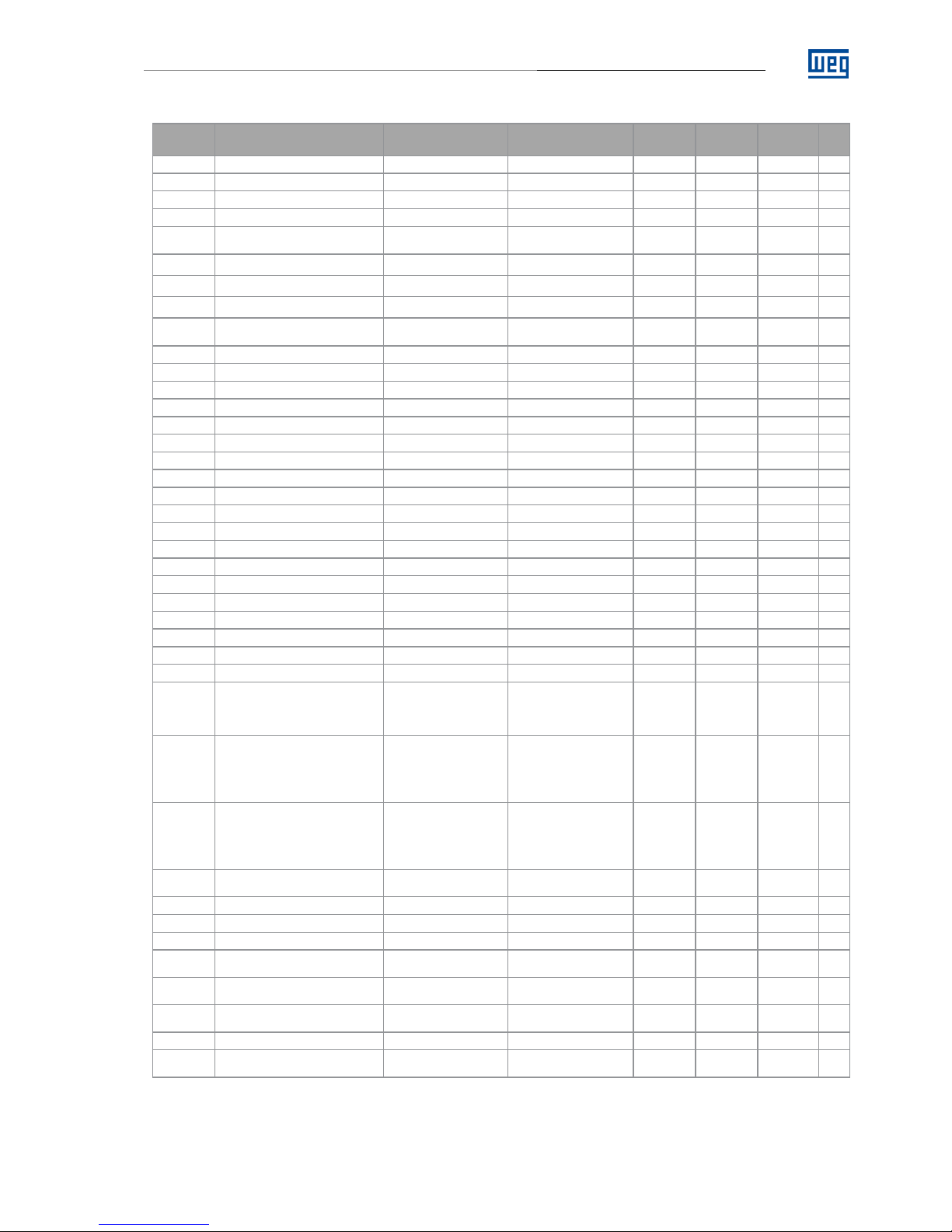

Contents

Solar Pump Drive | 3

CONTENTS

ABOUT THE MANUAL.................................................................................. 4

ABBREVIATIONS AND DEFINITIONS..........................................................................................................4

NUMERICAL REPRESENTATION ................................................................................................................4

QUICK PARAMETER REFERENCE ............................................................. 5

FAULTS AND ALARMS ................................................................................ 7

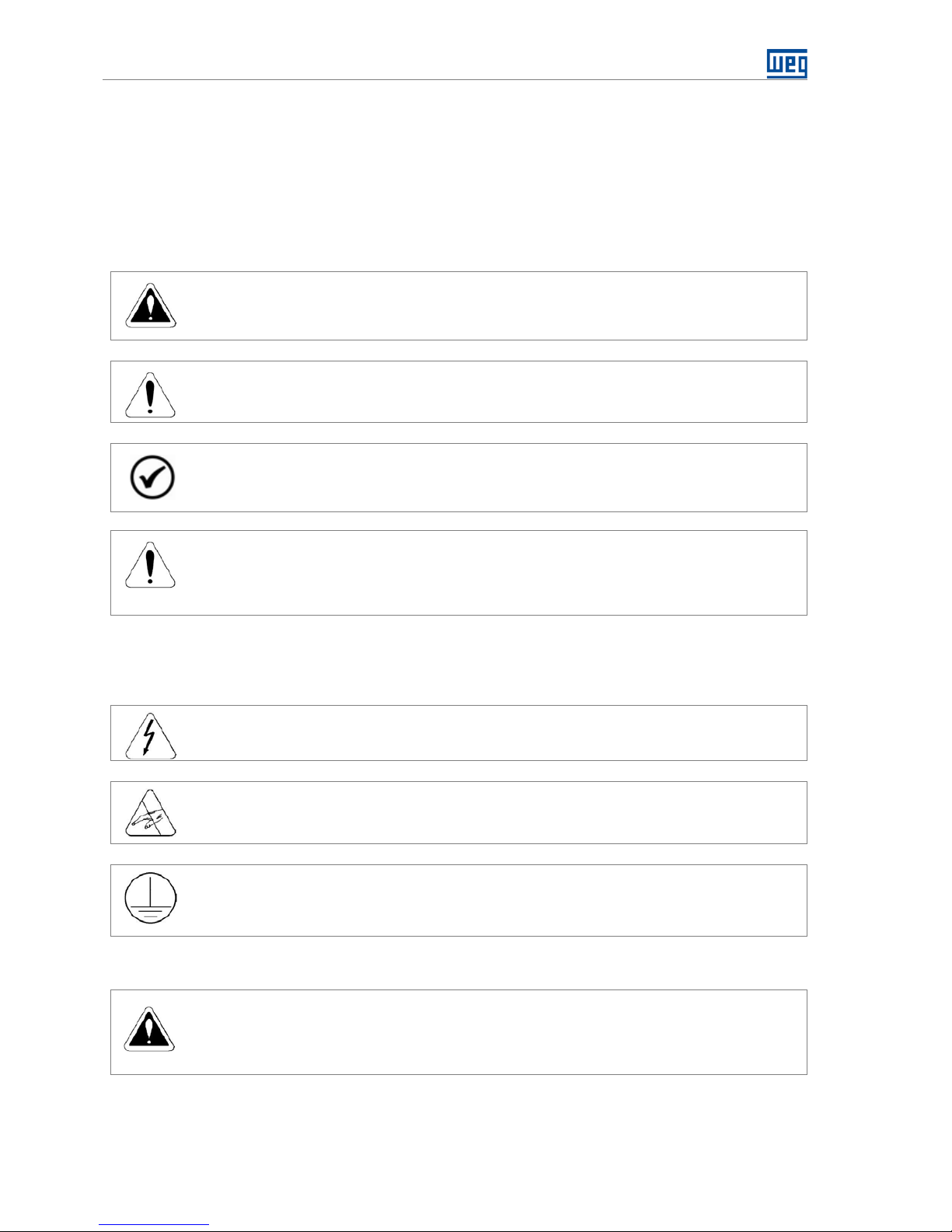

1 SAFETY INSTRUCTIONS .......................................................................... 8

1.1 SAFETY WARNINGS IN THIS MANUAL ................................................................................................8

1.2 SAFETY WARNING IN THE PRODUCT .................................................................................................8

1.3 PRELIMINARY RECOMMENDATIONS..................................................................................................8

2 PHOTOVOLTAIC WATER PUMPING SYSTEM ...................................... 10

2.1 OVERVIEW OF THE CFW500 IN PHOTOVOLTAIC SYSTEMS...........................................................10

2.2 GENERAL CHARACTERISTICS OF THE SOLAR PUMP....................................................................10

3 INSTALLATION ........................................................................................ 12

3.1 SIZING OF PHOTOVOLTAICS SOLAR MODULES .............................................................................12

3.2 CONNECTIONS .....................................................................................................................................13

3.2.1 Frame A

.........................................................................................................................................................14

3.2.2 Frames B, C, D and E

................................................................................................................................15

3.2.3 Frames B, C, D and E with Hybrid Power

............................................................................................16

4 CONTROL METHOD BY MAXIMUM POWER POINT TRACKING......... 17

5 PARAMETERS DESCRIPTION................................................................ 18

5.1 VOLTAGE REGULATOR .......................................................................................................................18

5.1.1 Photovoltaic Generator Data

...................................................................................................................18

5.1.2 Voltage Setpoint Limits

.............................................................................................................................19

5.1.3 Voltage PID Controller

..............................................................................................................................19

5.1.4 System Start Configuration

.....................................................................................................................20

5.1.5 Solar Weg Detector

...................................................................................................................................21

5.2 PRESSURE CONTROLLER ..................................................................................................................22

5.2.1 Pressure PID Controller

............................................................................................................................22

5.2.2 Sleep Mode

..................................................................................................................................................23

5.3 PROTECTIONS ......................................................................................................................................24

5.3.1 Dry Pump

......................................................................................................................................................24

5.3.2 Minimum Output Pressure

.......................................................................................................................25

5.3.3 Maximum Output Pressure

......................................................................................................................25

5.4 CONTROL SETPOINT ...........................................................................................................................26

5.4.1 Reset of P1014 and P1015

.......................................................................................................................26

5.5 HMI MONITORING ................................................................................................................................27

5.6 READING PARAMETERS .....................................................................................................................27

6 POWER UP AND START UP ................................................................... 29