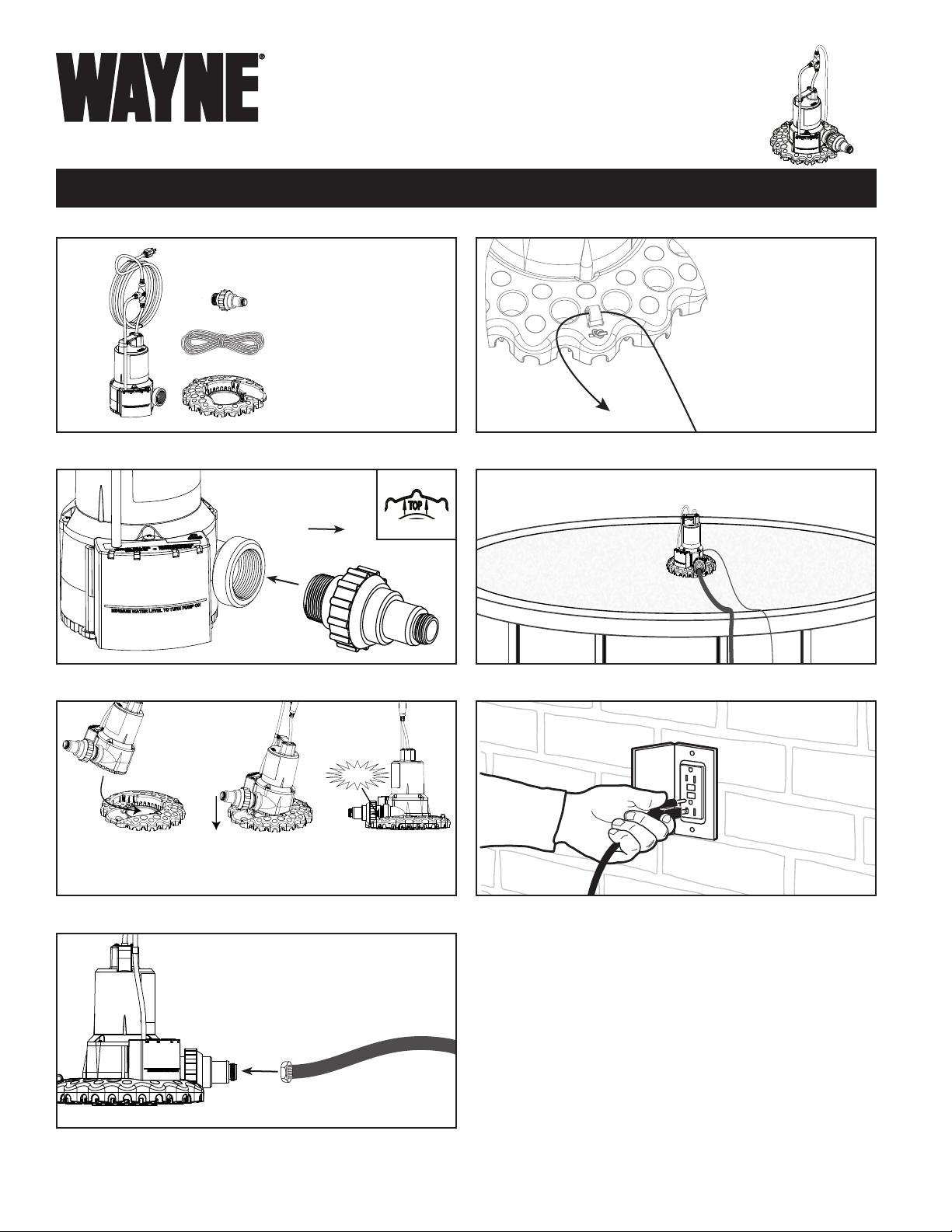

3. DO NOT MOVE, POSITION, RETRIEVE, OR CARRY PUMP

USING THE POWER CORD OR THE DISHCHARGE HOSE,

damage to the pump or power cord may occur. Use the

handle supplied on the pump or attach a string to the strainer

to position as instructed.

APPLICATION AND OPERATION

Do NOT use pump if any part of the housing

switch or probe is cracked, broken, or missing.

Always disconnect

electric supply

before attempting to install, service,

relocate, or perform any maintenance. If

the power source is out of sight, lock and

tag in open (off) position to prevent unexpected power application.

Failure to do so WILL result in fatal electrical shock!

Electric shock hazard. Use only

Underwriters Laboratories

(UL)- listed extension cord with #16 gauge or larger wire

that is labeled for outdoor use. Use polarized grounding

type plugs only. Polarized plugs have one blade slightly

wider than the other and can only be inserted one way into the

outlet. If using an extension cord, do NOT allow pump cord/

extension cord connection to fall into swimming pool or come in

contact with water. Pump/extension cord connection must be kept

dry and away from moisture. Do NOT handle plug connector near

water. Failure to follow these instructions WILL result in death or

serious injury.

This unit is NOT designed for use

as a sump pump or in sump

applications. This unit is NOT designed for use in septic

tanks or underground vaults to pump raw sewage or

effluents. NEVER use in hazardous or explosive locations.

DESCRIPTION

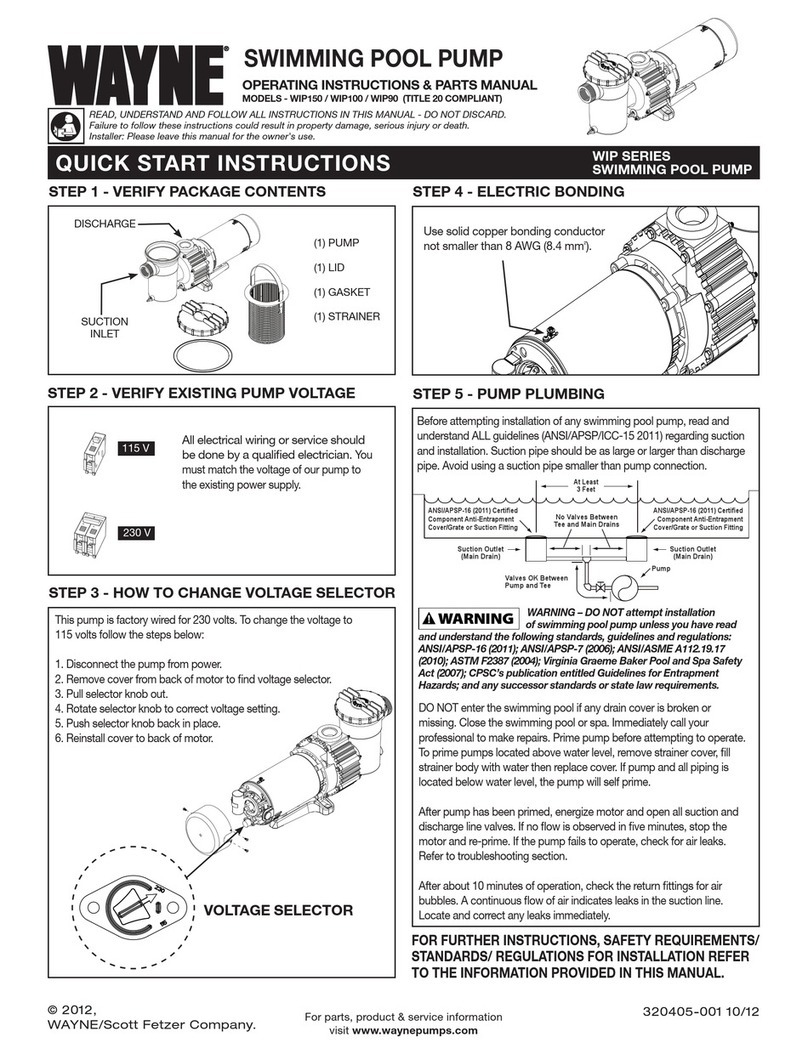

This portable, Auto On-Off Pool Cover pump is designed for

automatic removal of water, from a pool or spa cover. The units

are equipped with a 25 ft. 3-prong grounding type power cord.

The provided discharge check valve prevents short cycling and

it's 3/4 in adapter can be used for convenient attachment to a

standard garden hose.

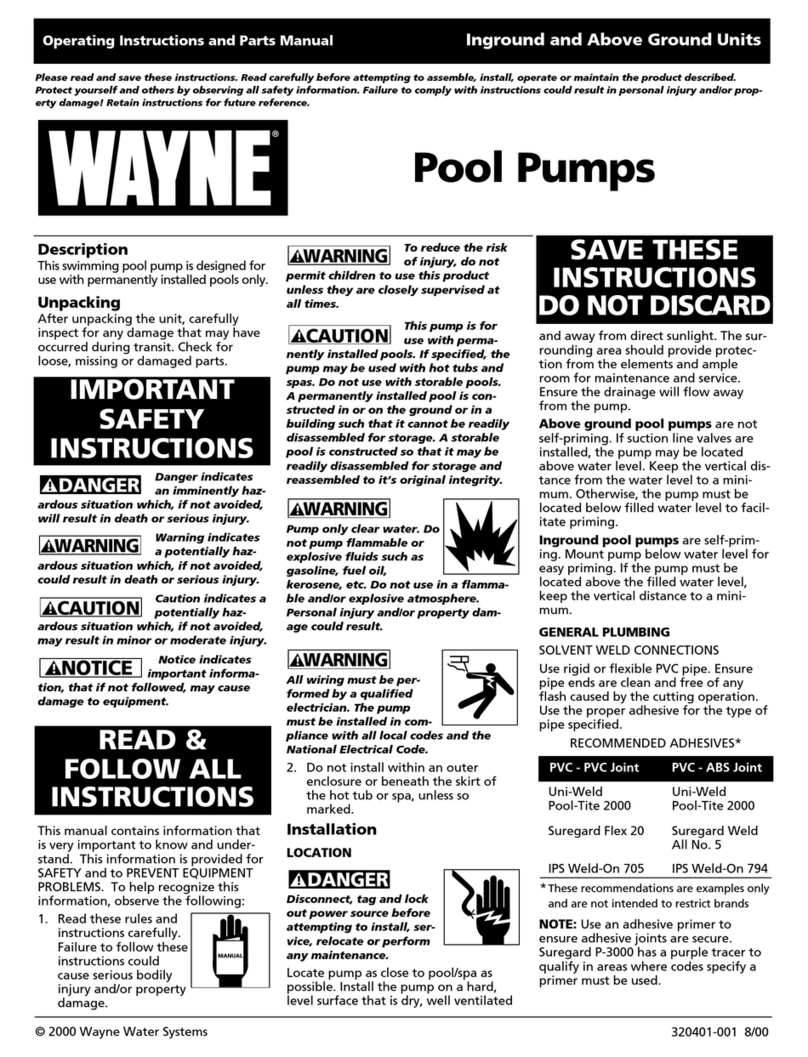

UNPACKING

Inspect this unit before it is used. Occasionally, products are

damaged during shipment. If the pump or components are

damaged, contact customer service at 1-800-237-0987.

SAFETY GUIDELINES

To help recognize this information, observe the following signal

words/hazard classifications.

This is the safety alert symbol. It is used to alert you to

potential bodily injury hazards. Obey all safety messages that

follow this symbol to avoid possible harm.

Danger indicates an imminently hazardous

situation which, if NOT avoided, WILL result

in death or serious injury.

Warning indicates a potentially hazardous

situation which, if NOT avoided, COULD

result in death or serious injury.

Caution indicates a potentially hazardous

situation which, if NOT avoided, MAY result

in minor or moderate injury.

Notice indicates important information, that if

NOT followed, MAY cause damage to equipment.

NOTE:Note indicates information that requires special attention.

GENERAL SAFETY INFORMATION

GENERAL SAFETY

• Readthemanual(s)includedwiththisproduct

carefully. Be thoroughly familiar with the controls

and the proper use of the equipment. Follow all

instructions.

• Onlypersonswellacquaintedwiththeserulesofsafe

operation should be allowed to use the unit. Keep away

from children!

This pump is NOT rated for use

with flammable/combustible

liquids vapors or dusts. Do NOT use to pump flammable/

combustible liquids vapors or dusts. Do NOT use in a

flammable and/or explosive atmosphere. Pump SHOULD

be used to pump clear water ONLY. Failure to follow these

instructions WILL result in bodily injury or death.

Electric shock hazard! GFCI

receptacles will provide protection

against line to ground faults only. The ground fault

receptacle does NOT limit the magnitude of fault current

and will NOT prevent an electrical shock. Replace damaged cord

immediately.

© 2012,

WAYNE/Scott Fetzer Company.

Do NOT disassemble or alter this

product in any way. Failure to

follow these instructions WILL result in serious injury or

death.

2