6

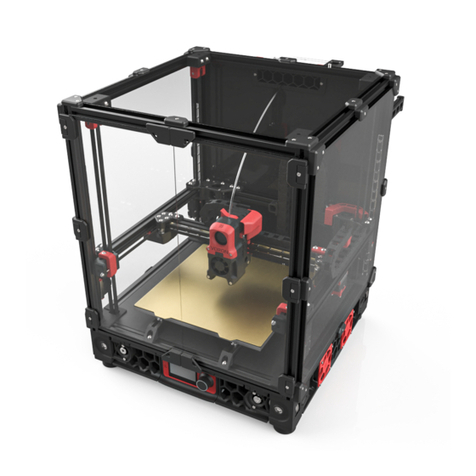

WWW.VORONDESIGN.COM

BUTTON HEAD CAP SCREW (BHCS)

Metric fastener with a domed shape

head and hex drive. Most commonly

found in locations where M5 fasteners

are used.

ISO 738 0 -1

SOCKET HEAD CAP SCREW (SHCS)

Metric fastener with a cylindrical head

and hex drive. The most common

fastener used on the Voron.

ISO 4762

HEX NUT

Hex nuts couple with bolts to create a

tight, secure joint. You’ll see these used in

both M3 and M5 variants throughout this

guide.

ISO 4032

SHIM

Not to be confused with stamped

washers. These are used in all M5 call-out

locations in this manual.

DIN 988

IDLER

GT2 idler used in the motion system of

the Voron.

PULLEY

GT2 pulley used on the motion system

of the Voron.

HARDWARE

POST INSTALL T-SLOT NUT

Nut that can be inserted into the slot of

an aluminium prole. Used in

both M3 and M5 variants throughout this

guide.

HAMMER HEAD NUT

Nut that can be inserted into the slot of

an aluminium prole. Used

exclusively for panel mounting, all other

components use T-Slot nuts.

www.copymaster3d.com

sales@copymaster3d.com