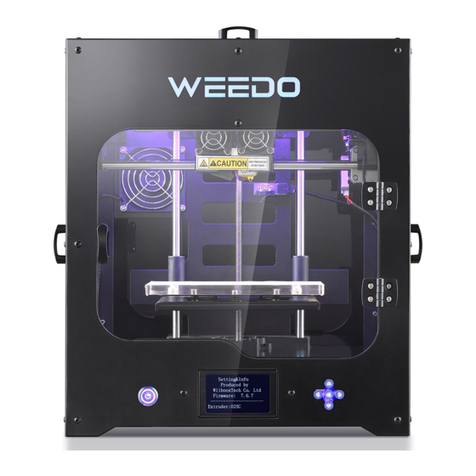

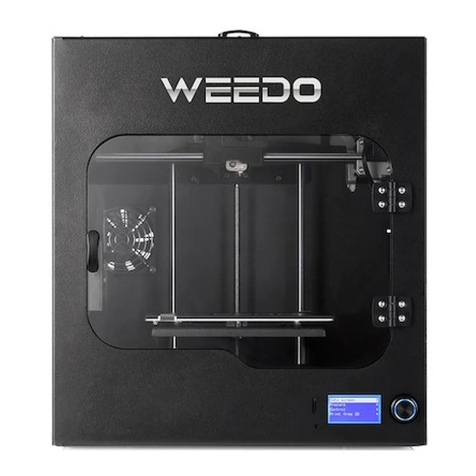

X40/X40V2 3D Printer

Quick Start Guide

INTRODUCTION

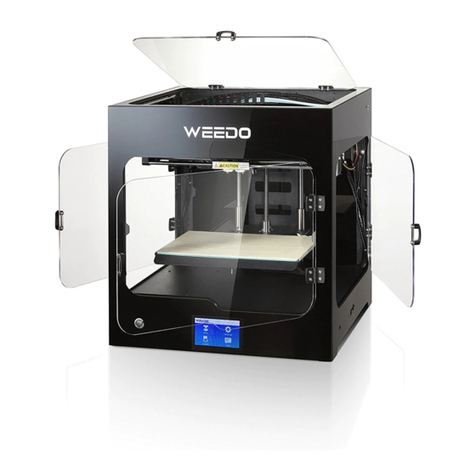

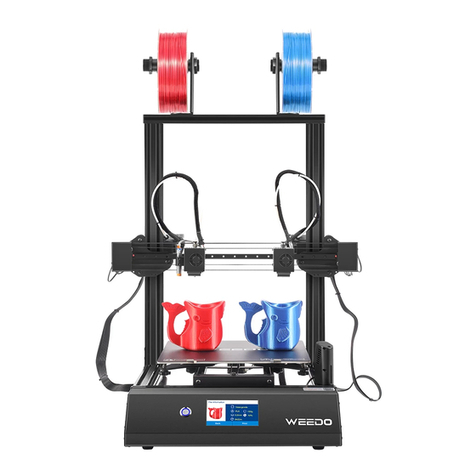

Thank you for purchasing this X40/X40V2 3D Printer! This printer uses the FFF (Fused Filament Fabrication) method of

printing. It features a metal frame, open structure design and heated build platform. It can print 1.75mm ABS, PLA,

Metal fill, Wood fill, and other filament types with melting points below 250°C (Default hot end). The machine with

independent dual extruders can print at a speed up to150mm/s and 300x300x400mm printing area. It can print from

sliced g-code files stored on a micro SD™ card or from our App (Poloprint Pro). It supports auto-leveling, automatic

shut-down, with a 4.3-inch touch screen, a removable and a heated build plate.

CUSTOMER SERVICE

The WEEDO Customer Service department is dedicated to ensuring that your ordering, purchasing, and delivery

experience is second to none. If you have any problem with your order, please give us an opportunity to make it right.

You can contact a WEEDO Customer Service representative through the Live Chat link on our website www.weedo.ltd

or via email at support@weedo3d.com. Check the website for support times and links. You can also search our

product wiki website: www.weedo3dprinter.com.