- 1 -

Table of contents

1 Introduction........................................................................................................................ 2

1.1 Notation and symbols......................................................................................................... 2

1.2 Intended use....................................................................................................................... 2

1.3 System requirements.......................................................................................................... 2

1.4 License terms...................................................................................................................... 3

2 Installation .......................................................................................................................... 4

2.1 Software installation........................................................................................................... 4

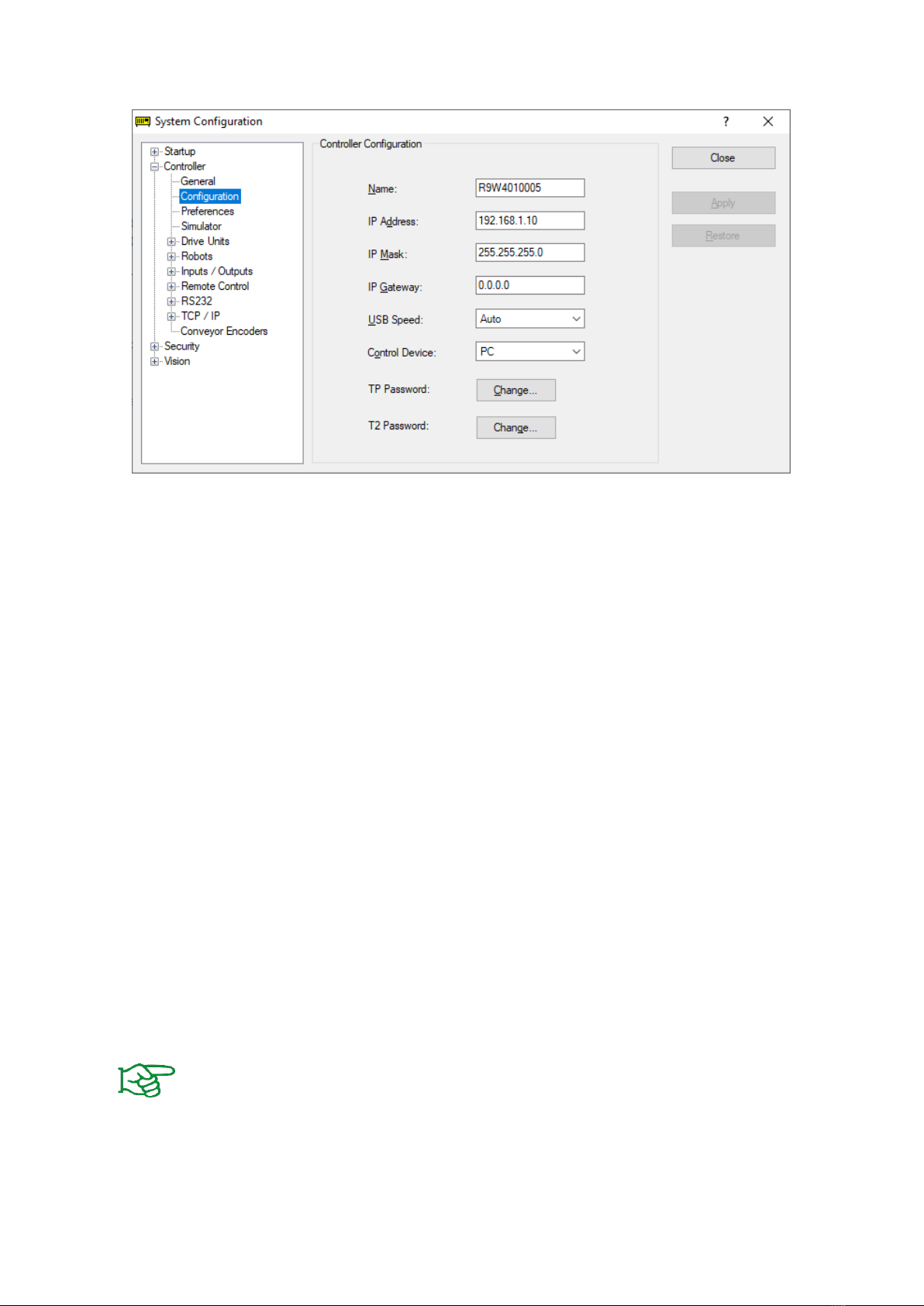

2.2 Network configuration........................................................................................................ 4

2.3 Workpiece detection and monitoring................................................................................. 5

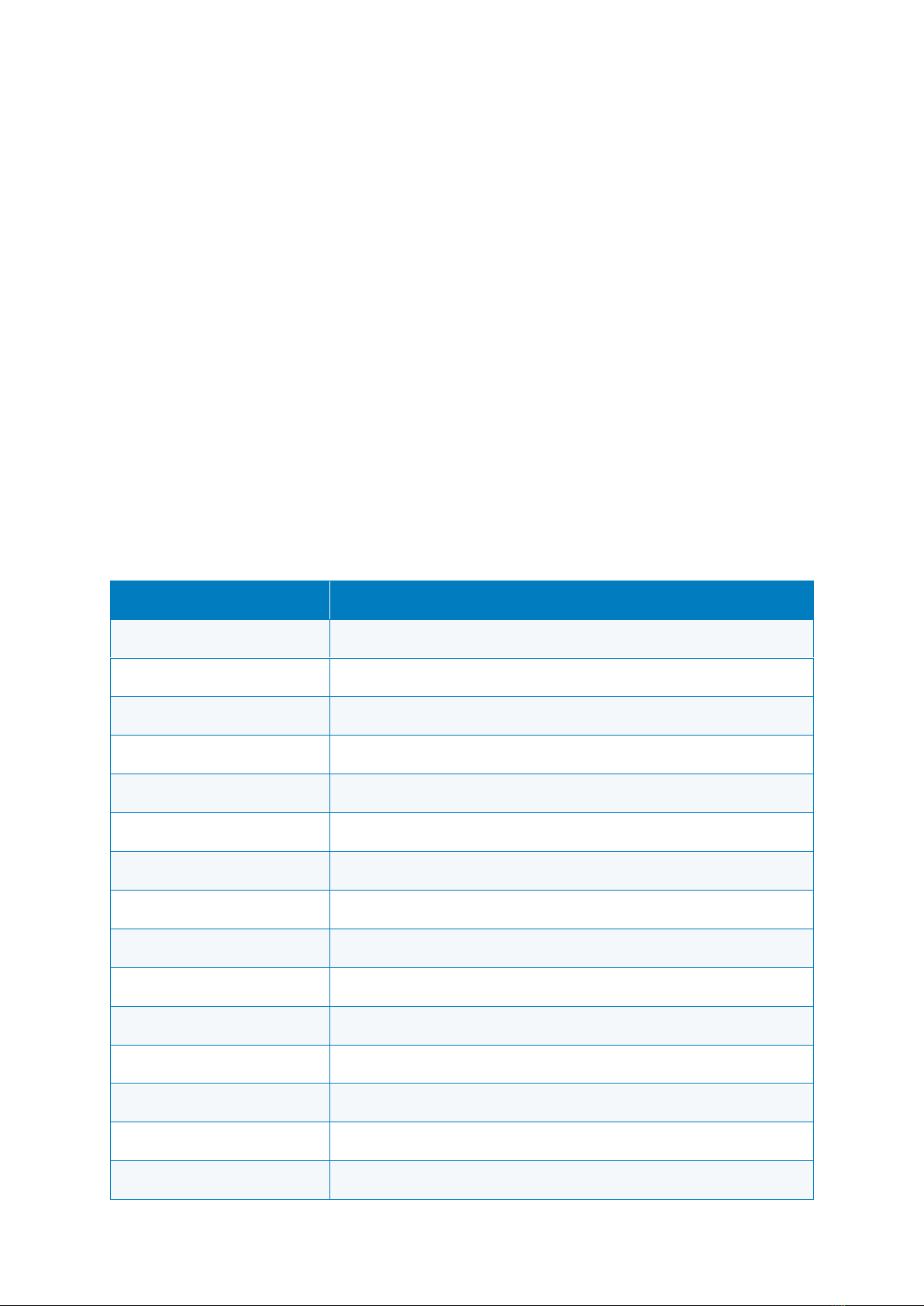

3 Command set reference ..................................................................................................... 7

3.1 Open connection - CONNECT.............................................................................................. 8

3.2 Enable drive - ENABLE......................................................................................................... 9

3.3 Get Grip State –GET STATE .............................................................................................. 10

3.4 Read gripping state from global variable.......................................................................... 11

3.5 Disable drive - DISABLE..................................................................................................... 12

3.6 Disable drives of all modules connected –DISABLE ALL .................................................. 14

3.7 Reference gripper - HOME................................................................................................ 15

3.8 Reference multiple grippers –MHOME............................................................................ 16

3.9 Grip part - GRIP................................................................................................................. 17

3.10 Grip part with multiple grippers –MGRIP ........................................................................ 18

3.11 Release part - RELEASE ..................................................................................................... 19

3.12 Release part with multiple grippers –MRELEASE............................................................. 20

3.13 Get finger position –GET POSITION ................................................................................. 21

3.14 Control gripping force retention - PERMAGRIP................................................................ 22

3.15 Control gripping force retention for multiple grippers –MPERMAGRIP.......................... 23

3.16 Control of the LED display –LED........................................................................................ 24

4 Error Handling................................................................................................................... 25

4.1 Handle errors in GRIPLINK functions ............................................................................... 25

4.2 Handle errors in GRIPLINK background daemon.............................................................. 26