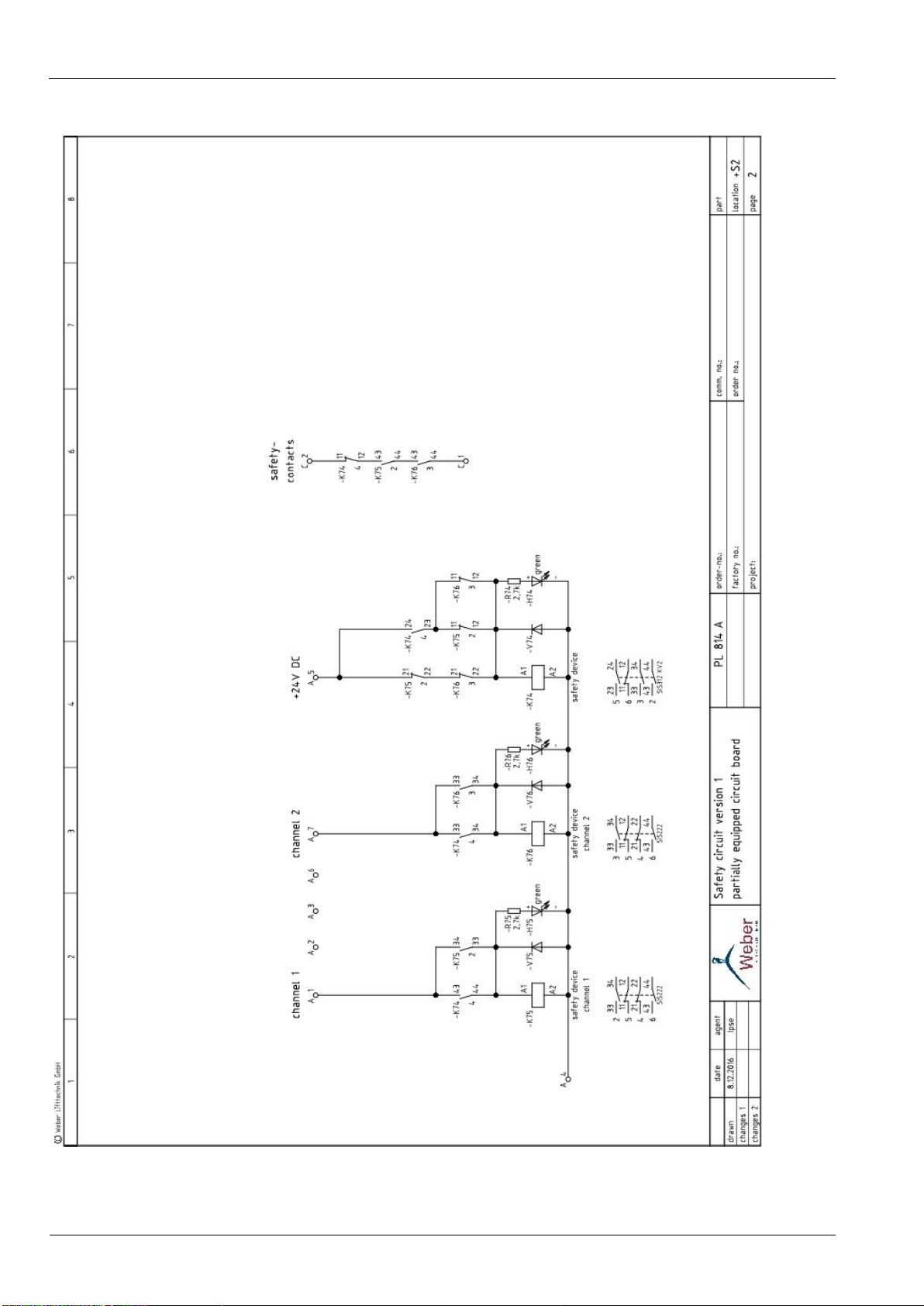

3.3. Safety device PL814 version 2 for approach and re-adjustment with open doors

See circuit diagram: “6.3. Safety device PL814 version 2”

See circuit diagram: “7.2. Shaft copying”

See function description of the safety device: “3.1. Safety device version 1”

If approach or readjustment should be possible with open doors, the completely equipped

circuit board PL814 bridges the door switch and the switch for the locking mechanism in the lift

control units by Weber Lifttechnik GmbH.

The relay –K73 (connection terminal A2) is activated via a control unit output as soon as the

control unit and the absolute encoder for the shaft copying system are ready for operation. It

remains energised as long as operational readiness remains. A contact for this relay prevents

the safety relay of the second channel –K76 being activated, as long as the control unit and

therefore the input signal for the first channel –K75 are not ready for operation. The second

contact is available potential-free, for example, in order to activate the UCM-monitoring circuit

board PL751A only after achieving readiness for operation.

A further control unit output supplies an enable signal for the relay -K60, if the following

conditions are fulfilled:

a. The approach or readjustment procedure should be executed.

b. The travel speed has the permitted values (slow, under 0.3 m/s) as in EN81, for

approach and readjustment procedures.

In case of hydraulic lifts or unregulated traction elevators without impulse generators for

position recording, a speed measurement is not possible. The enable then occurs after

switching to slow speed.

If the conditions for the relay –K60 are fulfilled, on reaching the door zone configured on the

control unit the safety relay -K75 (channel 1) is activated via the control unit output “Readjust

(door zone)”. –K75 remains energised, as long as the lift car is positioned within the door zone.

This door zone signal is provided by a transducer, e.g. absolute encoder or magnetic or

electronic adjustment switches which are connected to the control computer.

The second safety relay -K76 (channel 2) is activated directly via a switch in the door zone,

e.g. magnetic switch. It energises as soon as the door zone switched is actuated and the

abovementioned enable relays -K60 and –K73 are energised. It then remains switched on until

the lift leaves the door zone again.

As soon as the two relays -K75 and -K76 are energised, -K74 is de-energised. As a result, the

shunt circuit of the door switch and the switch of the locking mechanism between the

connection terminals C1 and C2 are closed and the door may open.

As soon as the lift leaves the door zone, the two relays -K75 and -K76 de-energise and -K74

can energise. Should -K74 not energise, then the two relays -K75 and -K76 remain de-

energised on approaching the target stop, and therefore the bridging of the door switch and

the switch for the locking mechanism are opened.