6

OPERATION

READ CAREFULLY

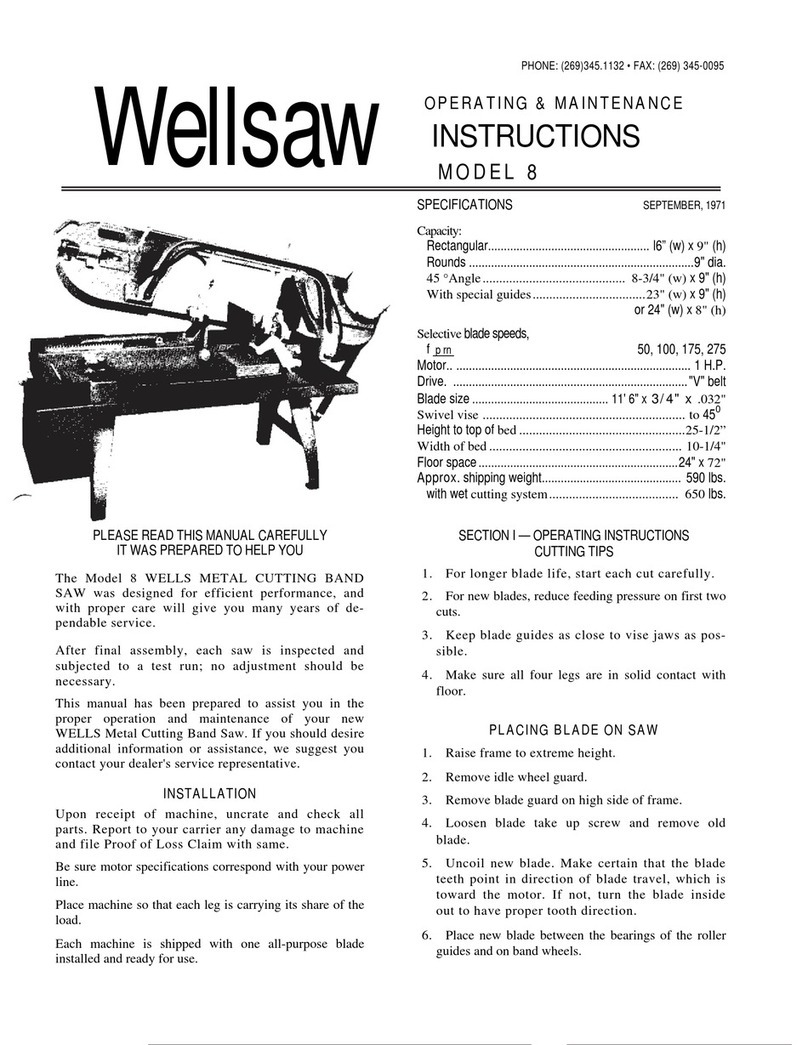

The MODEL V20 METAL CUTTING BAND SAW is designed for

efficient performance. With proper care, it will give you many years

of dependable service. READ THIS MANUAL CAREFULLY BE-

FORE OPERATING YOUR NEW SAW.

After final assembly, each saw is inspected and tested. No adjust-

ment should be needed.

This manual has been prepared to assist you in the operation and

maintenance of your new saw. If you desire additional information

or assistance, please contact your dealer’s service representative.

PLACING BLADE ON SAW

1. Disconnect electrical supply. Wear gloves and safety goggles

throughout the blade changing operation!

2. Open front cover, swing blade guard aside and move tie-bar at

front bottom of table aside.

3. Hold blade carefully while loosening blade tension screw. Re-

move blade.

4. Uncoil new blade. Make certain that blade teeth point in direc-

tion of band travel; downward toward the table.

5. Place new 14’9” blade on band wheels and in saw guides.

The back of the blade should make contact with the back-up

bearing in both upper and lower blade guides and the bearing

on the frame. The frame bearing has a groove in it to help

with proper adjustment. Turn the band wheel by hand to ver-

ify proper band tracking on wheels and through and through

blade guides. (When changing blade sizes, adjust both upper

and lower back-up bearings.)

6. Reposition top and bottom blade guards, and close and latch

covers. Door interlocks prevent saw from being turned on

when doors are open.

7. Start the saw at slow speed to check proper blade installation

before cutting.

SWITCHES

Always press the stop switch to turn off the saw before opening

the cover, making any adjustment, or performing any maintenance.

Restarting is required after the saw automatically stops from power

interruption (undervoltage protection) or overloading.

BLADE GUIDES

When changing blade sizes, adjust the guides to the blade after it

is installed on the band wheels. The side guides should contact

the blade without galling and be recessed behind the toothed por-

tion of the blade. Each side guide is mounted on an eccentric stud

secured by anAllen screw which provides adjustment for sideways

clearance. Back-up guides are set to contact the back of the blade

for blade tracking on the wheels. If necessary, the back-up bearing

contacts the back of the blade. Be sure that both upper and lower

blade guides are adjusted so that the blade travels in a straight line.

(The work table is adjusted to the blade after the blade is installed

and the guides are properly adjusted).

The top blade guide should always be placed as

close to the workpiece as possible to reduce the amount of ex-

posed blade. Keep all guards on the machine and in position when

the saw is in use.

ROTATING BLADE GUIDES

This saw is equipped with blade guides that can be rotated a full

90° to allow cutting very long materials. To rotate these guides:

1. Remove the throat plate from the center of the work table.

2. Loosen the cap screws on both the top and bottom blade guide

mounts.

3. Rotate the Blade GuideAssemblies to guide the blade into the

desired direction. Tighten the cap screws and re-install the

throat plate. It is not normally necessary to loosen the blade

tension when rotating the guide assemblies.

Adjust the Blade Guard as close to the work sur-

face as practical to limit the amount of exposed saw blade.

BLADE BRUSH

Keep the brush positioned so that the brush bristles contact the

toothed portion of the blade.

TABLE

To adjust the angle of the table to the blade, loosen the table pivot

clamp screw under the rear of the table. Pivot the table to the de-

sired angle and tighten the clamp screw.

VARIABLE FREQUENCY MOTOR CONTROLLER

To adjust the bandspeed, burn the small knob on the front of the

saw. Band speeds are indicated on the legend plate behind te

knob. The gearbox has high and low ranges.

WHEEL PITCH

If the blade tends to run off the front of the top (idle) wheel, loosen

the locknuts on the back of the slide block, tighten set screw 1/4

turn and reset the locknuts. Repeat if necessary. The blade does

not have to be loosened to adjust wheel pitch.

To make a similar adjustment on the the lower (drive) wheel, loosen

the lower pair of cap screws on the wheel mounting plate, loosen

the corresponding pair if set screws one turn and tighten the cap

screws.

After making a wheel pitch adjustment, turn the wheel several

times by hand to confirm proper blade tracking. When everything

appears normal, turn the saw on at slow speed to confirm proper

tracking of the blade.

LUBRICATION

Lubricated-for-life components are used through the saw, including

the motor. The blade tensioning screw and slide should be oiled

and greased occasionally for ease of operation.

Blade Tensioning Screw:

1. Inspect monthly.

2. Use Lubriplate grease 130-A or equivalent.

3. Viscosity at 100°F: SUS 750-800.

4. Military Specification: Mil-G-46003

V-20 OPERATION AND MAINTENANCE