FRANÇAIS

Page 18

Avertissement :

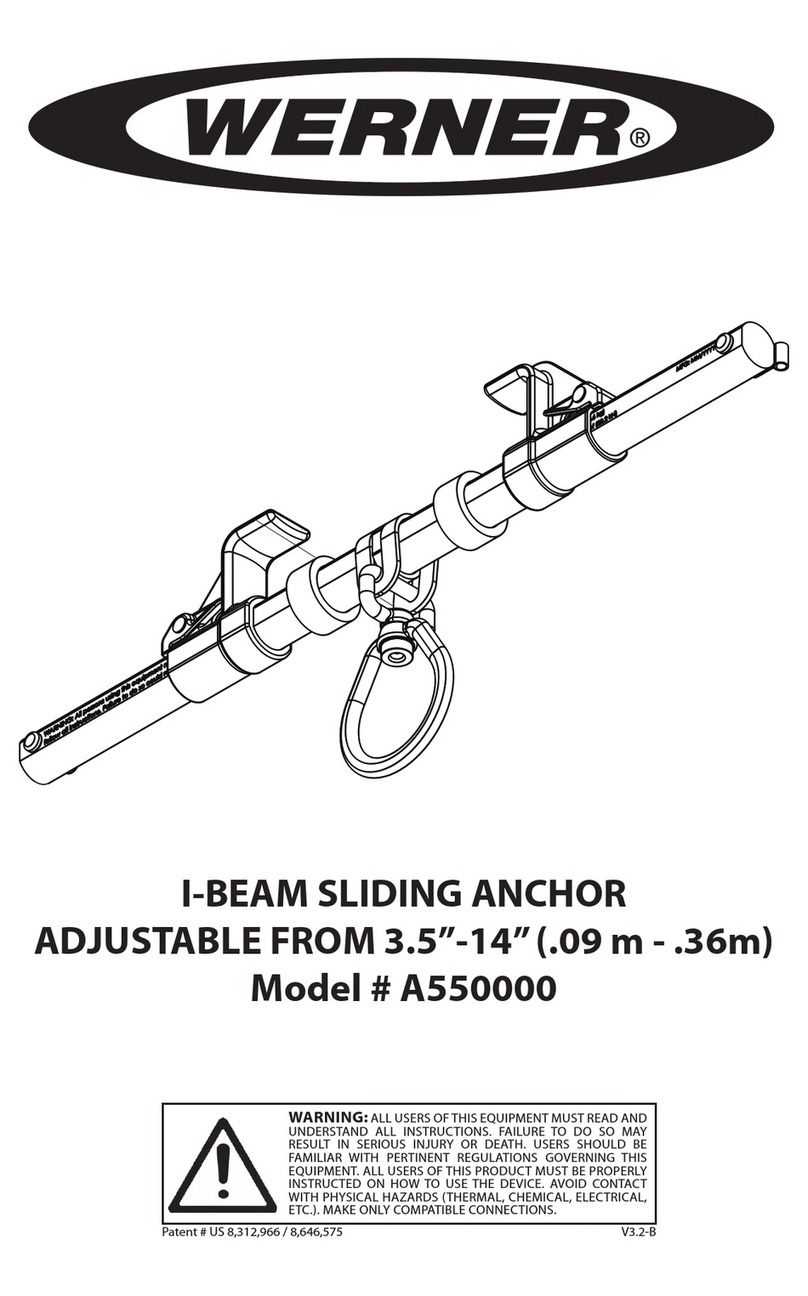

Ce produit est juste une partie d’un système pour empêcher une personne

de tomber, la positionner au travail, restreindre son déplacement, faciliter

sa montée ou sa récupération. Il doit être correctement apparié à d’autres

composants pour former un système complet et fonctionnel. L’utilisateur

doit pour chacun de ces composants comprendre sa fonctionnalité et

suivre les instructions de son constructeur. Les normes CSA, ANSI et OSHA

exigent qu’une formation sur l’utilisation de ces produits soit fournie par

une personne compétente. L’utilisateur doit recevoir ces instructions, doit

les lire et les respecter, puis consulter la personne compétente qui supervise

son travail en cas de questions sur n’importe quelle partie des instructions.

L’employeur doit fournir de la formation sur la bonne utilisation, l’inspection

et l'entretien de tous les composants dans le système, et ces instructions

peuvent être utilisées dans le cadre de cette formation. L’équipement doit

être utilisé UNIQUEMENT en conformité avec ces instructions, les normes et

réglementations locales,les normes OSHA CSA et ANSI applicables, et le plan

pour la sécurité de l’employeur.

SI VOUS AVEZ DES QUESTIONS SUR UNE QUELCONQUE PARTIE DE

CES INSTRUCTIONS, SUR L’ÉQUIPEMENT LUI-MÊME OU SUR SON

UTILISATION CORRECTE,VEUILLEZ CONTACTER WERNER CO. POUR

EN SAVOIR PLUS.

I. Avant d’utiliser la corde de sécurité

Avant d’utiliser cet équipement, l’utilisateur doit suivre certaines étapes an

de s’assurer qu’il est en bon état et utilisable sans risques.

a. Inspection

Examinez l’ensemble de l’équipement soigneusement, quotidiennement

avant son utilisation, ou périodiquement via une personne compétente

autre que l’utilisateur. Vériez l’état de chaque composant. En cas où

des dommages, des points anormaux ou une usure excessive seraient

décelés, le produit doit être retiré du service.

1. Contrôlez d’abord les indicateurs de charge d’impact. Pour les cordes

avec blocs de choc, le couvercle transparent en plastique permet une

vision complète. Contrôlez la zone près de l’étiquette d’INDICATEUR

DE CHUTE si la couture d’absorbeur de choc est intacte. S’il y a une

quelconque indication de charge d’impact la corde doit être mise hors

service et détruite. Enlevez du service toute corde de sécurité qui

montre des indications de charge d’impact.

2. Contrôlez le sanglage pour déceler des coupures, abrasions, brûlures,

projections de soudure, ou décoloration ayant pu être causée par une

exposition chimique.