2

Contents

1. Application Notices........................................................................................................................................... 3

1.1. About the User Manual..............................................................................................................................3

1.2. Safety Precautions..................................................................................................................................... 3

1.3. Printing Consumables................................................................................................................................ 3

1.4. Environment requirements........................................................................................................................4

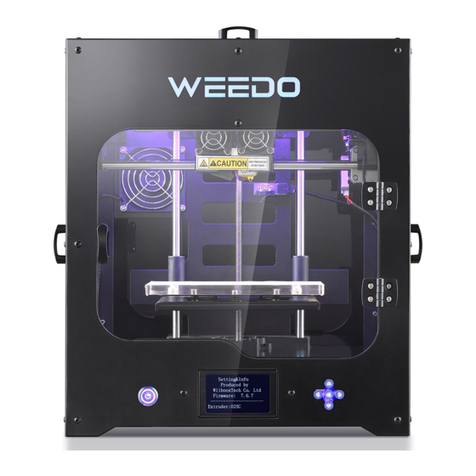

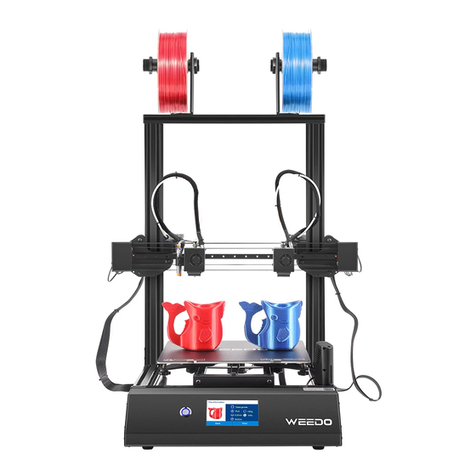

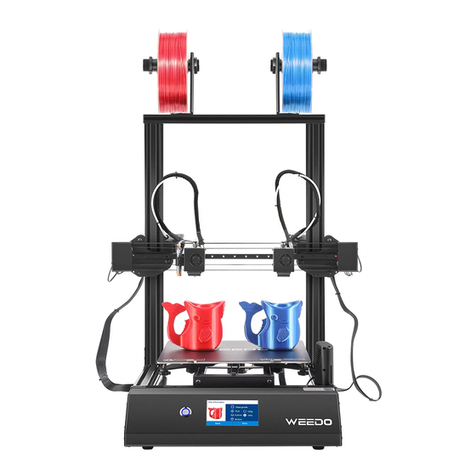

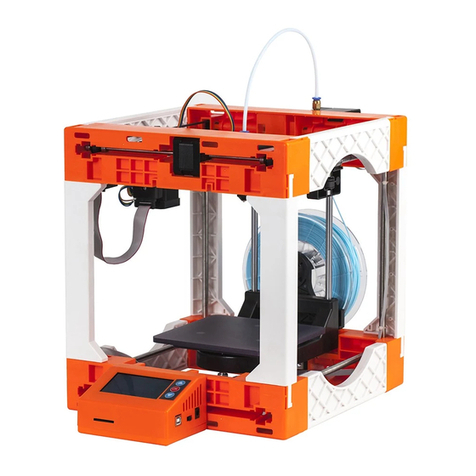

2. Introduction to the Printer................................................................................................................................4

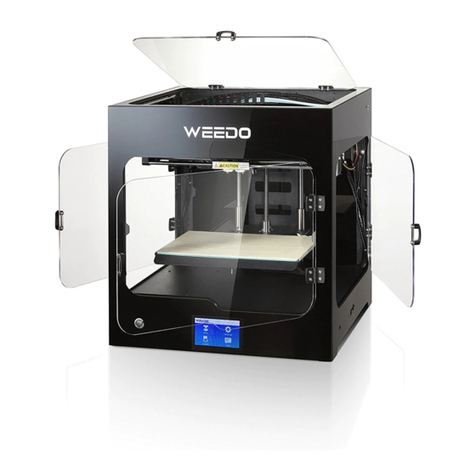

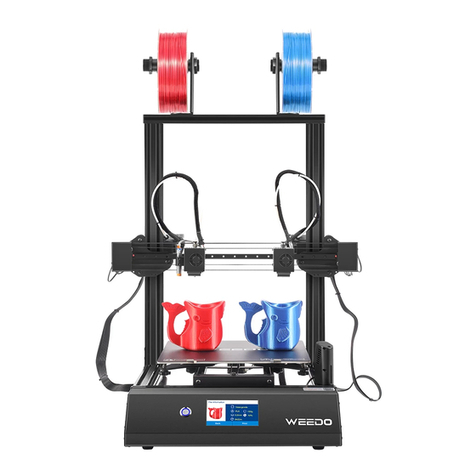

2.1 Appearance Introduction............................................................................................................................4

2.2 Technical Parameters..................................................................................................................................5

3. Install the software of the printer.....................................................................................................................6

3.1 Install Wiibuilder software..........................................................................................................................6

3.2 Wiibuilder Instructions for advanced settings............................................................................................7

4. Print the first model......................................................................................................................................222

4.1. Connect the power supply.....................................................................................................................222

4.2 Loading the filament............................................................................................................................... 222

4.3 Printing preparation................................................................................................................................233

4.4 Printing Mode......................................................................................................................................... 233

4.5 Removing Model....................................................................................................................................... 23

5. Details of the Printing Operation....................................................................................................................24

5.1 Operation Panel Setting............................................................................................................................24

5.1.1 Introduction of the Operation Panel..................................................................................................... 24

5.1.2 Operation Panel Menu........................................................................................................................25

5.1.3 Common operations of the control panel.......................................................................................... 25

5.1.4 Printer Preheat....................................................................................................................................................................26

5.1.5 Debuggung of Printing Function...................................................................................................................................26

5.1.6 Filament Replacement.....................................................................................................................................................27

5.1.7 Printer Jog Bebugging.......................................................................................................................................................27

5.1.9. Auto Home............................................................................................................................................ 29

5.1.10. Stop printing/Pause printing...............................................................................................................30

5.1.11. Adjust the temperature...................................................................................................................... 31

6. Daily Repair and Maintenance.......................................................................................................................... 31

6.1. Printer Daily Maintenance Guide.............................................................................................................31

6.1.1.Clean and replace the nozzle ...........................................................................................................31

6.1.2 Replacing the tape of the glass plate.....................................................................................................32

7. Optical Shaft and Screw Rod Maintenance..............................................................................................................34

8.Printing Nozzle Maintenance and Replacement.......................................................................................................35