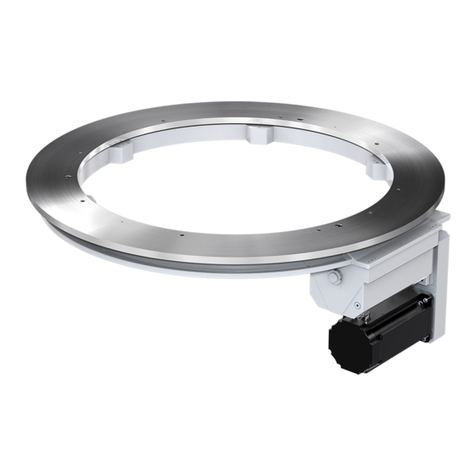

Heavy duty rotary indexing table CR1300C

Table of contents

2 / 44 Mounting instructions_102017_1.0_en

Table of contents

1 Introduction.................................................................................................................................................... 4

1.1 About these mounting instructions..................................................................................................... 4

1.2 Intended use.......................................................................................................................................4

1.3 Predictable incorrect application........................................................................................................ 5

1.4 Applicable documents........................................................................................................................ 5

2 Safety...............................................................................................................................................................6

2.1 Safety messages and hazard categories...........................................................................................6

2.2 Hazard symbols.................................................................................................................................. 7

2.3 Responsibilities of the system integrator and/or operator..................................................................7

2.4 Qualification of personnel...................................................................................................................8

2.5 Personal protective equipment...........................................................................................................8

3 Product description.......................................................................................................................................9

3.1 Overview............................................................................................................................................. 9

3.2 Function description......................................................................................................................... 10

3.3 Nameplate.........................................................................................................................................10

3.4 Type code......................................................................................................................................... 11

3.5 Mounting positions............................................................................................................................11

4 Technical data.............................................................................................................................................. 12

4.1 Technical data "Heavy Duty Rotary Indexing Table"........................................................................12

4.2 Technical data "Motor and Holding Brake"...................................................................................... 12

4.3 Electrical connections....................................................................................................................... 12

4.4 Climatic environmental conditions "Operation"................................................................................ 13

4.5 Climatic environmental conditions "Transportation and Storage".................................................... 13

4.6 Dimensions....................................................................................................................................... 14

4.7 Load data..........................................................................................................................................15

5 Controller...................................................................................................................................................... 16

5.1 Basic information on control.............................................................................................................16

5.2 WEISS GmbH controller/software package (optional)..................................................................... 16

6 Packaging, transportation and storage.....................................................................................................17

6.1 Verification of the delivery................................................................................................................ 17

6.2 Packaging and shipment.................................................................................................................. 17

6.3 Unpacking the product..................................................................................................................... 17

6.4 Transportation................................................................................................................................... 18

6.5 Storage............................................................................................................................................. 18

7 Mounting....................................................................................................................................................... 20