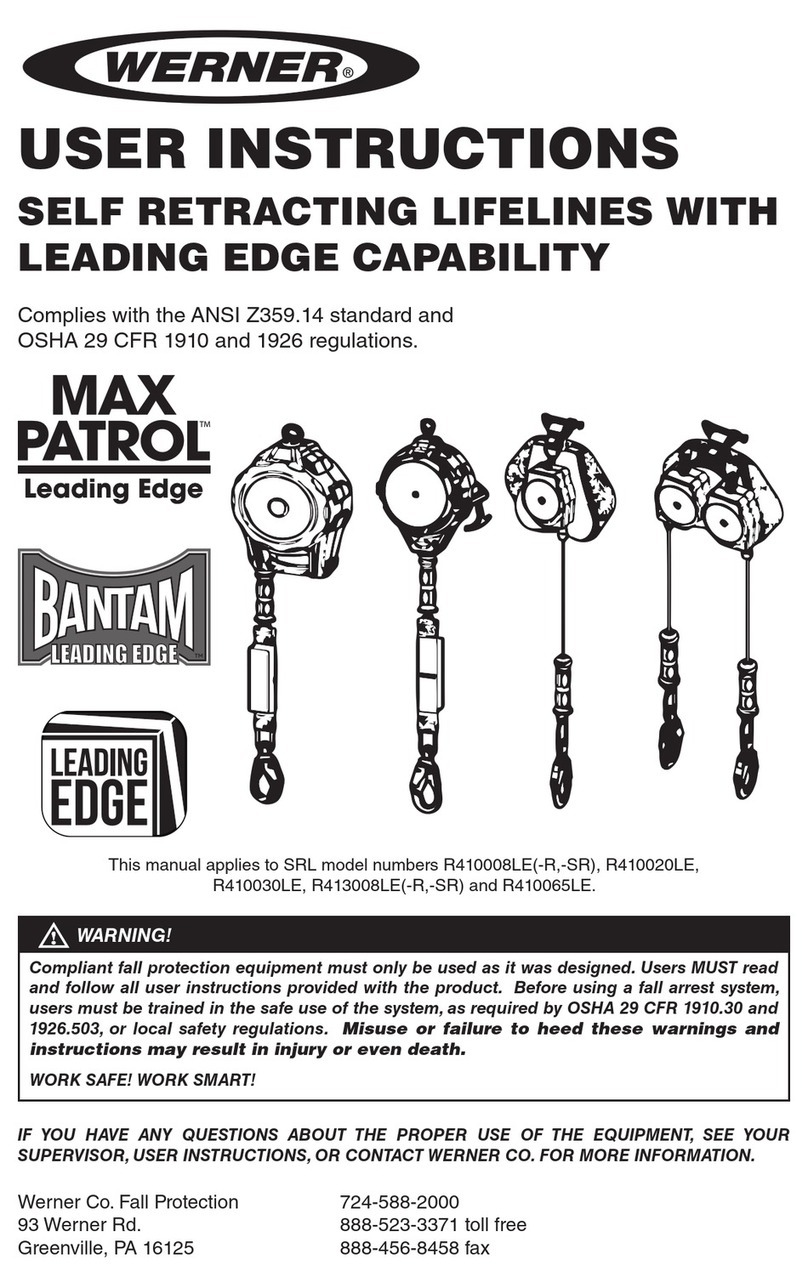

Werner A510300 User manual

Reusable Swivel Concrete Anchor

User Instruction Manual

A510300

WARNING: Compliant fall protection equipment must only

be used as it was designed and adhere to the hierarchy of controls as

discussed in ANSI Z359.2. Users MUST read and follow all user instructions

provided with the product. Before using a fall arrest system, users must be

trained in the safe use of the system, as required by OSHA 29 CFR 1910.30

and 1926.503, or local safety regulations. Misuse or failure to heed

these warnings and instructions may result in injury or even

death.

WORK SAFE! WORK SMART!

Important

Before use, the user must read and understand these User Instructions. Keep

these User Instructions for reference.

WARNING:

1. Failure to follow all instructions and limitations on the use of the

Reusable Swivel Concrete Anchor may result in serious personal

injury or death.

2. Minors, pregnant women and anyone with a history of either back or

neck problems should not use this equipment.

3. Do not use the Reusable Swivel Concrete Anchor without proper

training from a “competent person” as dened by OSHA 29 CFR

1910.140(b) and 1926.32(f).

4. Not all fall protection components are rated for the same user weight

capacity. Only use components rated for the same weight capacity.

5. Caution must be taken when using the Reusable Swivel Concrete

Anchor or other fall protection equipment near moving machinery,

electrical hazards, sharp edges, or abrasive surfaces. Contact with

these elements may cause equipment failure, personal injury, or

death.

6. Remove any surface contamination such as concrete, stucco, roong

material or foreign material that could accelerate cutting or abrasion

or affect the performance of the anchorage connector before

installing.

7. Do not expose the Reusable Swivel Concrete Anchor to chemicals or

harsh solutions which may have a harmful effect.

8. Personal fall arrest systems, including the Reusable Swivel Concrete

Anchor, must be inspected prior to each use for wear, damage and

other deterioration. Defective components must be immediately

removed from service in accordance with the requirements of OSHA

29 CFR 1910.140 and 1926.502.

9. Striking objects horizontally due to the pendulum effect of a swing

fall may cause serious injury or death.

10. Do not use if inspection reveals any defect, wear, damage,

deterioration, inadequate maintenance, or unsafe condition.

11. Do not use any equipment that has been subjected to the forces of

arresting a fall or if any part of the Reusable Swivel Concrete Anchor

is damaged or non-functional.

12. Only Werner Co., or persons or entities authorized by Werner Co., may

make repairs or alterations to the equipment.

13. Alterations or misuse may result in serious personal injury or death.

purpose

Werner Reusable Swivel Concrete Anchors are designed to function as an

interface between the anchorage and travel restraint, work positioning, fall

arrest or rescue system.

use InstructIons

1. Before using a personal fall arrest system, employees must be trained

in accordance with the requirements of OSHA 29 CFR 1910.30 and

1926.503 in the safe use of the system and its components.

2. The complete fall arrest system must be planned (including all

components, calculating fall clearance, and swing fall) before using.

3. Users must have a rescue plan, and the means at hand to implement it,

that provides for the prompt rescue of the user in the event of a fall, or

assures that the user is able to rescue themselves. A fall over an edge

may require special rescue measures.

4. Store the Reusable Swivel Concrete Anchor in a cool, dry, clean

environment, out of direct sunlight, when not in use.

5. After a fall occurs on the system, immediately remove from service for

inspection by a competent person.

6. Werner Co. will provide design information upon request.

7. Field serviceability testing is not required and is not recommended to be

performed by the user.

use LImItatIons

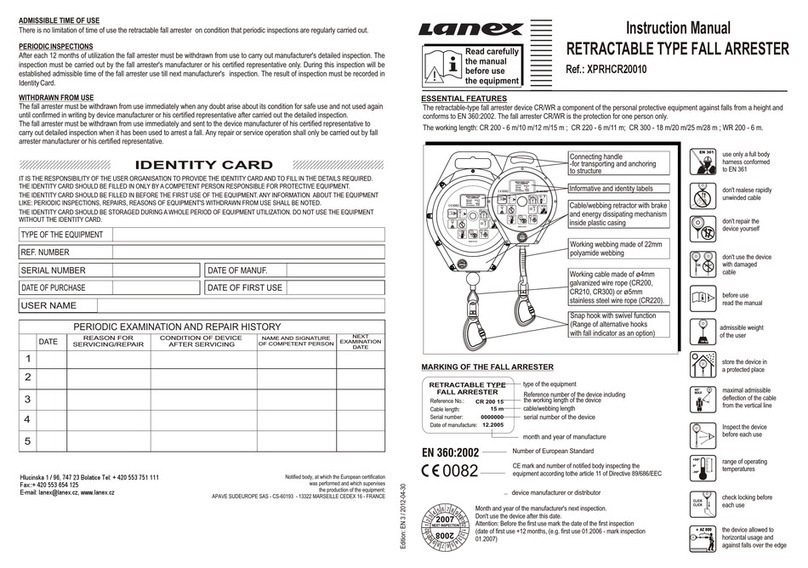

The Reusable Swivel Concrete Anchor has been tested in compliance with

the requirements of ANSI/ASSE Z359.7 as a Type A anchorage connector.

Compliance and testing covers only the hardware and does not extend to the

anchorage and substrate to which the anchors are attached.

1. PLAN: Establish a plan as to where the Reusable Swivel Concrete Anchor

will be installed and when during the construction process.

2. CONCRETE SPECIFICATION: The Reusable Swivel Concrete Anchor

must only be mounted in minimum 3000-psi concrete.

3. ANCHORAGE: The Reusable Swivel Concrete Anchor must only be

used on structures capable of supporting loads applied in all directions

permitted by the fall arrest system of at least: A) no less than 5,000

pounds (22.2 kN) for non-certied anchorages; or B) at least two times

the maximum arresting force for certied anchorages; C) according to

ANSI Z359.6, Specications and Design Requirements for Active Fall

Protection Systems or when strength is unknown.

4. SUBSTRATE: Concrete substrates to which the Reusable Swivel Concrete

Anchors are attached must be in good condition and free of cracks, holes,

air pockets, holes, or defects that may weaken the substrate. Concrete

substrates must be secured to the building and be able to support

anchorage requirements. Only connect the Reusable Swivel Concrete

Anchor according to the instructions.

5. Do not attach Reusable Swivel Concrete Anchor to deteriorated concrete,

unstable structure, partially constructed substrates, unknown concrete, or

structure that will not qualify as an anchorage.

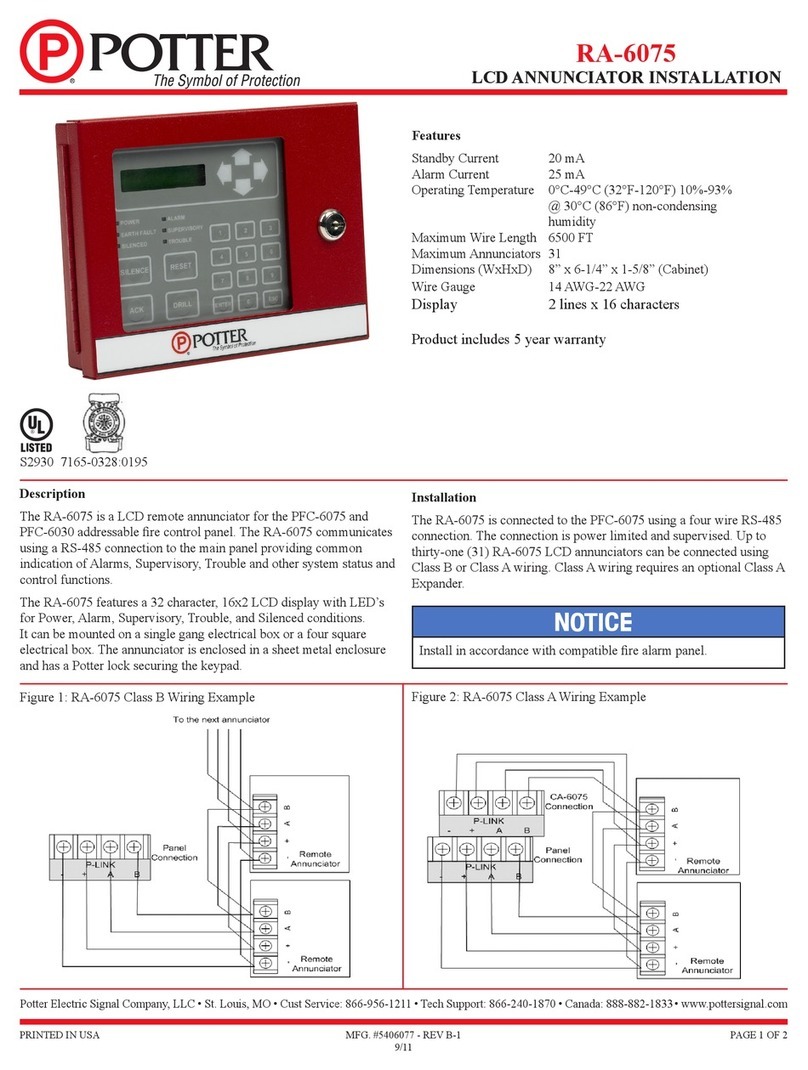

6. DIRECTION OF LOADING: Reusable Swivel Concrete Anchor can be

loaded in all ranges illustrated.

7. CONNECTION: Only one travel restraint, work positioning, fall arrest, or

rescue system may be attached.

8. EXTREME TEMPERATURE: The Reusable Swivel Concrete Anchor

is designed to be used in temperatures ranging from -30°F to +130°F

(-34°C to +54°C). Protection should be provided when used near welding,

metal cutting or similar activities. Contact Werner Co. with any questions

concerning extreme temperature environments.

180°

360°

LOAD LOAD

ACCEPTABLE ACCEPTABLE

126982-01 ©2022 Werner Co. Rev A

WernerCo Corporate Headquarters: 555 Pierce Road, Suite 300, Itasca, IL 60143

TEL: 888-523-3371 FAX: (888) 456-8459 www.wernerco.com

9. ELECTRICAL HAZARDS: Use extreme caution when working near high

voltage power lines due to the possibility of electric current owing through

the Reusable Swivel Concrete Anchor or connecting components.

10. RESCUE: In the event of a fall over the edge, special rescue measures

may be required. A rescue plan must be in place.

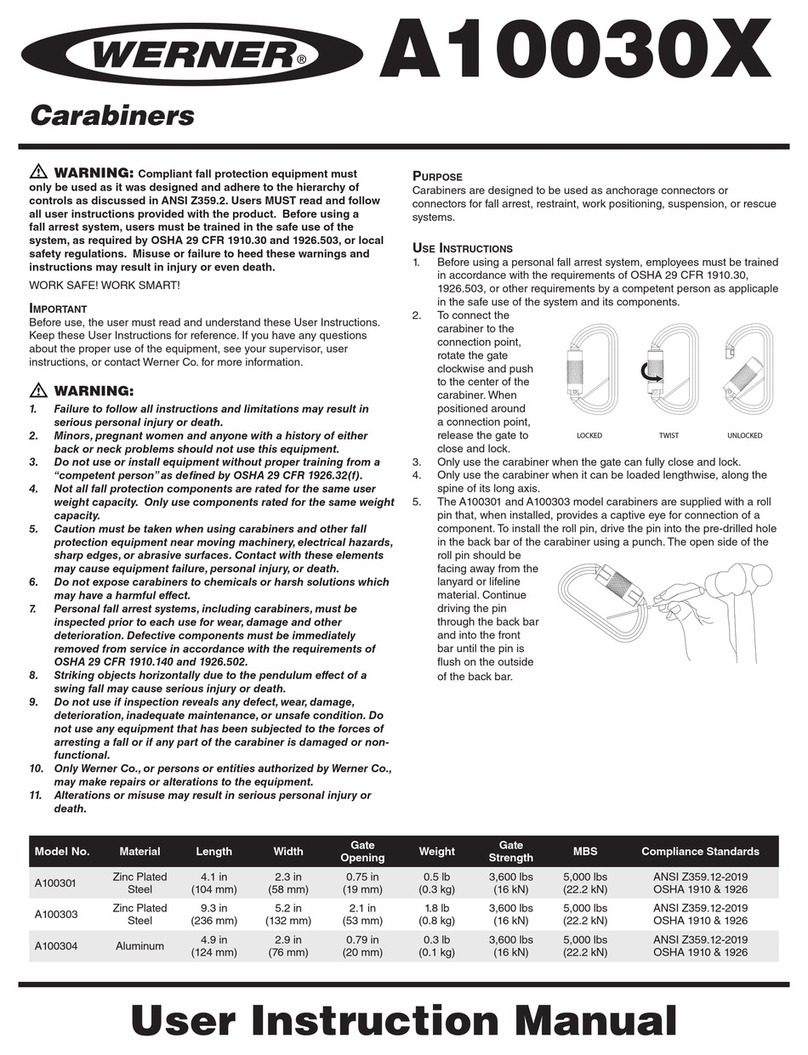

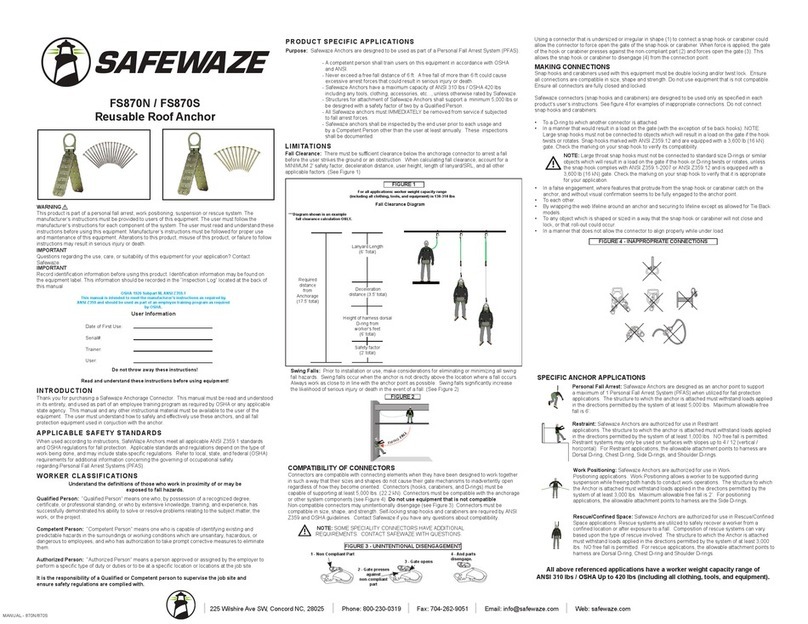

compatIbILIty LImItatIons

All connecting subsystems must only be coupled to compatible connectors.

OSHA 29 CFR 1910.140 and 1926.502 prohibit snap hooks from being engaged

to certain objects unless two requirements are met: snap hook must be a locking

type and must be “designed for” making such a connection. Under OSHA

“designed for” means that the manufacturer of the snap hook specically

designed the snap hook to be used to connect to the equipment in question.

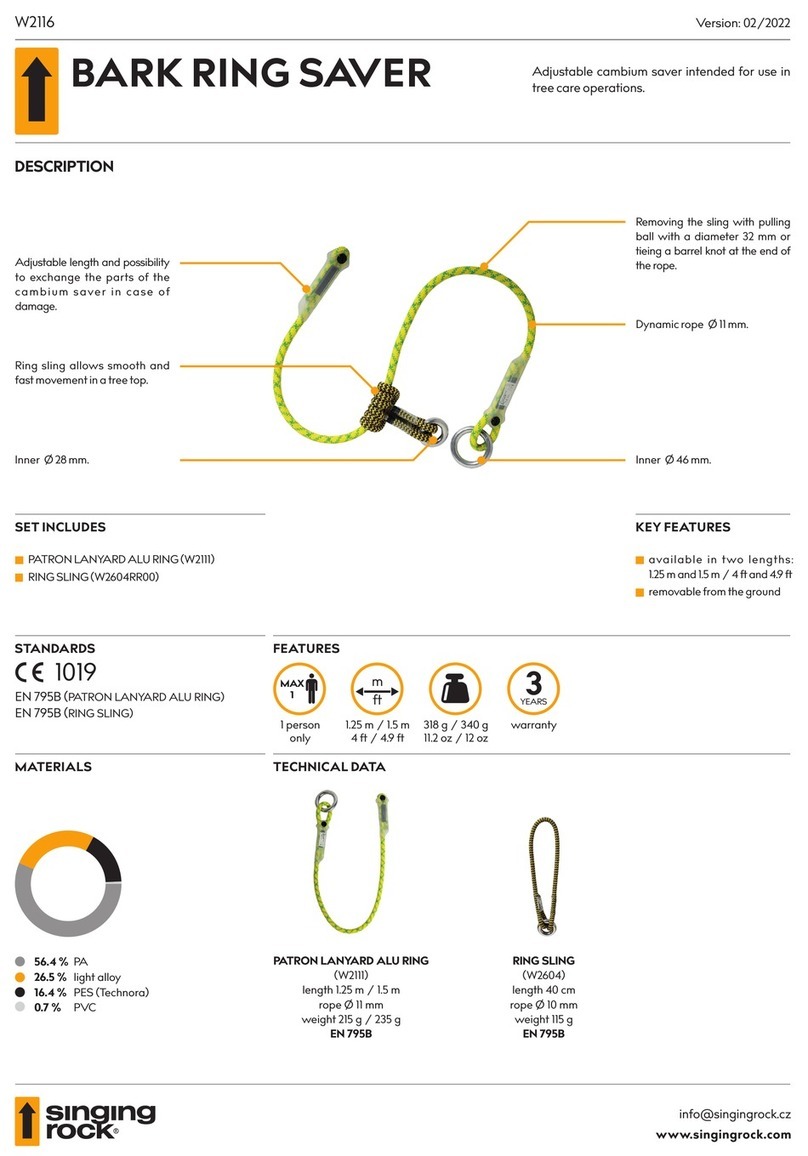

The following connections must be avoided because they can result in rollout*

when a non-locking snap hook is used:

• Direct connection of a snap hook to horizontal lifeline.

• Two (or more) snap hooks connected to one D-ring.

• Two snap hooks connected to each other.

• A snap hook connected back on its integral lanyard.

• A snap hook connected to a webbing loop or webbing lanyard.

• Improper dimensions of the D-ring, rebar, or other connection point in

relation to the snap hook dimensions that would allow the snap hook

keeper to be depressed by a turning motion of the snap hook.

*Rollout: A process by which a snap hook or carabiner unintentionally

disengages from another connector or object to which it is coupled.

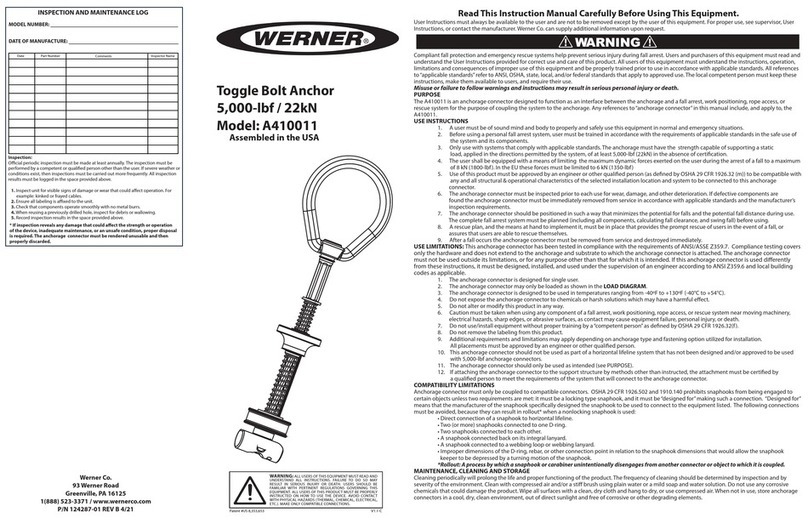

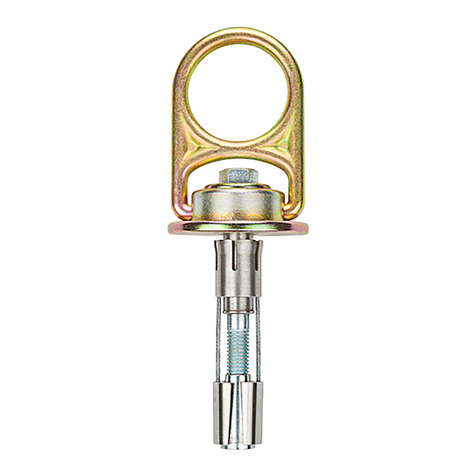

InstaLLatIon

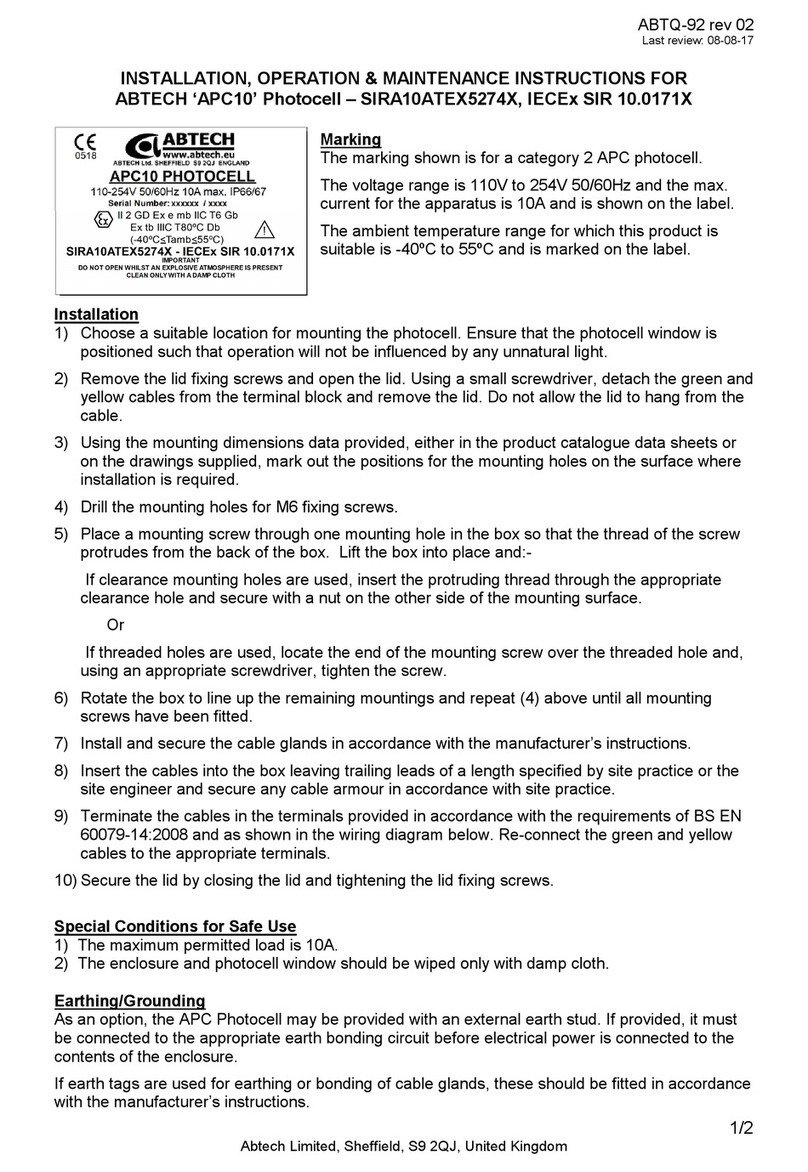

1. Drill a 3/4 inch diameter hole at least 3.5 inches deep. The drilled hole

must be straight and perpendicular to the surface. Make sure the hole is of

uniform diameter and free of peaks and valleys on the inner wall.

2. Blow hole clean with compressed air.

3. Always inspect the hole carefully when reusing a previously drilled hole.

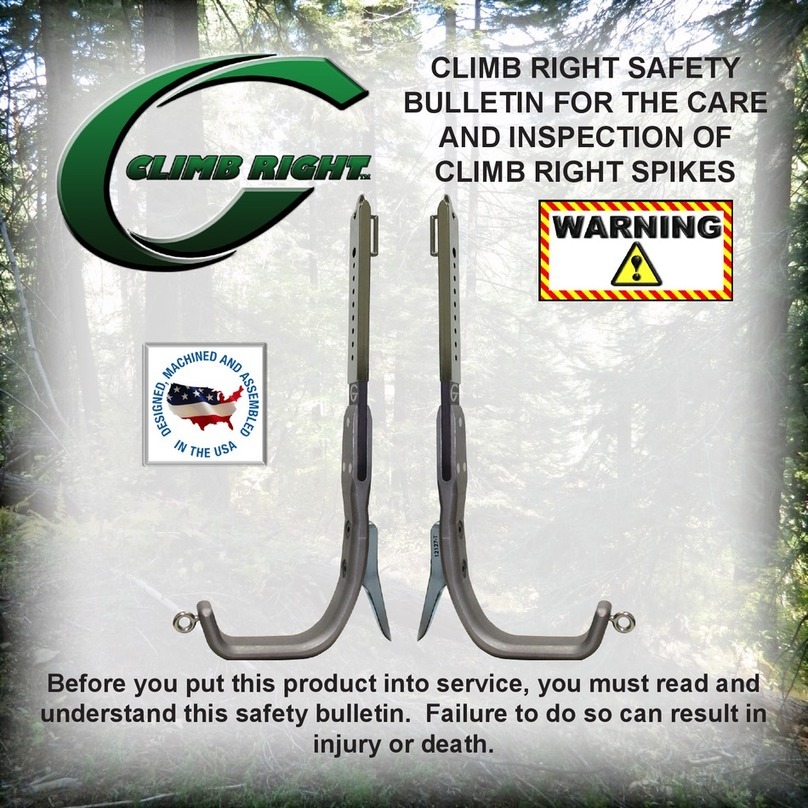

4. When placing anchor, place your thumb on the button and your rst two

ngers around the stop sleeve.

5. Squeeze your ngers and thumb together and compress the stop sleeve

and button together.

6. You should feel spring tension when compressing.

Remove the Reusable Swivel Concrete Anchor from

service if the spring is worn and does not separate

the stop sleeve and button when released.

7. Insert the anchor so the bottom of the stop sleeve is

ush with the surface of the concrete. Do not force.

8. Set the unit by tugging upward on the connecting

D-ring. Tugging upward will set the inner shaft into

the spoons and hold by pressing the spoons against

the wall of the hole.

9. After unit is set, pull rmly on the connecting D-ring. The unit should hold

tight and not move. If movement is felt, remove the anchor from the hole

and inspect the function and condition of the unit and the specication of

the hole.

removaL

1. When removing anchor, place your thumb on the

button and your ngers around the stop sleeve.

2. Squeeze your ngers and thumb together and

compress the stop sleeve and button together.

3. While compressing, pull the anchor out of the

hole.

4. If the anchor is stuck, lightly tap the button with

a hammer. Striking the anchor with force is not

necessary. A light tap is enough to disengage

the inner shaft from the spoons.

5. If the hammer was required to remove the anchorage connector, inspect

the anchorage connector thoroughly for damage after removal. If damage is

found remove from service and destroy immediately.

InspectIon

All components of the Reusable Swivel Concrete Anchor must be inspected

prior to each use and annually by an OSHA dened competent person other

than the user. Local, state, governmental and jurisdictional agencies governing

occupational safety may require the user to conduct more frequent or mandatory

inspections.

WARNING: If inspection reveals any defect, inadequate

maintenance, or unsafe condition, remove from service until a competent

person, as dened by OSHA 29 CFR 1910.140(b) and 1926.32(f), can

determine the need for authorized repair or disposal.

WARNING: Any equipment that has been subjected to the forces

of arresting a fall, or that has a deployed load indicator, must be removed

from service until a competent person can determine the need for

authorized repair or disposal.

All hardware must be free of cracks, sharp edges, deformation, corrosion, or any

evidence of defect. Reusable Swivel Concrete Anchor must be free of corrosion,

chemical attack, alteration, excessive heating or wear. All markings must be

legible and attached to the product.

cLeanIng and maIntenance

Reusable Swivel Concrete Anchor may be wiped down to remove grease or dirt

with a clean dry cloth.

LabeLs

Embedded on stop sleeve (ANSI Z359.18 Type A OSHA 1926.502 1910.140)

NO! NO! NO! NO!

NO!NO!NO!NO!

IncompatIbLe connectIons compatIbLe

connectIons

Reusable Swivel Concrete Anchor

(A) inch

min from any edge

(B)

inch

drill 3/4 inch Ø

6 in (15.3 cm)

12 in (30.5 cm)

12 in (30.5 cm)

5 in (12.7 cm)

HOLE DRILLING REQUIREMENT CHART

(A) Min. Edge/Corner distance (B) Concrete thickness

TAP!

Model No. Material Length Width Connection Size Minimum Breaking Strength

(MBS) Approx. Weight Compliance Standards

A510300 Stainless Steel

Nylon

7.5 in

(19.1 cm)

2.68 in

(6.8 cm)

2 in

(5.1 cm)

5,000 lb

(22.2 kN)

.70 lb

(0.35 kg)

ANSI Z359.18-2017 Type A

OSHA 1910 & 1926

Scan for more Information

P/N126962-02 REV A

1 user MAX

-30 to + 130 F

-34 to + 54 C

Other Werner Safety Equipment manuals

Werner

Werner A330000 Operator's manual

Werner

Werner A320013 Guide

Werner

Werner Bantam 6 User manual

Werner

Werner A570000 User manual

Werner

Werner UPGEAR L242 Series User manual

Werner

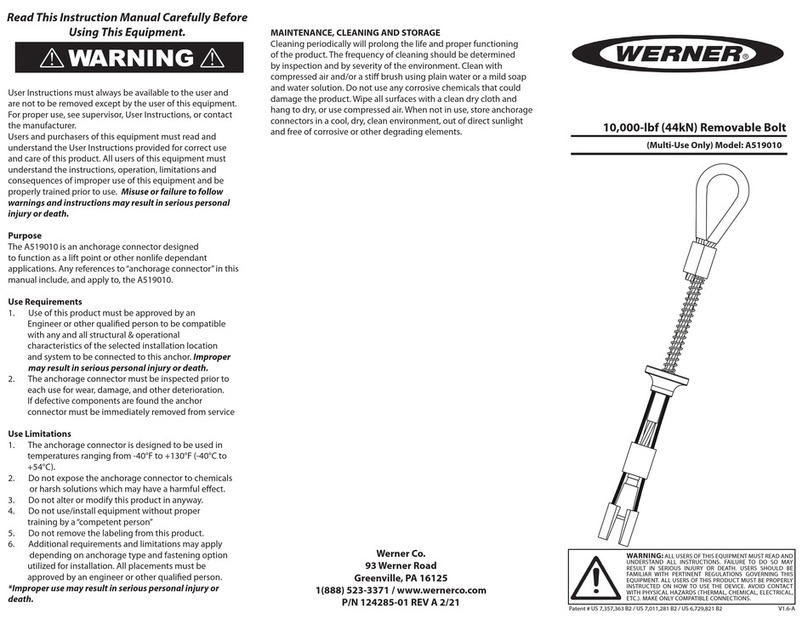

Werner A519010 User manual

Werner

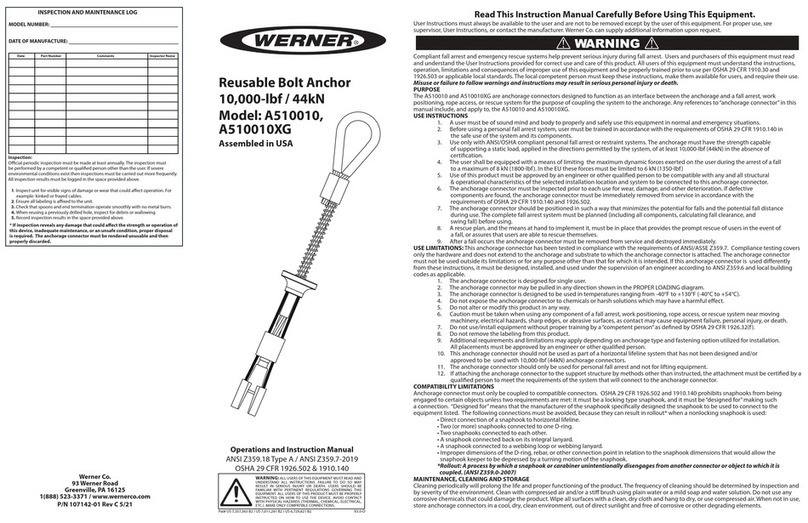

Werner A510010 User manual

Werner

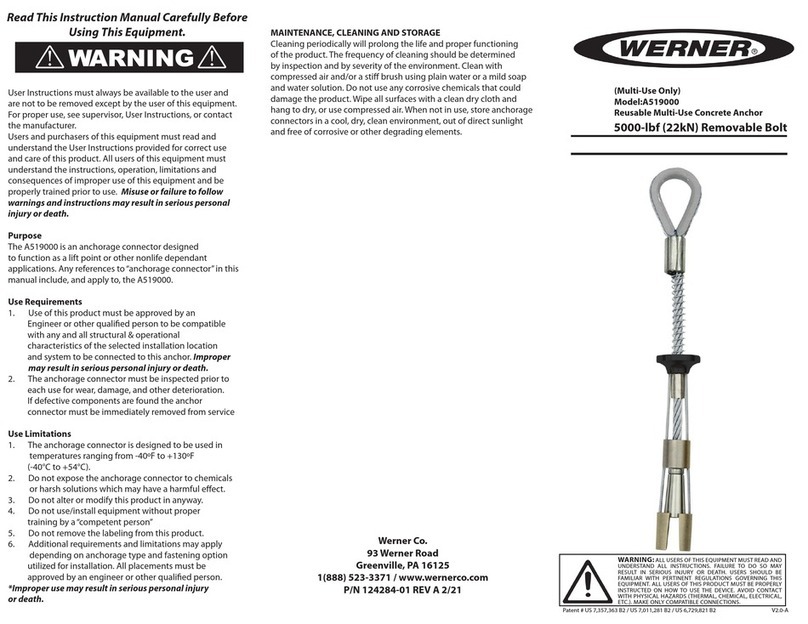

Werner A519000 User manual

Werner

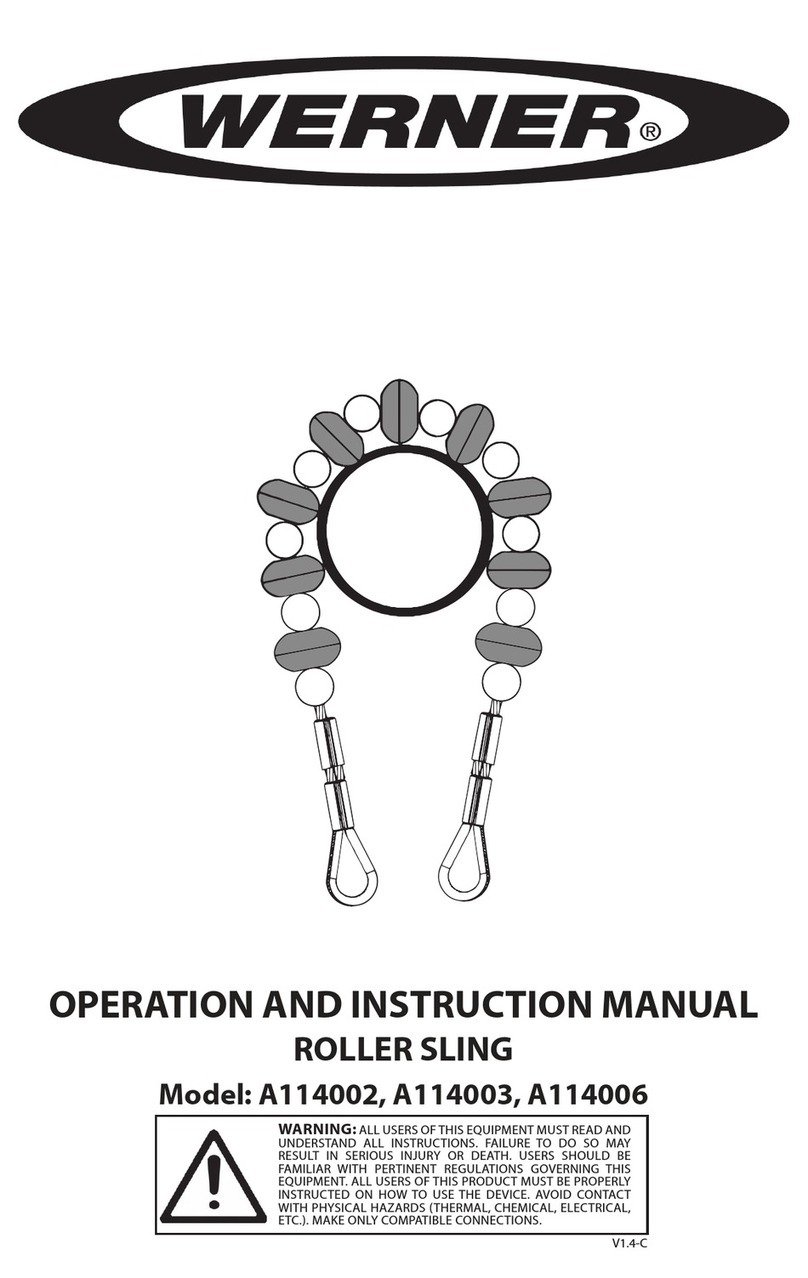

Werner A114002 Guide

Werner

Werner A510024 User manual

Werner

Werner A410400 Guide

Werner

Werner A550000 User manual

Werner

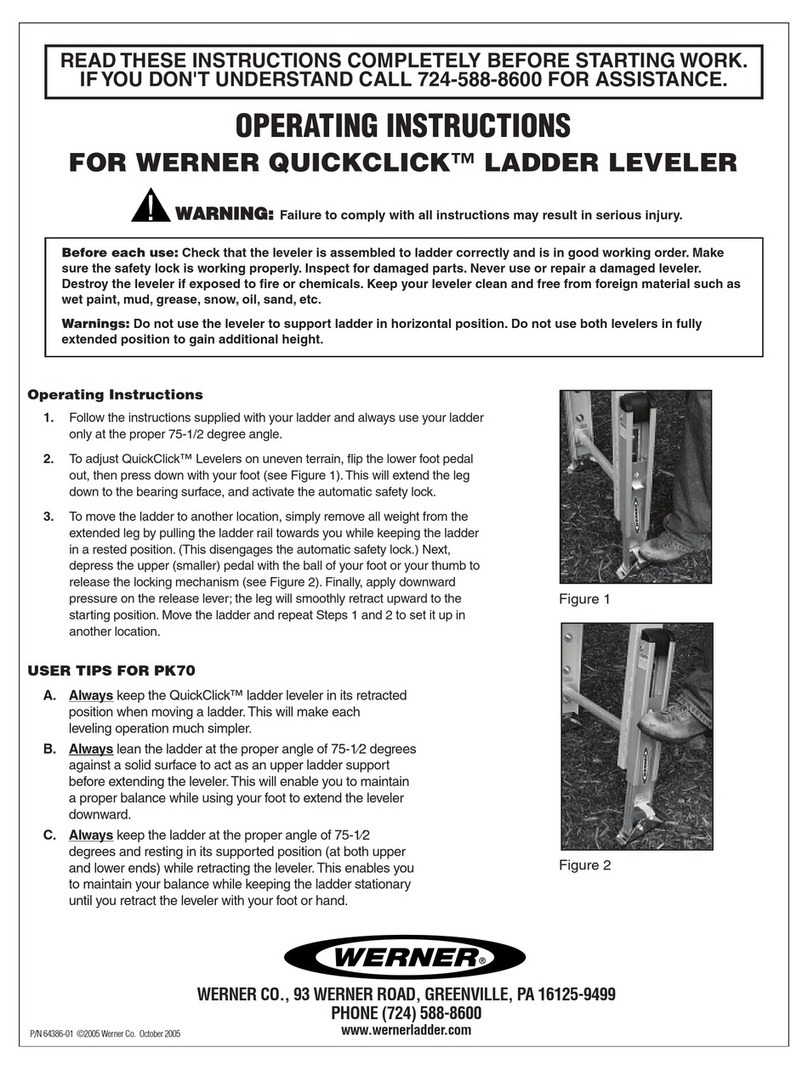

Werner QUICKCLICK User manual

Werner

Werner KNAACK User manual

Werner

Werner MAX PATROL R410020 User manual

Werner

Werner A510002 Guide

Werner

Werner A510003 User manual

Werner

Werner A410000 Guide

Werner

Werner A550000 User manual

Werner

Werner L242350CA Series User manual