3

Copyright © 2011 by Wenger Corporation

All rights reserved. No part of the contents of this manual may be reproduced, copied, or transmitted in

any form or by any means including graphic, electronic, or mechanical methods or photocopying,

recording, or information storage and retrieval systems without the written permission of the publisher,

unless it is for the purchaser's personal use.

Printed and bound in the United States of America.

The information in this manual is subject to change without notice and does not represent a commitment

on the part of Wenger Corporation. Wenger Corporation does not assume any responsibility for any

errors that may appear in this manual.

In no event will Wenger Corporation be liable for technical or editorial omissions made herein, nor for

direct, indirect, special, incidental, or consequential damages resulting from the use or defect of this

manual.

The information in this document is not intended to cover all possible conditions and situations that might

occur. The end user must exercise caution and common sense when assembling or installing Wenger

Corporation products. If any questions or problems arise, call Wenger Corporation at 1-800-887-7145.

The Legacy Acoustical Shell is manufactured by:

Wenger Corporation

555 Park Drive

Owatonna, N 55060

1-800-4WENGER (493-6437) • 1-507-455-4100

www.wengercorp.com

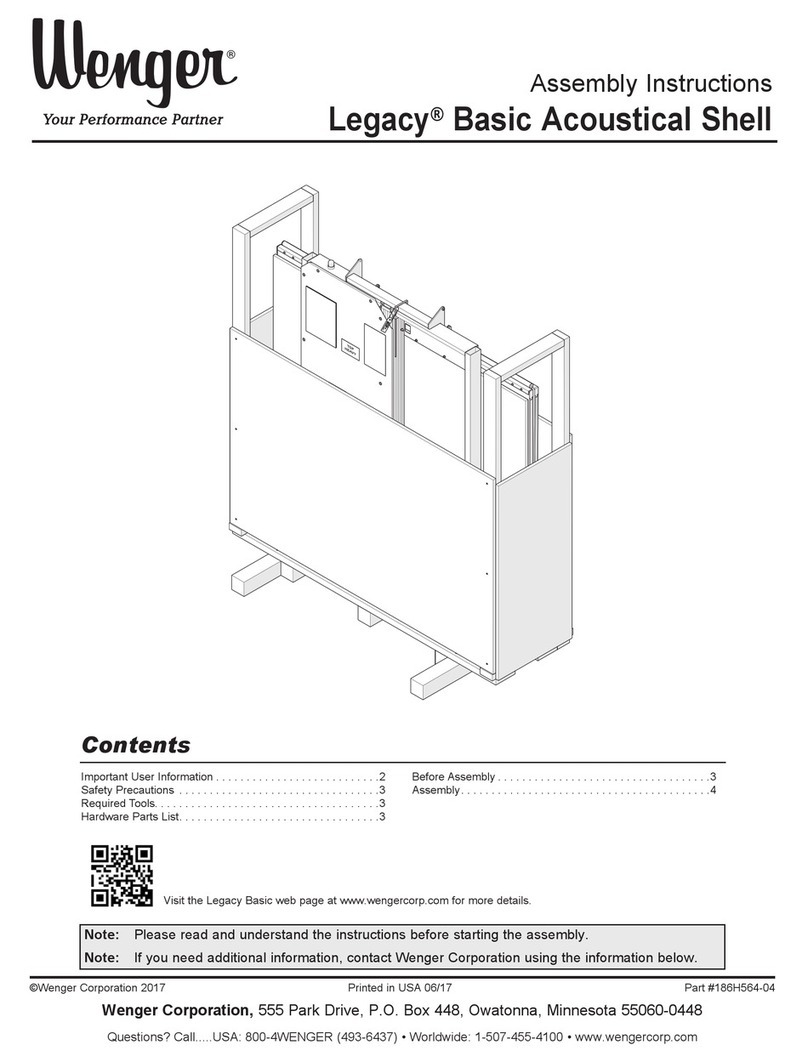

•This product is designed to be an acoustical reflector for vocal or instrumental groups. Shells may

also be used as a backdrop or as a screen for other functions such as speeches and ceremonies.

•This product is intended for indoor use in normal ambient temperature and humidity conditions.