5

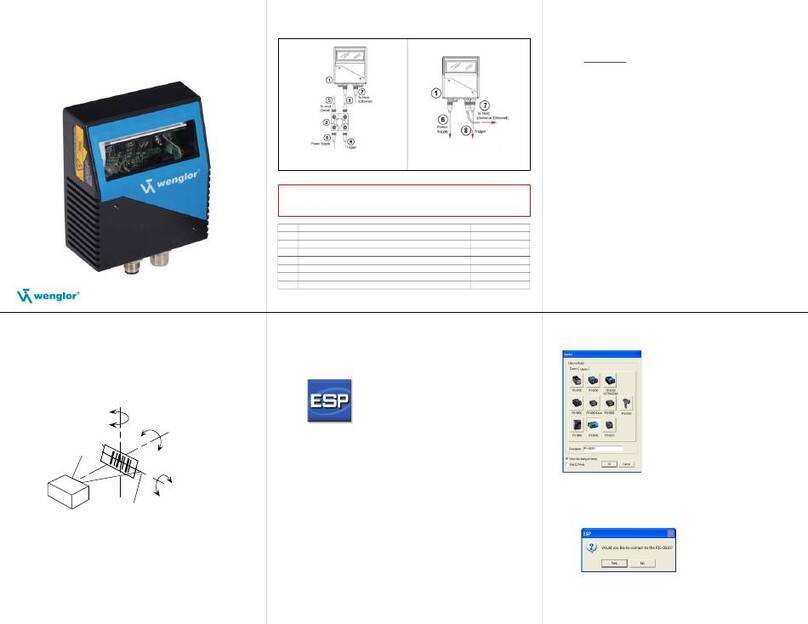

1D/2D and Barcode Scanners

1. General

1.1. Information Concerning these Instructions

• These instructions apply to the product with ID code BLN0x1R20.

• They make it possible to use the product safely and efficiently.

• These instructions are an integral part of the product and must be kept on hand for the entire duration of its

service life.

• Local accident prevention regulations and national work safety regulations must be complied with as well.

• The product is subject to further technical development, and thus the information contained in

these operating instructions may also be subject to change. The current version can be found at

www.wenglor.com in the product’s separate download area.

NOTE!

The operating instructions must be read carefully before using the product and must be

kept on hand for later reference.

1.2. Explanations of Symbols

• Safety precautions and warnings are emphasized by means of symbols and attention-getting words

• Safe use of the product is only possible if these safety precautions and warnings are adhered to

• The safety precautions and warnings are laid out in accordance with the following principle:

ATTENTION-GETTING WORD!

Type and Source of Danger!

Possible consequences in the event that the hazard is disregarded.

• Measures for averting the hazard.

The meanings of the attention-getting words, as well as the scope of the associated hazards, are listed below.

DANGER!

This word indicates a hazard with a high degree of risk which, if not avoided, results in

death or severe injury.

WARNING!

This word indicates a hazard with a medium degree of risk which, if not avoided, may result

in death or severe injury.

CAUTION!

This word indicates a hazard with a low degree of risk which, if not avoided, may result in

minor or moderate injury.

ATTENTION!

This word draws attention to a potentially hazardous situation which, if not avoided, may

result in property damage.