CFW11 | 7

Addendum to the Programming Manual CFW-11 V5.8X

Fault/Alarm Description Possible Causes

F028

Motor Stop Time Exceeded

Motor stop time exceeded fault. Motor being dragged by the load.

Sensorless control with orientation loss.

F098

PM ID Fault

Fault related to the identification of the starting

position in the PM motor control.

Motor shaft spinning during procedure to identify

the starting position.

Setting of P0662 too low for the motor.

F167

PM Spin Fault

Feedback obtained via encoder does not

match the commanded direction of rotation.

Note:

It may be disabled by setting P0678 = 0.

Motor shaft spinning during procedure to identify

the starting position.

Setting of P0662 too high for the motor.

F168

PM ID Overcurrent

Output overcurrent fault during procedure

to identify the starting position.

Motor shaft spinning during procedure to identify

the starting position.

Setting of P0662 too high for the motor.

F182

Pulse Feedback Fault

Fault in the output pulse feedback. No motor connected or the motor connected to

the inverter output is too small.

Possible defect on the internal circuits of the

inverter.

Possible solutions:

Reset inverter and try again.

Set P0356 = 0 and try again.

A415 (10)

High Temperature on the External Rectifier

Signals related to the setting of parameters

P0832 and P0833.

High ambient temperature around the rectifier

and high output current.

Rectifier heatsink too dirty.

A708

SoftPLC Application Stopped

SoftPLC Application is Not Running. Without SoftPLC application (P1000 = 0 and

P1004 = 1)

SoftPLC Application is stopped (P1001 = 0 and

P1000 = 3).

SoftPLC status indicates application incompatible

with the CFW11 firmware version.

F709

SoftPLC Application Stopped

SoftPLC Application is Not Running. Without SoftPLC application (P1000 = 0 and

P1004 = 2)

SoftPLC Application is stopped (P1001 = 0 and

P1000 = 3).

SoftPLC status indicates application incompatible

with the CFW11 firmware version.

F711

SoftPLC Execution Failed

SoftPLC Execution Failed. Incompatible application.

Uploading of the application failed.

Program generated with an old version of the WLP.

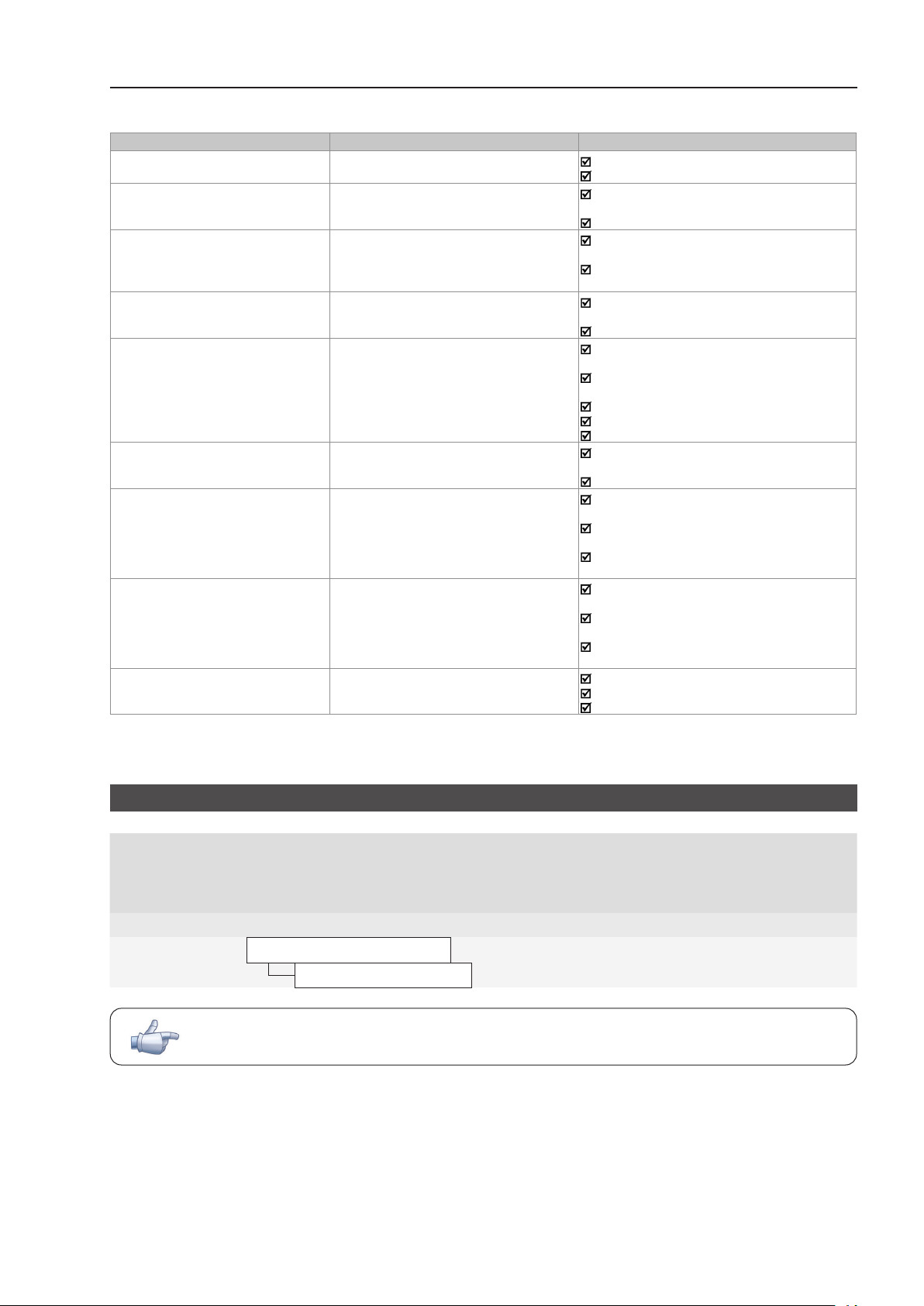

5.4 HMI [30]

P0201 - Language

Adjustable

Range:

0 = Português

1 = English

2 = Español

3 = Deutsch

Factory

Setting:

0

Properties:

Access Groups

via HMI:

01 PARAMETER GROUPS

30 HMI

NOTE!

French language removed.