3

GB

English Operating Instructions

Table of Contents

1. Important Safety Notes.............................................................................................................................4

1.1 Intended use........................................................................................................................................5

1.2 Non-intended use.................................................................................................................................5

2. Technical data ..........................................................................................................................................5

3. Transport ..................................................................................................................................................6

4. Your roofer RW3400 .................................................................................................................................6

4.1 Type plate and identification..................................................................................................................6

4.2 Scope of delivery..................................................................................................................................6

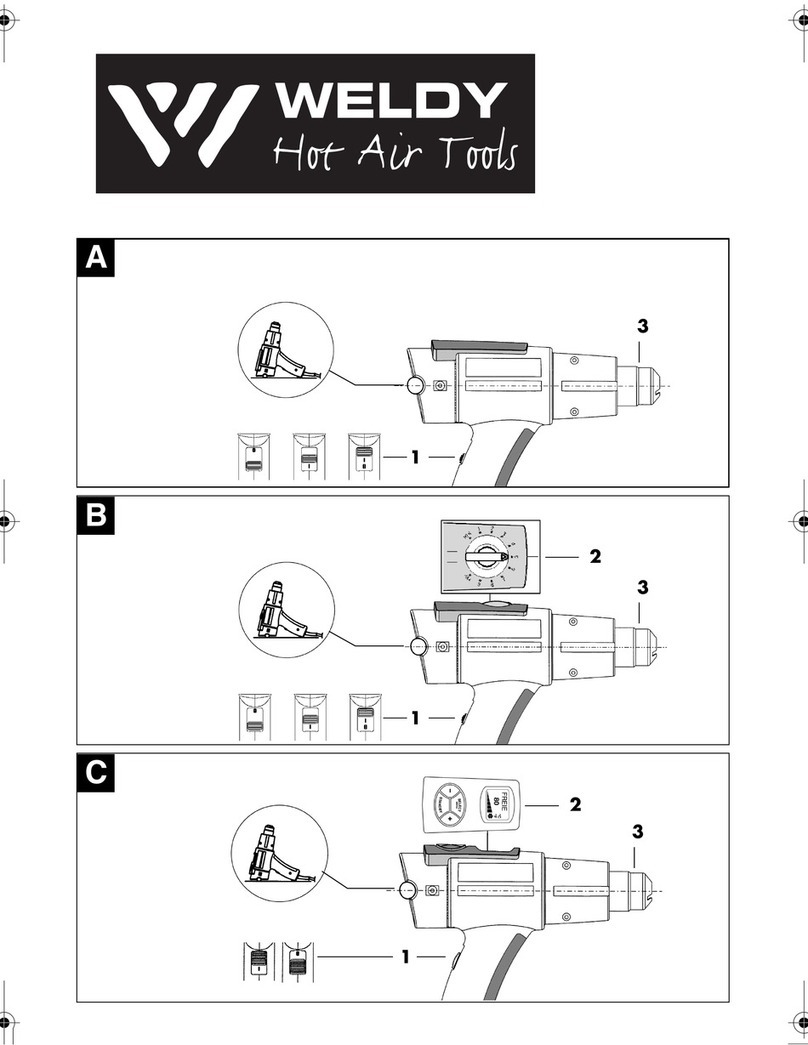

4.3 Overview of the device parts .................................................................................................................7

5. Settings on the roofer RW3400 ................................................................................................................8

5.1 Welding nozzle settings.........................................................................................................................8

5.2 Changing the welding nozzle.................................................................................................................8

5.3 Setting the laser guide..........................................................................................................................9

6. Commissioning your roofer RW3400........................................................................................................9

6.1 Working environment and safety............................................................................................................9

6.2 Operating condition ............................................................................................................................11

6.3 Laser beam guidance .........................................................................................................................11

6.4 Welding parameters ...........................................................................................................................12

6.5 Tool positioning..................................................................................................................................12

6.6 Welding procedure .............................................................................................................................12

6.7 Switching o......................................................................................................................................12

7. Quick Reference Guide for the roofer RW3400.......................................................................................12

7.1 Switching on / Starting........................................................................................................................12

7.2 Switching o......................................................................................................................................12

8. Frequently asked questions, causes and measures...............................................................................13

9. Accessories ............................................................................................................................................13

10. Service and repair ................................................................................................................................13

11. Warranty...............................................................................................................................................13

12. Declaration of conformity.....................................................................................................................13

13. Disposal................................................................................................................................................13