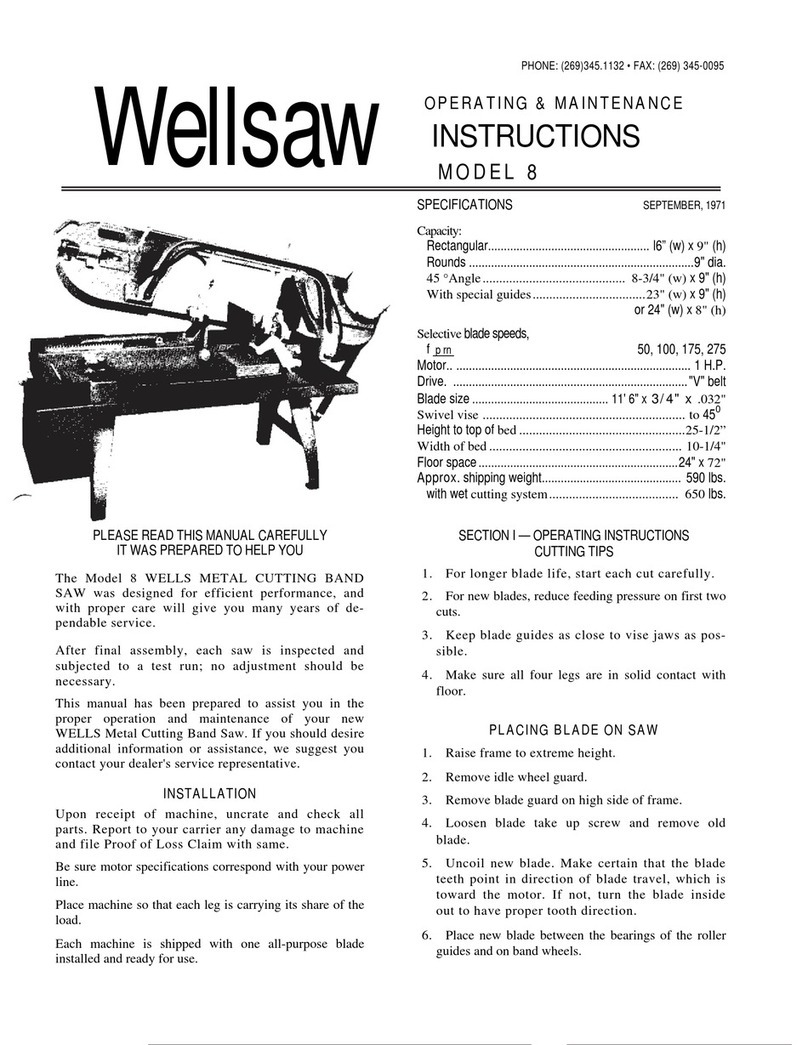

8

Blade Guide Alignment

Up to S/N 1999

To properly align the saw blade for a straight and

accurate cut, do the following:

1. Check the stationary vise jaw. Make sure it is

square. To do this, place a combination square

against the vise jaw slot in the saw bed. Slide the

square toward the stationary vise jaw. Make the

necessary adjustment. If you then find the saw

blade is not square with the stationary vise jaw,

the blade must be adjusted.

2. This adjustment is made with the top two

socket headed screws on the roller adjusting

block of the guide arm. Looking at the drawing

(figure 2) you will see these adjusting screws

labeled “A” and “B”.

3. To make a vertical adjustment of the saw

blade, so that the cut is square from top to bottom,

the blade must be set so that it is perpendicular to

the bed. In making this adjustment, clean the saw

bed first.

4. Set the rule of the combination square on the

saw bed with the end of the rule butted against

the blade above the set of the saw teeth. Use a 1-

1/2 thousandths (.0015”) shim and slide it along

the top and the bottom edge of the rule where it

meets the saw blade. If the shim slides between

the blade and the rule at, either the top or

bottom, the roller supports must be adjusted by

using the bottom socket head screws marked “C”

and “D” to obtain the correct 90 degree angle.

The top ball bearing should be in contact with the

top of the blade at all times. When running the

saw at idle, this contact pressure should be light.

Blade Guide Adjustment

After S/N 1999

To properly align the saw blade for a straight

and accurate cut, do the following:

1. Square the stationary vise jaw. Make sure it is

square to the front of the vise slot. Check by

placing a combination square against the front of

the vise slot in the saw bed. Slide the square

toward the stationary vise. Make any necessary

adjustment to the vise jaw to bring it into square.

Set the combination square so that one leg is

along the face of the stationary vise and check to

see that the blade is square to the vise jaw. If it is

not square, follow the instructions for horizontal

adjustment.

2. Vertical Adjustment. The back of the saw blade

should just touch the carbide back up guide (item

15 in the parts drawing) when the saw is running

but not cutting. To adjust, loosen the two cap

screws 8 [A] and move the block up or down as

required. (Before making this adjustment, be sure

the back of the blade is properly contacting the

flange on both the drive and idle wheels).

3. Horizontal Adjustment. Loosen the two cap

screws 8 [B] securing the horizontal adjusting

block (items 11 & 12 of the parts drawing). Turn

the top adjusting bolt (item 13 of the parts

drawing) to move the blade either in, toward the

saw bed, or out, away from the saw bed.

Normally, the blade comes off the Drive Wheel

with a minimum amount of adjustment needed in

the Horizontal Adjusting Block. The Idle End

adjusting block is more likely to require

adjustment.

4. Blade Tilt. To ensure the blade is perpendicular to

the bed of the saw, loosen the two cap screw 8 [C]

holding the Guide Support (28 & 29 of the parts

drawing) and turn the bottom adjusting bolt (13 of

the parts drawing).

Set the combination square on the saw bed with the

end of the rule butted against the blade above the set

of the teeth. Use a 1-1/2 thousandths (.0015”) shim

and slide it along the top and bottom edge of the rule

where it meets the saw blade. If the shim slides

between the blade and the rule at either the top or

bottom, the blade guides must be adjusted.

5. Safety. Ensure that all bolts are properly

tightened and that all guards are in place before

using the saw.

Recommended Service

Kits for Insurance Against Downtime

(before S/N 2000)

1 year

100133-004 Rotary Blade Brush 1 reqd.

2 years

100416-003 Bearing 4 reqd.

100406-002 Bearing 2 reqd.

105454-005 VS Belt 1 reqd.

100133-004 Rotary Blade Brush 1 reqd.

100166-450 Blade Brush V Belt 1 reqd.

106317 Fixed Carbide Guide 2 reqd.

106319 Spring Back Carbide 2 reqd.

After s/n 2000

1 year

100133-004 Rotary Blade Brush 1 reqd.

2 years

100416-001 Bearing 4 reqd.

152153 Top Carbide Guide 2 reqd.

106317 Fixed Carbide Guide 4 reqd.

105454-005 VS Belt 1 reqd.

100133-004 Rotary Blade Brush 1 reqd.

100166-450 Blade Brush V Belt 2 reqd.