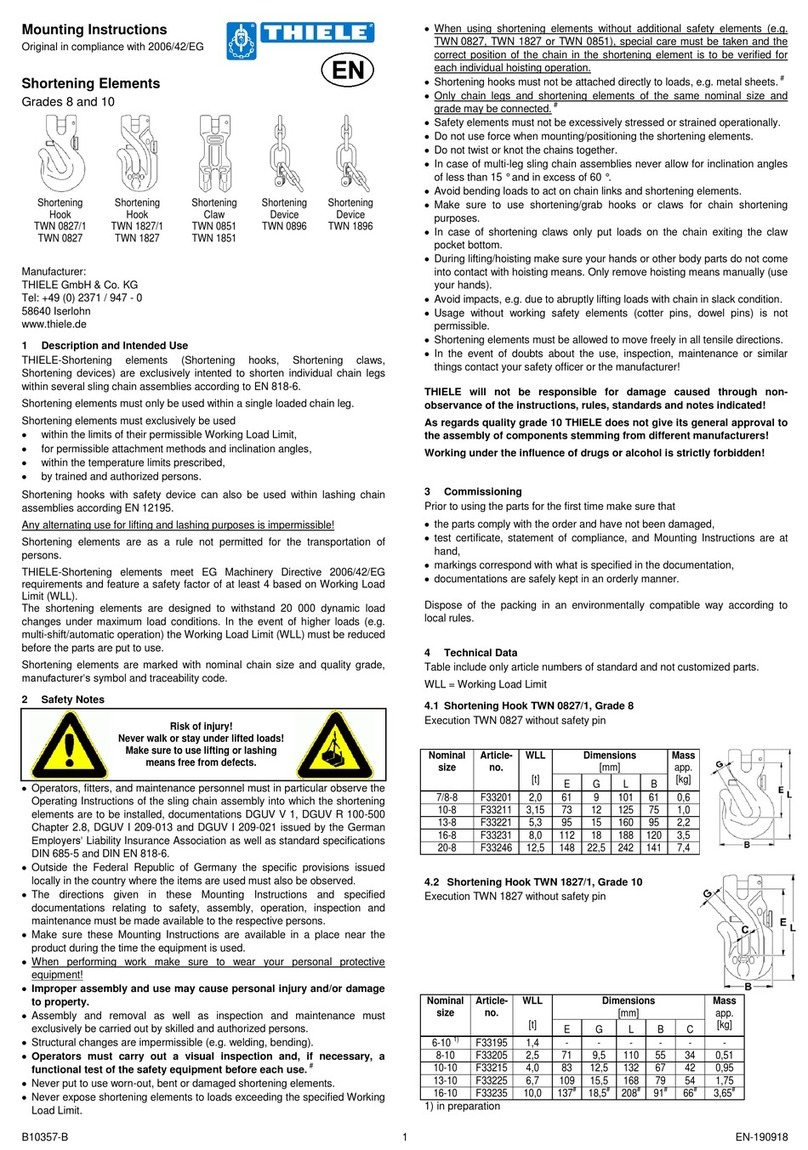

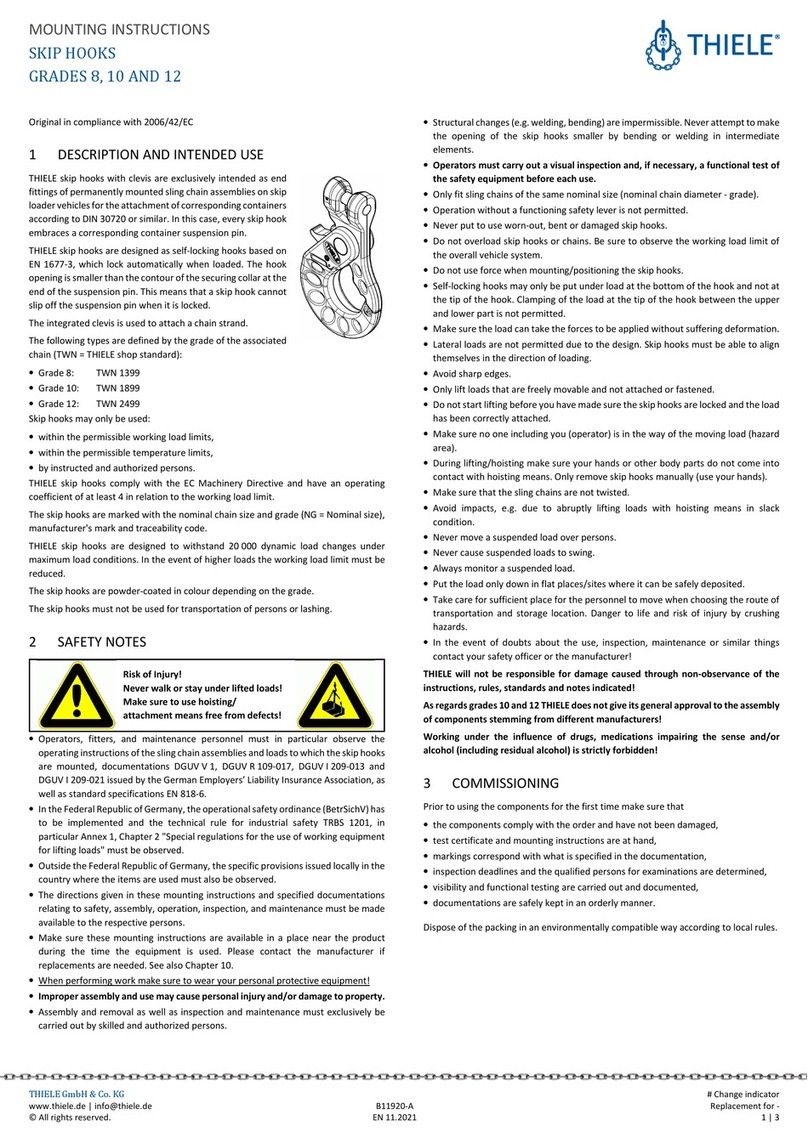

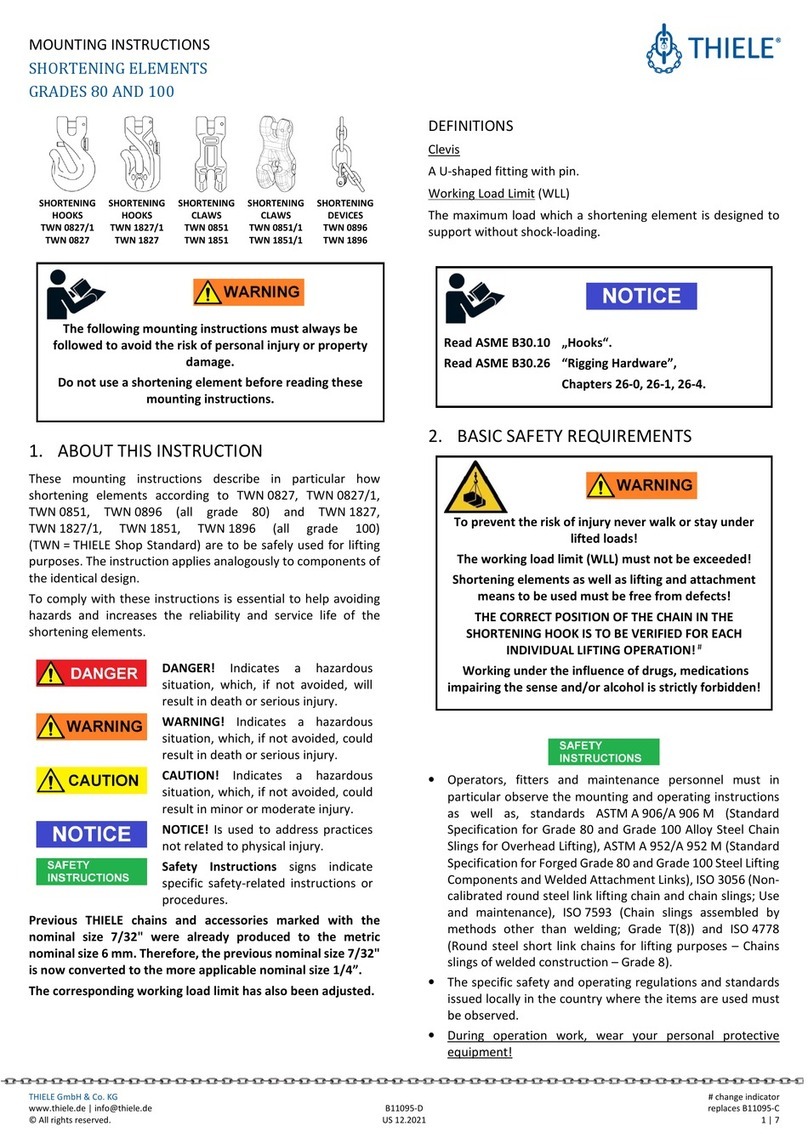

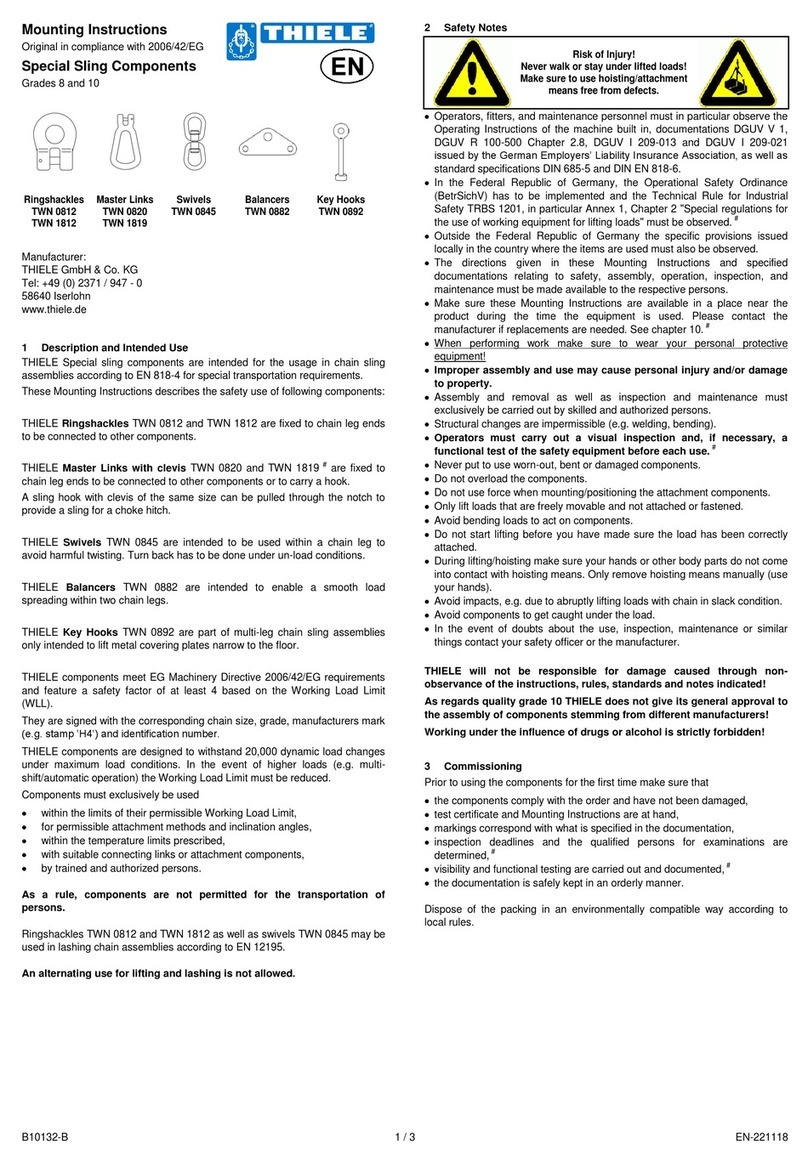

MOUNTING INSTRUCTIONS

PIPE TRANSPORT HOOKS TWN 0868

THIELE GmbH & Co. KG # Change indicator

© All rights reserved EN 07.2020 1 | 2

DESCRIPTION AND INTENDED USE

THIELE-Pipe transport hooks are intended for the use in 2-leg chain slings of grade 8

and are used for the safe transport of pipes.

These mounting instructions describe in particular the safe use of THIELE-Pipe

transport hooks according to TWN 0868 (TWN = THIELE factory standard).

The chain slings with pipe transport hooks may only be used:

•if mass and center of gravity of the load are known,

•within the limits of their permissible Working Load Limit,

•within the limits of the permissible inclination angles,

•within the temperature limits prescribed,

•for the transport of pipes with symmetrical load,

•with suitable connecting links, chain slings and suspension links,

•by trained and authorized persons.

THIELE-Pipe transport hooks meet EG Machinery Directive 2006/42/EG

requirements and feature a safety factor of at least 4 based on the Working Load

Limit. They are certified by the German Employer's Liability Insurance Association

Wood and Metal and signed with the corresponding chain size, grade, manufacturers

mark (H4) and traceability code.

They are designed to withstand 20,000 dynamic load changes under maximum load

conditions. In the event of higher loads (e.g. multi-shift) the Working Load Limit must

be reduced.

As a rule, pipe transport hooks are not permitted for the transportation of persons.

SAFETY NOTES

•Operators, fitters, and maintenance personnel must in particular observe the

Operating Instructions of the used chain sling, documentations DGUV V 1, DGUV

R 100-500 Chapter 2.8, DGUV I 209-013 and DGUV I 209-021 issued by the German

Employers’ Liability Insurance Association, as well as standard specifications DIN

685-5, EN 818-4 and EN 818-6.

•Outside the Federal Republic of Germany the specific provisions issued locally in

the country where the items are used must also be observed.

•The directions given in these Mounting Instructions and specified documentations

relating to safety, assembly, operation, inspection, and maintenance must be

made available to the respective persons.

•Make sure these Mounting Instructions are available in a place near the product

during the time the equipment is used.

•When performing work make sure to wear your personal protective equipment!

•Improper assembly and use may cause personal injury and/or damage to

property.

•Assembly and removal as well as inspection and maintenance must exclusively be

carried out by skilled and authorized persons.

•Structural changes are impermissible (e.g. welding, bending).

•Operators must carry out a visual inspection and, if necessary, a functional test

of the safety equipment before each use.

•Pipe transport hooks may only be used in pairs.

•Never put to use worn-out, bent or damaged pipe transport hooks.

•Only lift loads the mass of which is less than or equal to the Working Load Limit of

the chain sling.

•Never expose pipe transport hooks or corresponding chain slings to loads

exceeding the specified Working Load Limits.

•Do not use pipe transport hooks under high dynamic and cyclical loads (e.g. multi-

shift operation).

•For chain slings with pipe transport hooks, inclination angles between 15° and 45°

are only permissible.

•Suspension links must be allowed to move freely in the crane hook.

•Connecting links must be able to move freely in the eye of the pipe transport hook.

•Do not tip-load a pipe transport hook.

•Do not use force when mounting/positioning pipe transport hooks.

•Check that the pipe can absorb the forces to be applied without deformation.

•Asymmetrical loads are not permitted, therefore shortening of chain legs must be

avoided.

•When using pipe transport hooks special care must be taken and a special risk

assessment should be done.

•Do not start lifting before you have made sure the load has been correctly

attached.

•Make sure that adjacent pipes of the pipe to be lifted are secured against

unintentional moving.

•When lifting a pipe, the adjacent pipes must not be touched. Use guide ropes if

necessary.

•Make sure no one includingyou (operator) is in the way of the moving load (hazard

area).

•During lifting/hoisting make sure your hands or other body parts do not come into

touch with hoisting means. Only remove hoisting means manually (by hands).

•Avoid impacts, e.g. due to abruptly lifting loads with chain in slack condition.

•Never move a suspended load over persons.

•Never cause suspended loads to swing.

•Make sure that the chains are not twisted.

•Always monitor a suspended load.

•Put the load only down in flat places/sites where it can be safely deposited.

•Avoid parts of the chain sling to get caught under the load.

•Take care for sufficient place for the personnel to move when choosing the route

of transportation and storage location. Danger to life and risk of injury by crushing

hazards!

•Pipes to be lowered must be secured against unintentional moving.

•In the event of doubts about the use, inspection, maintenance or similar things

contact your safety officer or the manufacturer.

THIELE will not be responsible for damage caused through non-observance of the

instructions, rules, standards and notes indicated!

Working under the influence of drugs and alcohol consumption (including residual

alcohol) as well as drugs affecting the senses is strictly prohibited.

COMMISSIONING

Prior to using the components for the first time make sure that

•the components comply with the order and have not been damaged,

•test certificate and Mounting Instructions are at hand,

•markings correspond with what is specified in the documentation,

•inspection deadlines and the qualified persons for examinations are

determined,

•visibility and functional testing are carried out and documented,

•the documentation is safely kept in an orderly manner.

Dispose of the packing in an environmentally compatible way according to local

rules.