Pick-O-Mat • PM1100 / PM1500 • R02-2014 3/44

Table of contents

1. Introduction ........................................................................................................... 5

1.1. Definition ..................................................................................................... 5

1.2. Intended use ................................................................................................ 5

1.3. Non-intended use ........................................................................................ 5

1.4. Laws / EC Directives / Standards .............................................................. 5

1.5. Further applicable documents ................................................................... 6

1.6. Assembly and instructions manual .......................................................... 6

1.6.1. Definition ....................................................................................................... 6

1.6.2. Explanation of safety instructions in this manual .......................................... 7

1.6.3. Legend .......................................................................................................... 7

1.6.4. Figures .......................................................................................................... 7

1.6.5. Directory of valid pages ................................................................................ 7

1.7. Warranty and liability .................................................................................. 7

2. Safety ..................................................................................................................... 8

2.1. Fundamental safety instructions ............................................................... 8

2.1.1. Operator‘s obligation to exercise diligence ................................................... 8

2.1.2. Requirements to be met by personnel .......................................................... 9

2.2. Safety equipment for the machine ............................................................ 9

2.3. Residual hazards ...................................................................................... 10

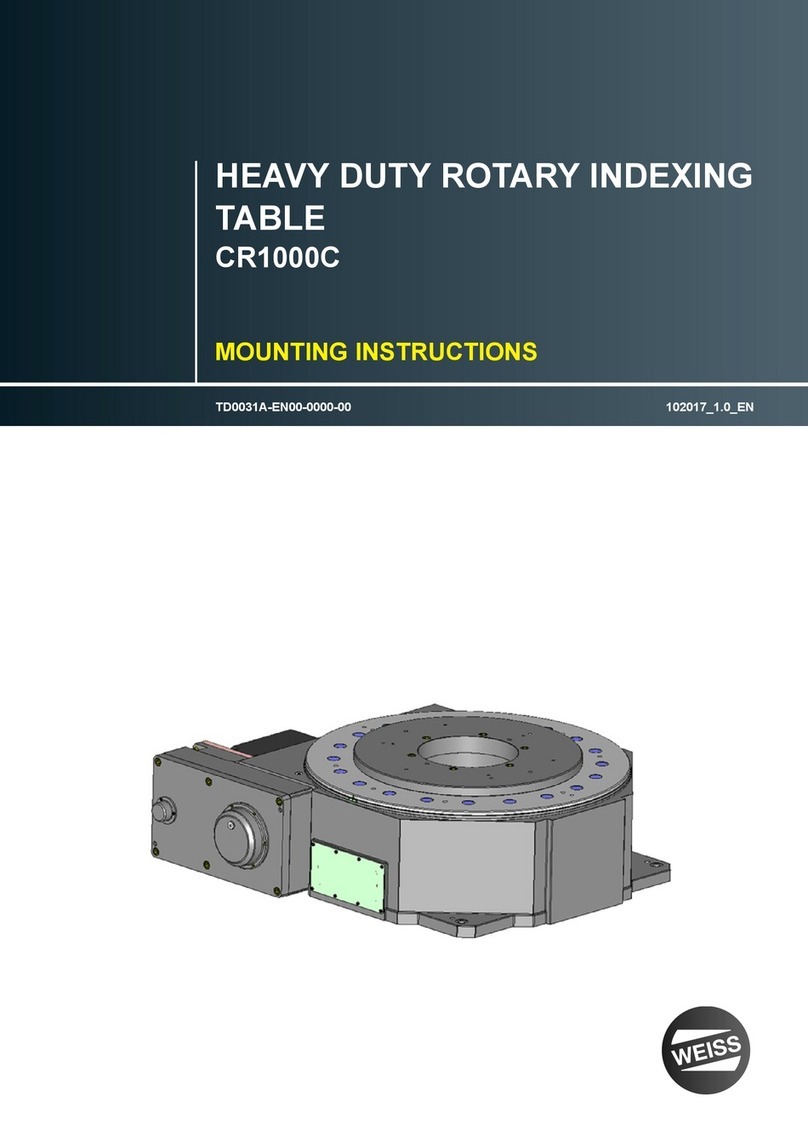

3. Product description ............................................................................................ 11

3.1. Structure .................................................................................................... 11

3.2. Function ..................................................................................................... 12

3.2.1. Complete module ........................................................................................ 12

3.2.2. Lift module .................................................................................................. 12

3.2.3. Press module .............................................................................................. 12

3.3. Movement sequence ................................................................................. 13

3.4. Crash safety .............................................................................................. 14

3.5. Technical data ........................................................................................... 14

3.5.1. General technical data ................................................................................ 14

3.5.2. Type plate ................................................................................................... 14

3.5.3. Scope of delivery ........................................................................................ 15

3.5.4. Weight ......................................................................................................... 15

3.5.5. Sound level ................................................................................................. 15

3.5.6. Strokes ........................................................................................................ 15

3.5.7. Ambient conditions ...................................................................................... 15

3.5.8. Installation positions .................................................................................... 16

3.5.9. Dimensions ................................................................................................. 17

4. Transport ............................................................................................................. 18

4.1. Appliances and auxiliary equipment approved for transportation ...... 18

4.1.1. Transporting of the packed machine ........................................................... 18

4.1.2. Transporting of the unpacked machine ....................................................... 19

4.2. Transport damage ..................................................................................... 19

4.3. Intermediate storage ................................................................................. 20

5. Installation ........................................................................................................... 21

5.1. Safety during installation ......................................................................... 21

5.2. Installation prerequisites ......................................................................... 21

5.2.1. Installation preparation ................................................................................ 22

5.2.2. Operating media / Auxiliary media / Tools .................................................. 22