Accessories FLC210

– 139-2406 shield ES

– 139-2407 shield ET

– 139-2404 IO-180

– 139-2405 IW FLC210

Tools required

– Screwdriver TX20 / TX25

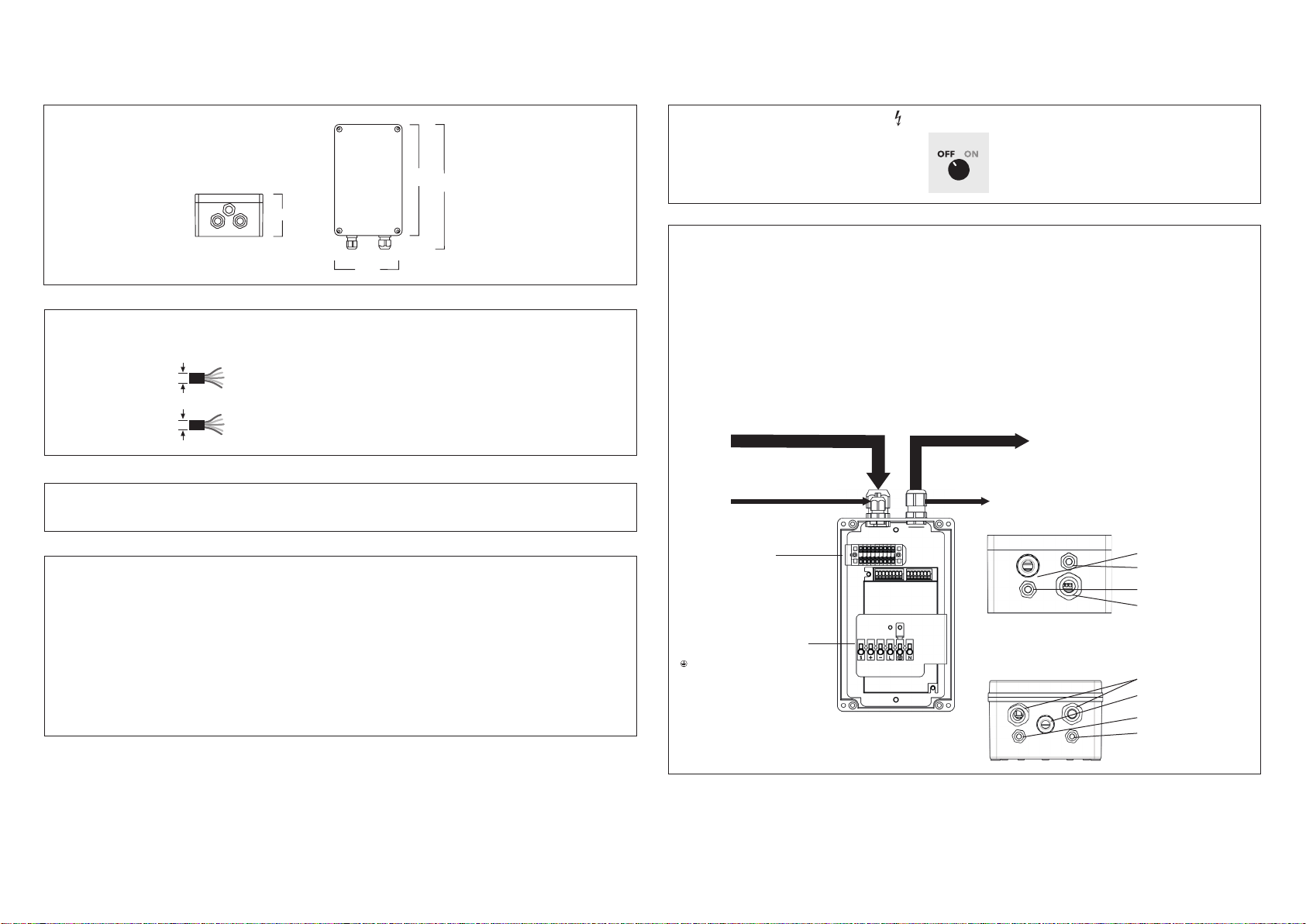

Driver boxes for operating the FLC210 / FLC210 PP

– 139-6978 Sep. Driver Box FLC210 TW

– 139-6979 Sep. Driver Box FLC210 CC

(Also available for through-wiring as an option)

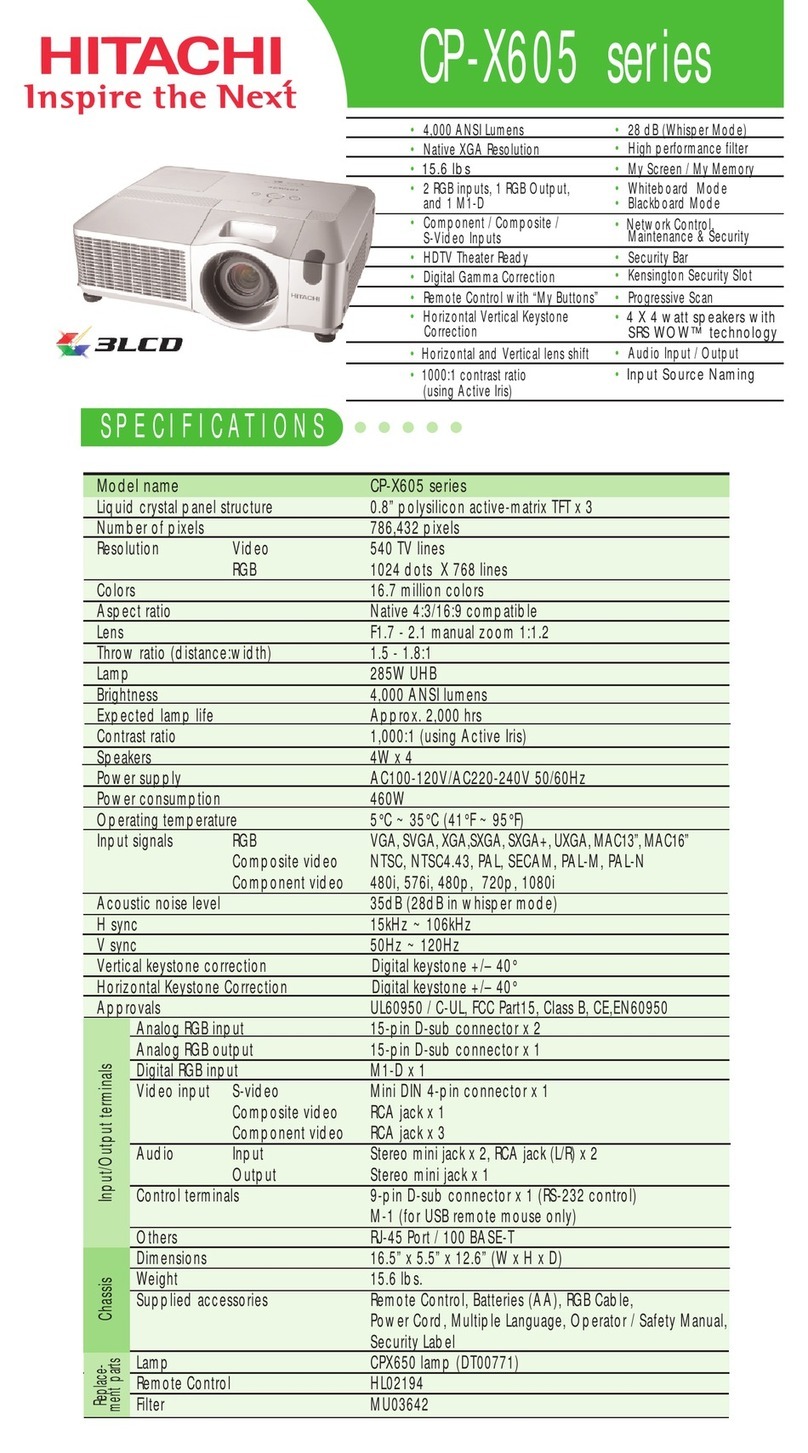

5.91

1.73

FLC210 PP / FLC210 PP CC/TWFLC210 / FLC210 TW/CC

3.94

5.91

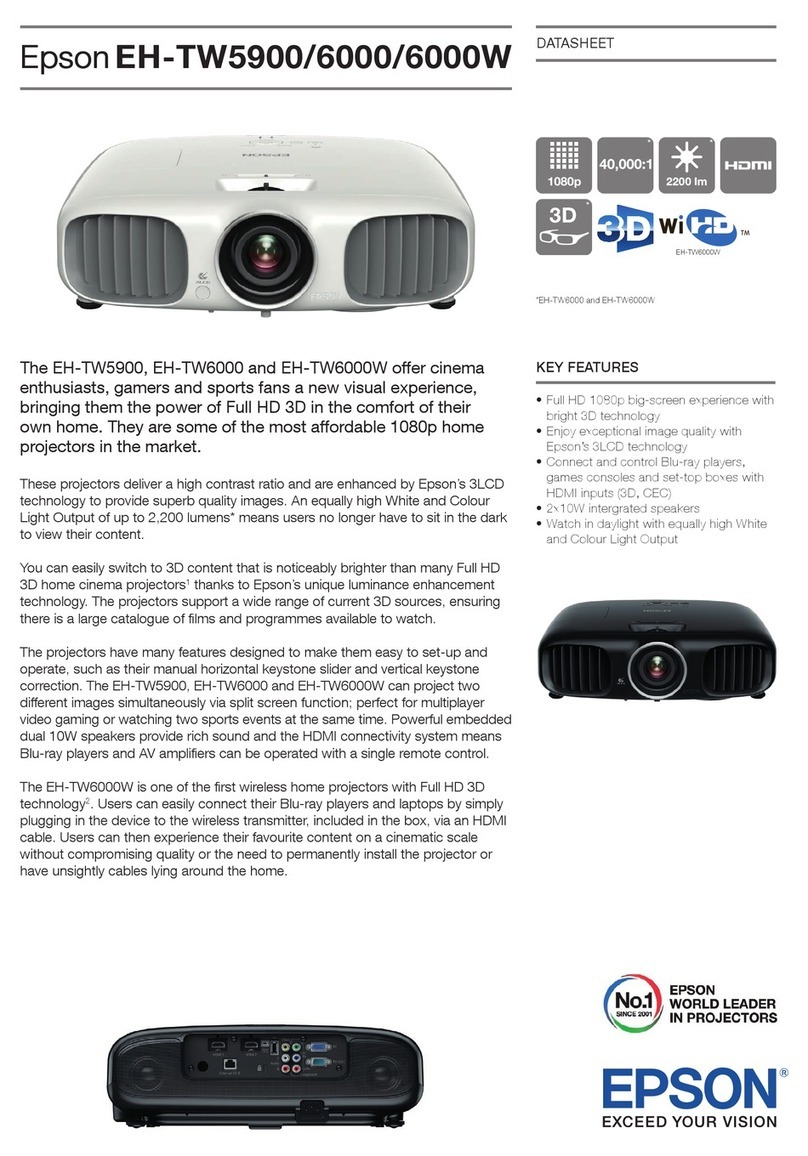

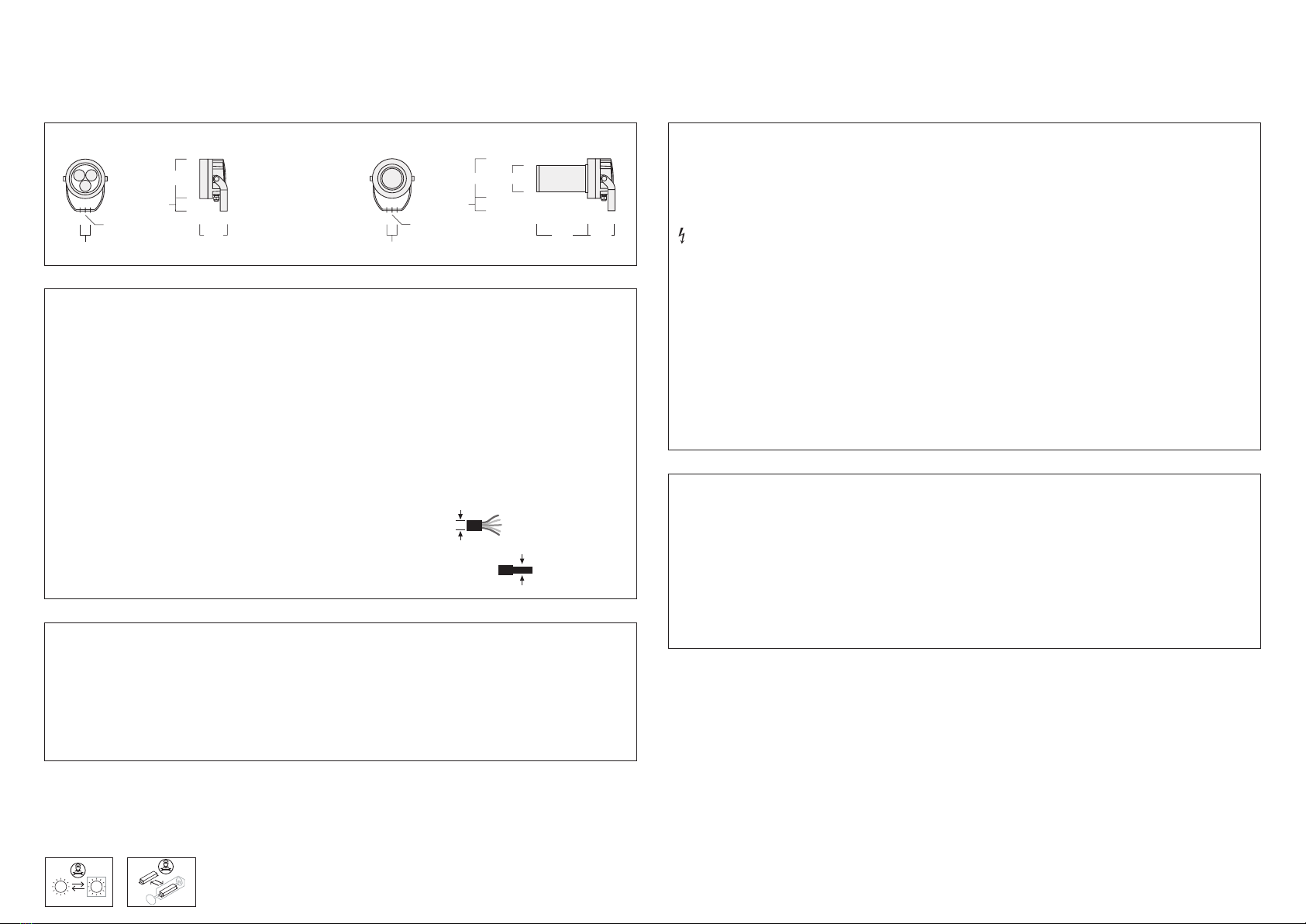

Projectors

IP66, IK07

FLC210: 16 AWG

FLC210 CC/TW: 16 AWG

ø 0.177 – 0.394 in

Light source

FLC210 .................. 3 LED 6W / 9W / 12W

FLC210 PP ........................ 18W / 26W

TW and CC luminaires are always with a driver box /

operating device. For information and luminaire

connection, see the attached connection/wiring

diagram.

FLC210-TW ........................ 3 LED 11W

FLC210 PP-TW ........................... 10W

FLC210-CC .........................3 LED 12W

FLC210 PP-CC ........................... 15W

FLC210 .......................Class I, ta=25 °C

FLC210-TW ....................Class I, ta=25 °C

FLC210-CC ............................Class III

Windage area

FLC210 .............................. 0.194 ft²

FLC210 PP ........................... 0.377 ft²

Weight

FLC210 ............................max. 6.6 lb

FLC210 PP .........................max. 8.8 lb

120-

277 V

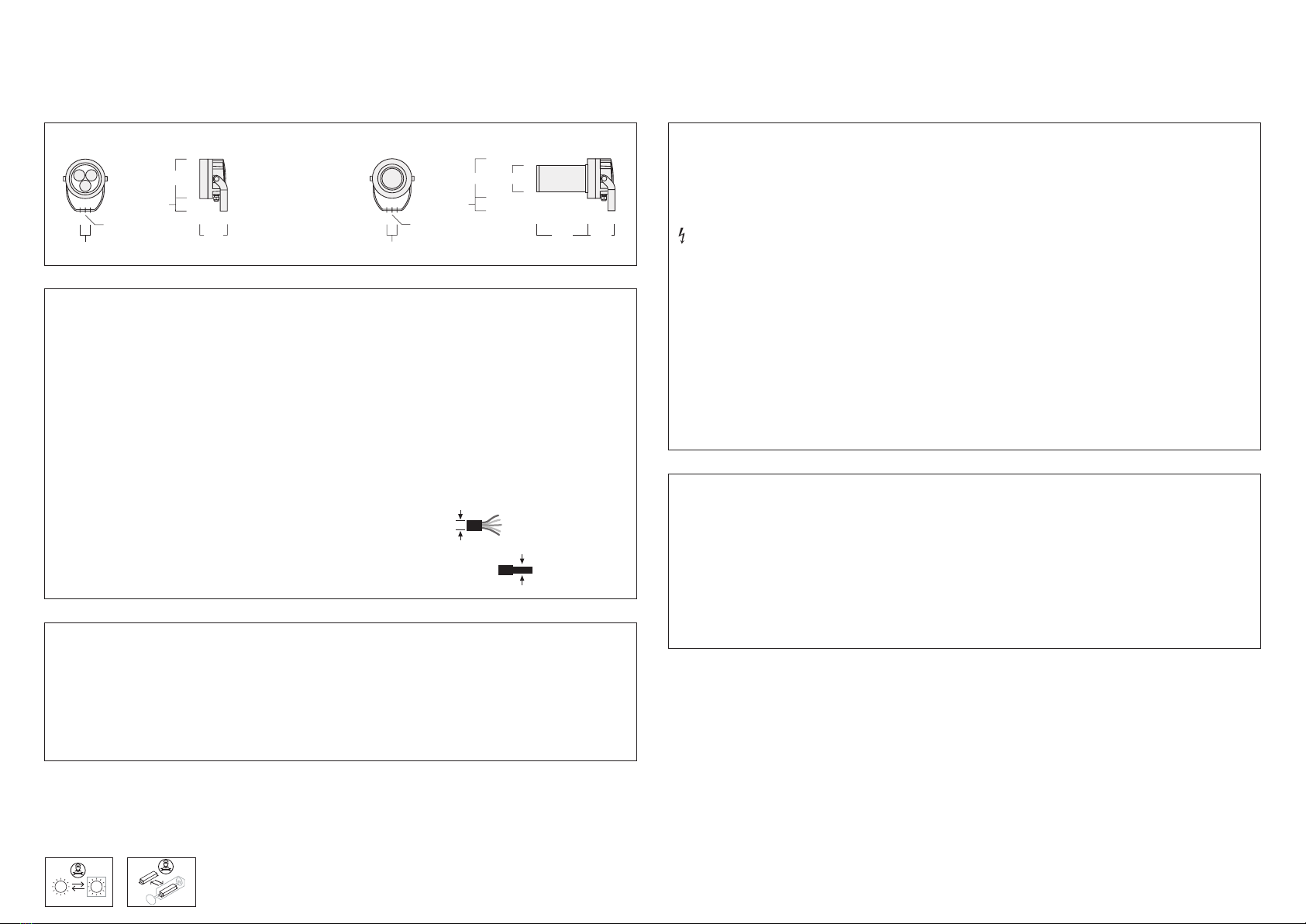

Installation

The product must be installed and maintained by

a suitably qualified professional in compliance with

latest building/construction and/or electrical regu-

lations and relevant legislation.

Attention: Switch off mains electrical supply prior

to installing and connecting the luminaire. Do not

open luminaire while mains supply is switched on.

Notice: If the luminaire is modified by anybody

other than the original manufacturer, then the

warranty will no longer be valid and shall become

the full responsibility of the modifying person/

organisation. Claims based on defects attributable

to improper installation and/or application, and the

consequences thereof, are excluded.

In case of component failure, LED replacement

due to abnormal circumstances or at end of life,

replacement must be carried out by a suitably qua-

lified and trained professional.

In case of questions please contact our technical

hotline: +1 724 742 0030 (from Monday - Friday

from 08.00 until 16.00 hours).

Maintenance

Apart from cleaning the product’s exterior surfaces,

no special maintenance work is required. Do not

use high-pressure cleaners.

Protect our environment: Discard used LEDs in

compliance with the most recent environmental

legislation.

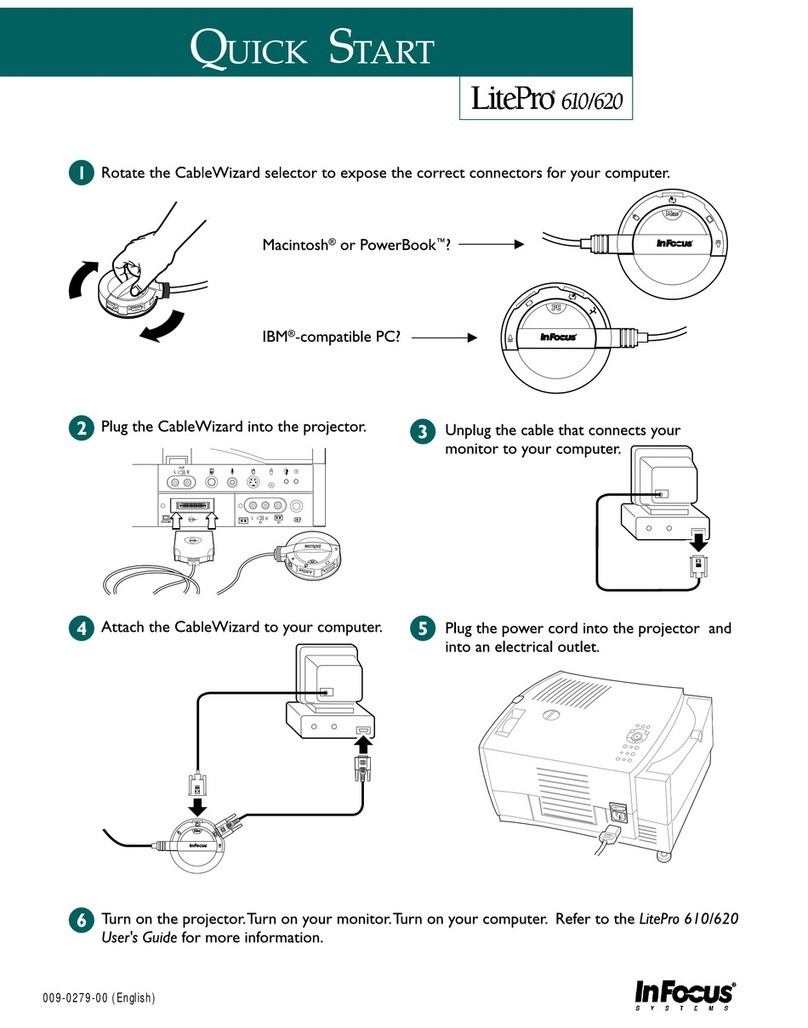

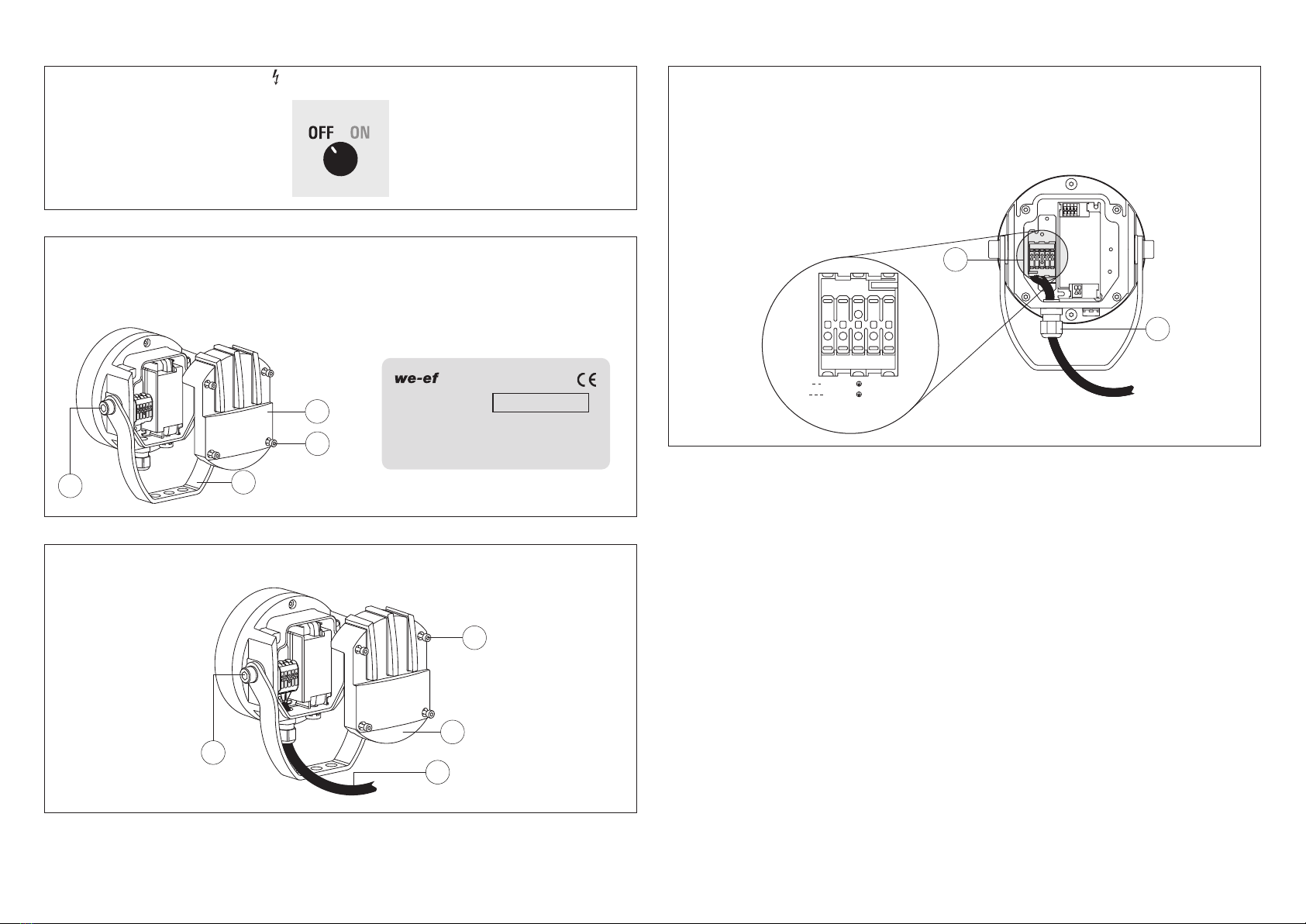

Installation Procedure

1) Prior to electrical connection, proceed with

mechanical installation by firmly fixing stirrup A

to optional mounting accessory or directly to a

suitable surface. Aim luminaire.

ATTENTION: Make sure not to damage any

electric cable, water pipe or other devices while

drilling holes.