980230 –RCV190 Manual Page 2 of 25

Rev 6 Issue 3. Date: 18/09/23

Table of Contents

1Important Notice –Read Before Use................................................................................... 3

2Introduction....................................................................................................................... 3

3Technical Data.................................................................................................................... 4

3.1 Physical......................................................................................................................................... 4

3.2 Hydraulic Requirements............................................................................................................... 4

3.3 Environmental Considerations ..................................................................................................... 4

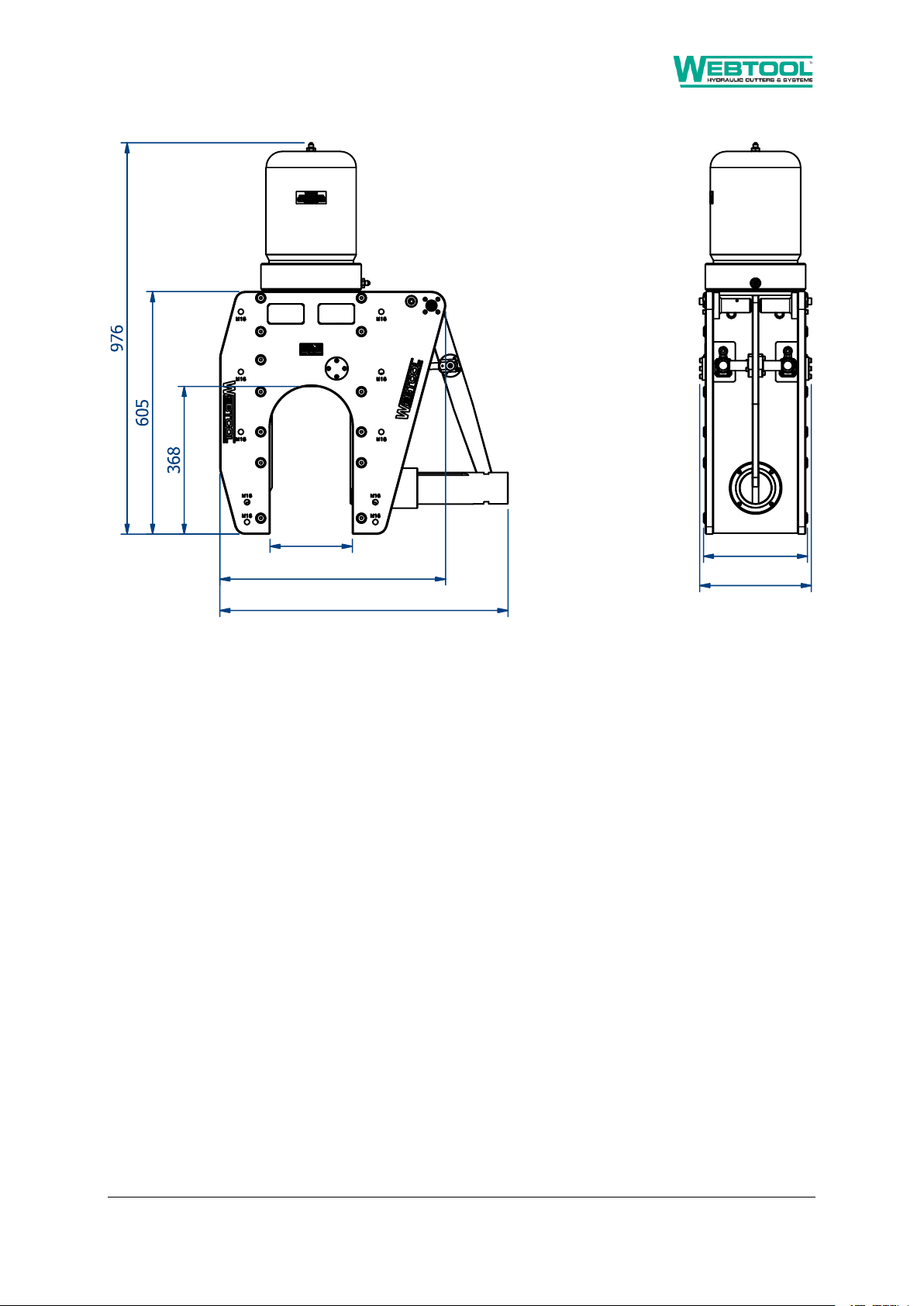

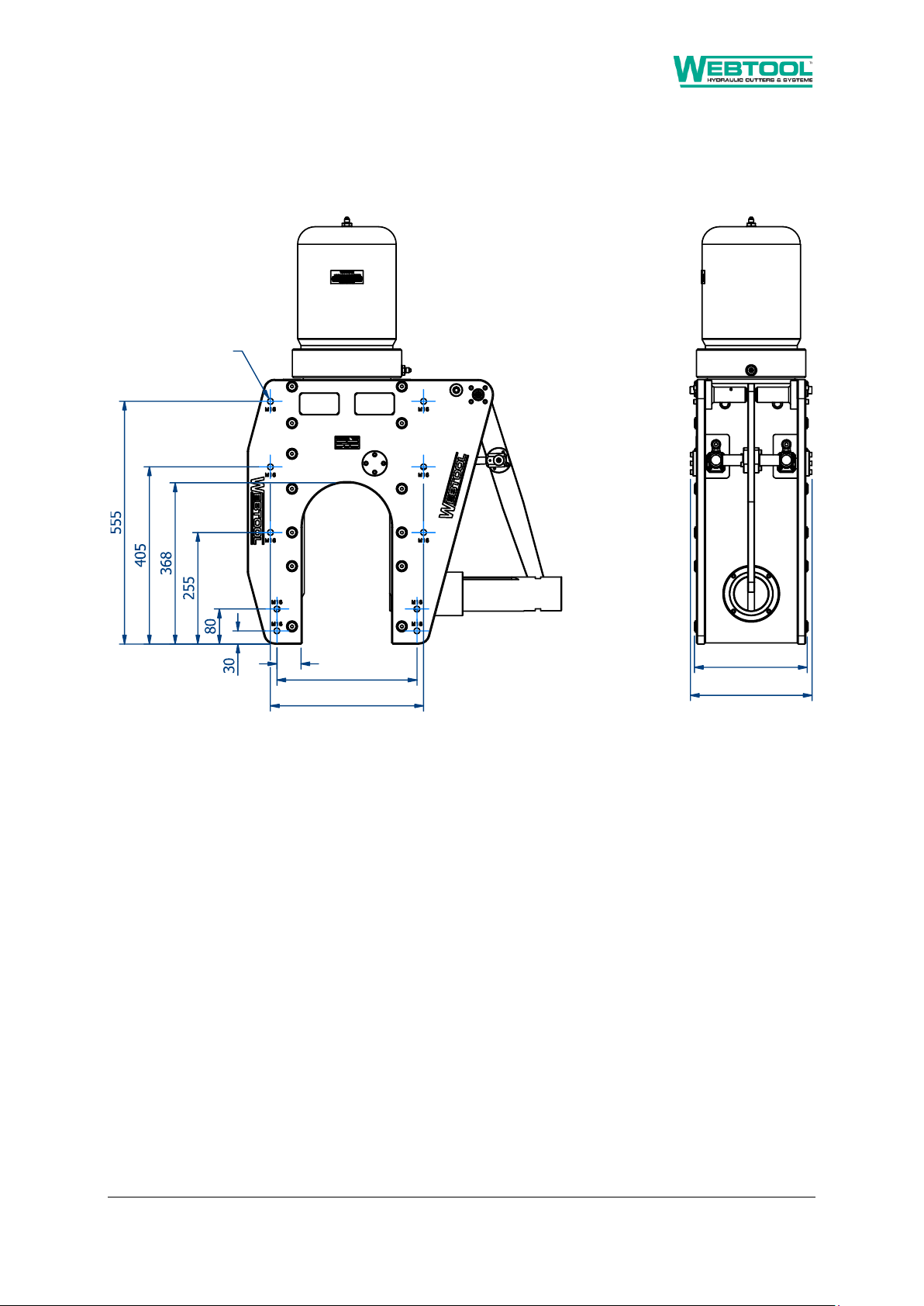

3.4 Dimensions................................................................................................................................... 5

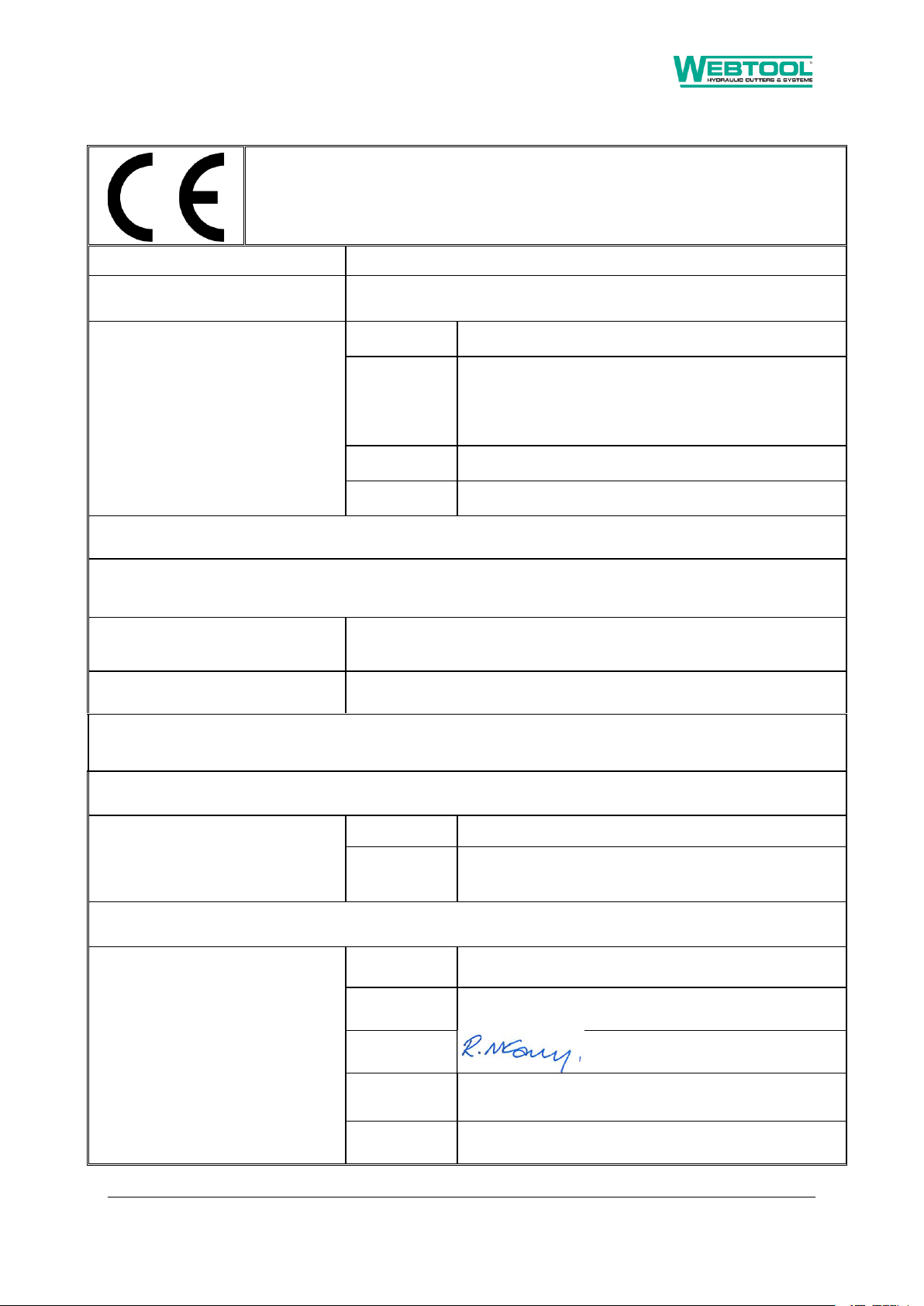

4Declaration of Incorporation............................................................................................... 6

5General Safety Rules .......................................................................................................... 7

5.1 Warnings....................................................................................................................................... 7

5.2 Important Information ................................................................................................................. 7

5.3 Safety for Operation..................................................................................................................... 7

5.4 Safety for Maintenance................................................................................................................ 8

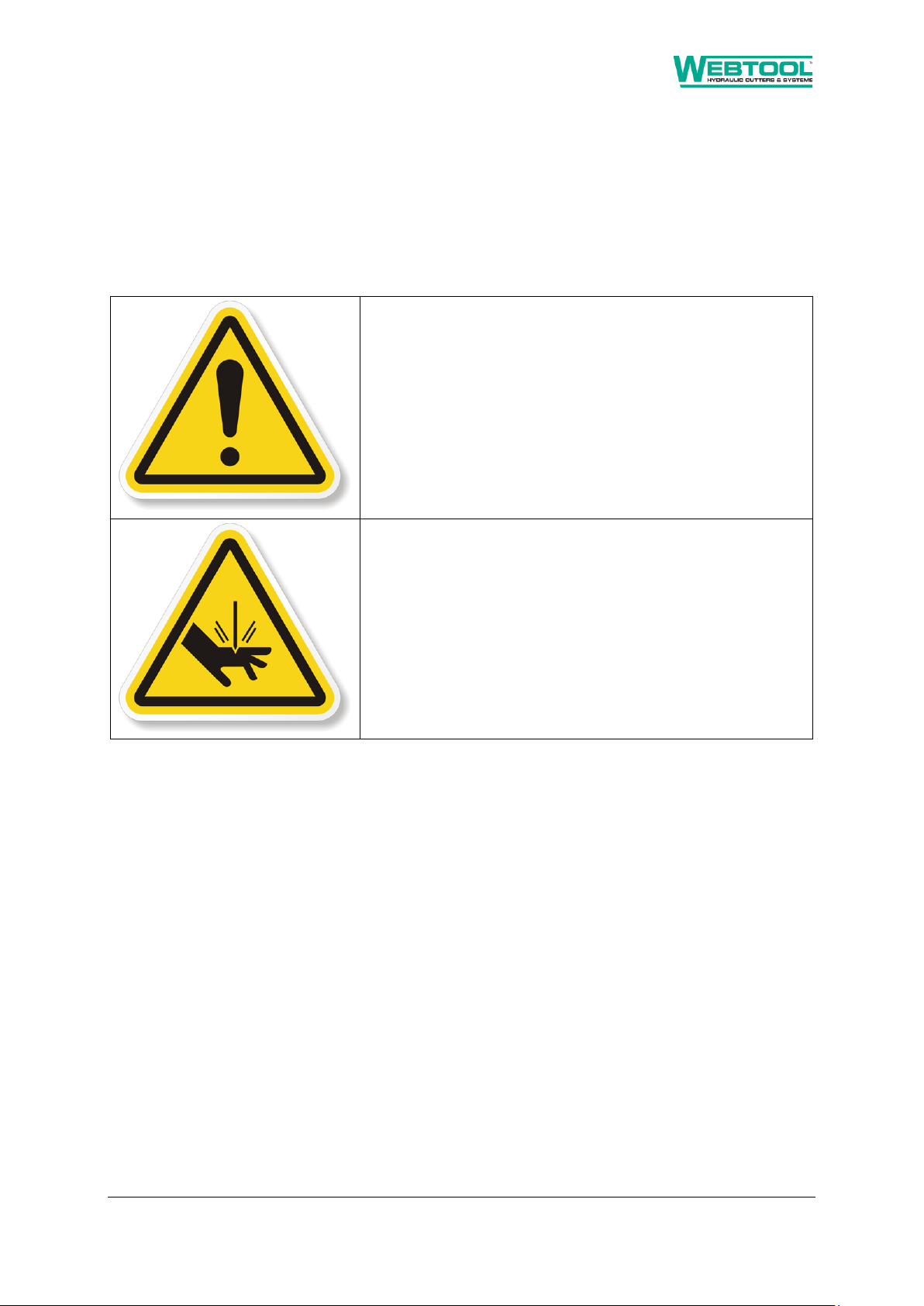

5.5 Warning Symbols.......................................................................................................................... 8

6Installation......................................................................................................................... 9

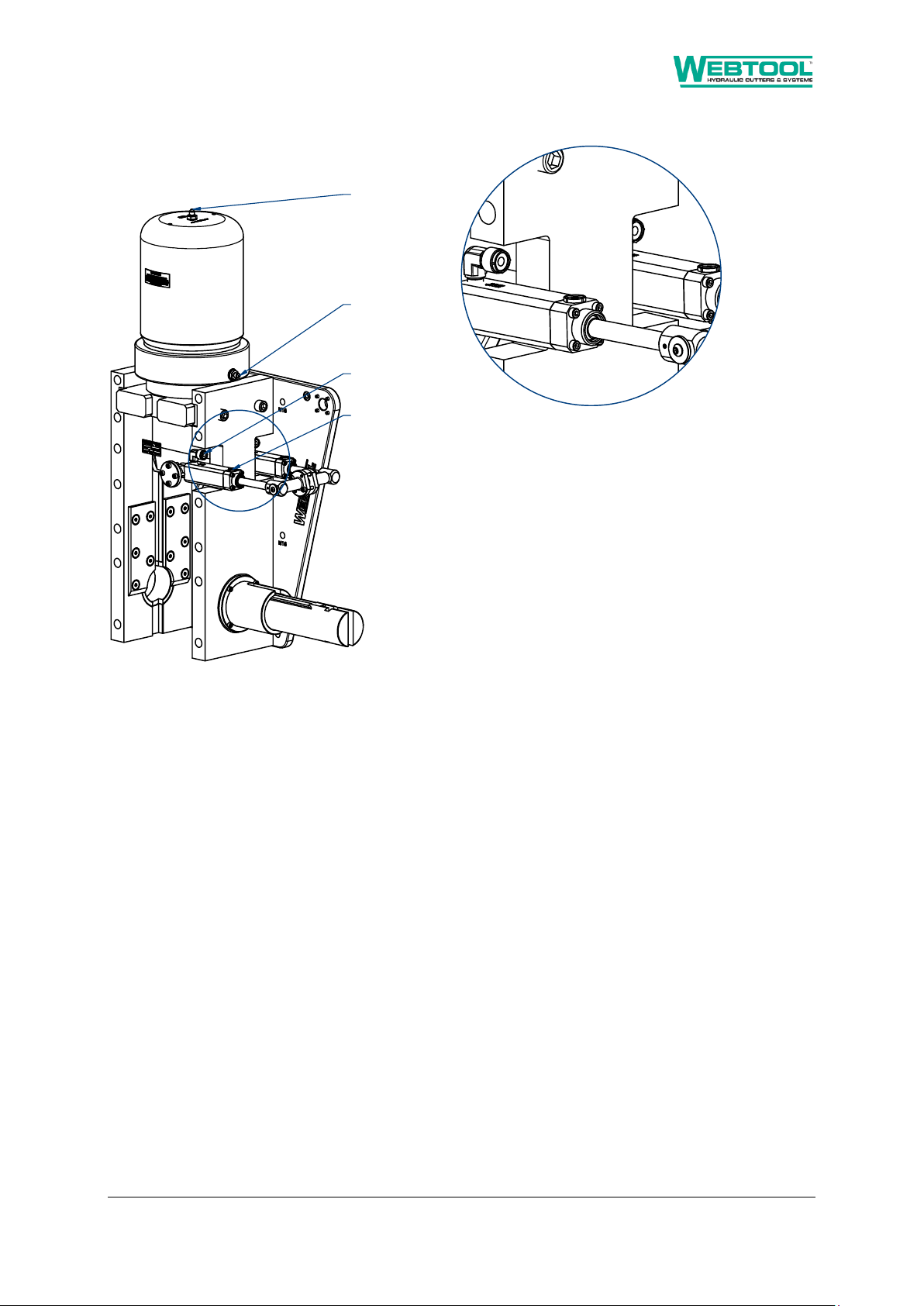

6.1 Mounting Holes............................................................................................................................ 9

7Hydraulic Connections...................................................................................................... 10

8Operating Instructions...................................................................................................... 11

8.1 Before Use.................................................................................................................................. 11

8.2 Deploying the Tool ..................................................................................................................... 11

8.3 Pre-Cut Check............................................................................................................................. 12

8.4 Extend the Blade (Cut Cycle) ...................................................................................................... 12

8.5 Retract the Blade (Return Cycle) ................................................................................................ 12

9Maintenance.................................................................................................................... 13

9.1 Maintenance Notes.................................................................................................................... 13

9.2 Maintenance Schedule............................................................................................................... 13

9.3 Remove & Replace Anvil............................................................................................................. 14

9.4 Remove & Replace Blade............................................................................................................ 17

9.5 Seal Detail................................................................................................................................... 19

10 Parts List.......................................................................................................................... 22

11 Decommissioning............................................................................................................. 23