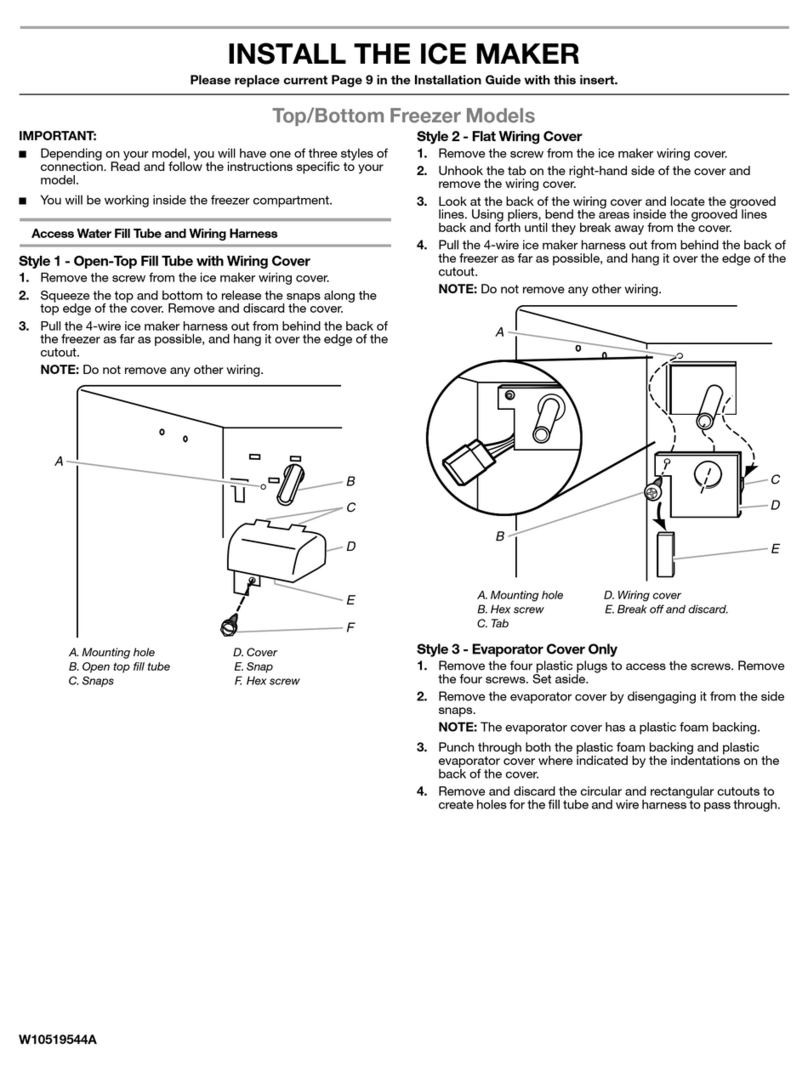

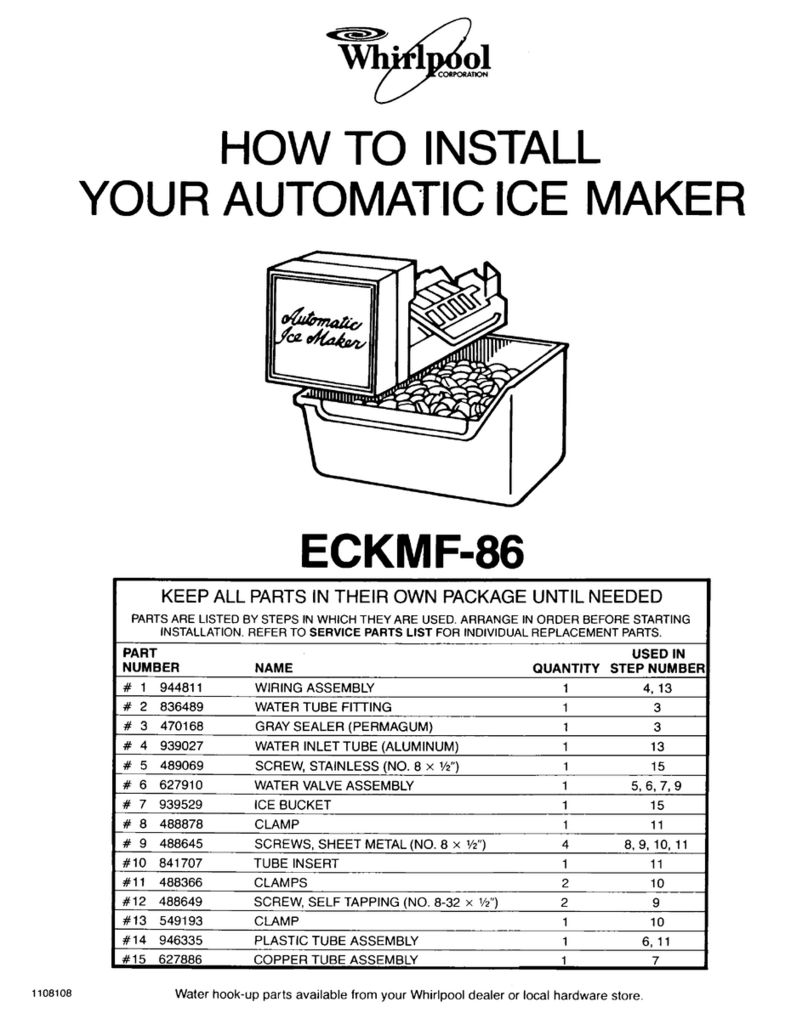

NOTE: Always purge the water line before making

the final connection to the inlet tube to prevent

possible water valve malfunction.

After the cabinet is in place, bend the tubing to

meet the connection at the water valve. This joint

provides a convenient disconnect for service. Be

sure the tubing is clear of compressor, to prevent

rattle. 2 5

RIGHT END VIEW BACK VIEW

CABINET

5.35 mm 0.0. WATER

LINE COMPRESSION

FllTlNG AT

WATER INLET

VALVE

1

HOLE FOR FIELD

5”PPlEO WATER

WATER LINE TO CONNECT

TO WATER VALVE FIlTING mm

4

FIGURE 1

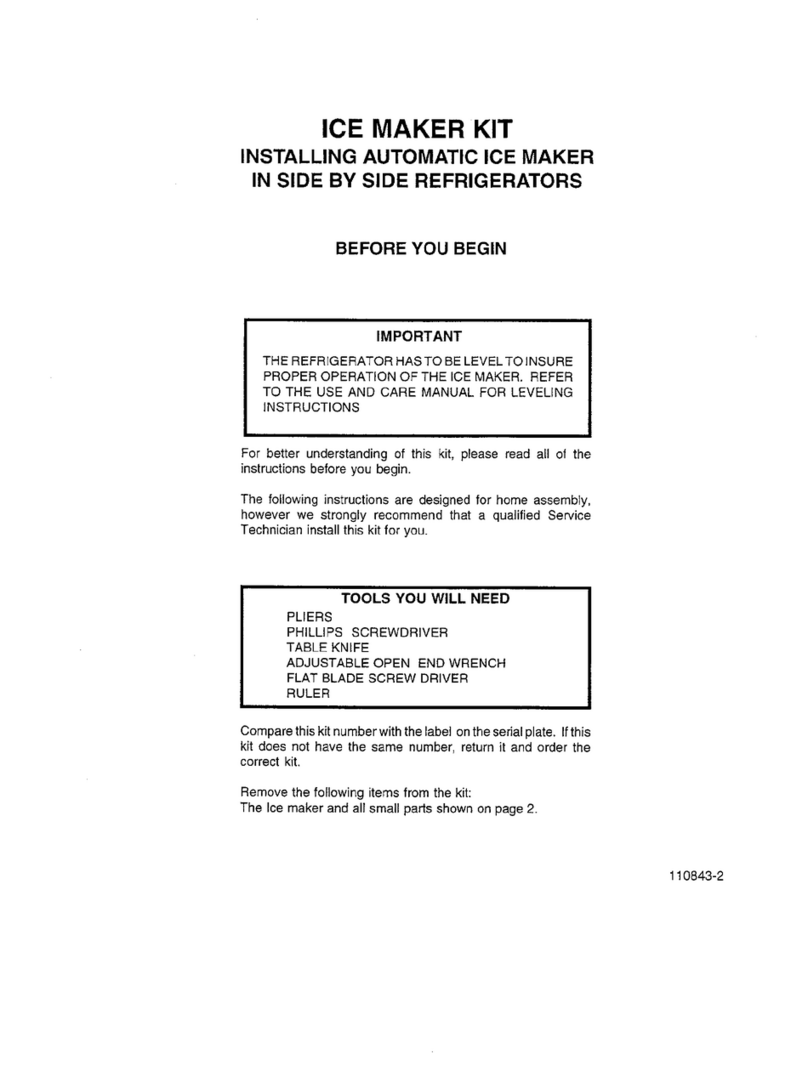

CONNECT THE DRAIN

1.

2.

3.

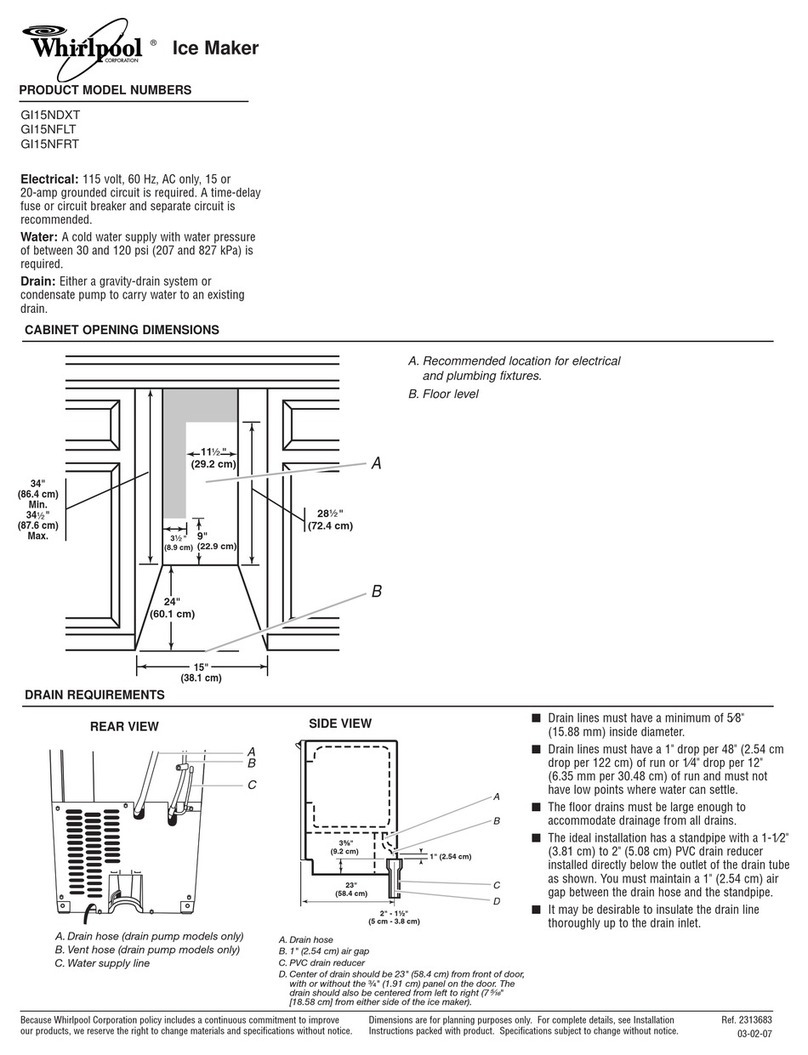

The unit is provided with a gravity drain.

The ideal installation has a standpipe (32 mm,l%”

minimum) installed directly below the outlet of the

drain tube.

It may be desirable to insulate drain line

thoroughly up to drain inlet.

SUMP PUMP

1. When a drain connection below the level of the unit

is not available, a sump pump may be used to lift the

water to an available drain.

2. Pumps of approved design for operation on 220/240

Volt, 50 Hz current may be purchased locally.

3. Install sump pump on floor behind ice maker with

discharge tube to the rear. Run bin drain directly to

sump pump as shown in the illustration.

1

SVMP PUMP HAS FLOAT

SWlTCnTHATCYCLES 2

A00 PLASTIC HOSE

3

FIELDSUPPLIED

WATER LINE

THRU THIS HOLE

NOTE: Electric connection to sump pump should

be from a circuit that remains energized continually.

FOR THE ELECTRICIAN

ELECTRICAL REQUIREMENTS

A 220/240 Volt, 50 Hz, 10 Amp fused electrical supply is

required (time delay fuse or circuit breaker is recom-

mended). It is recommended that a separate circuit,

serving only this appliance be provided.

ELECTRICAL GROUND IS REQUIRED ON

THIS MACHINE

GROUNDING

For your personal safety permanently ground this unit

in accordance with applicable local codes and ordi-

nances. It is recdmmended that a separate, permanent

ground connection be made to the unit using a green/

yellow colored, insulated conductor of appropriate size

from a grounded cold water pipe*, a grounded lead in

the service panel or a properly driven and electrically

grounded ground rod. Do not ground to a gas supply

pipe. Do not connect to electric power supply until unit

is permanently grounded. Connect the ground wire to

the approved ground and then connect to the metal

frame of the unit.

‘Cold water pipe must have metal continuity to electrical ground

and not be interrupted by plastic. rubber, or other electrically

insulating connectors (including water meter or pump) without

adding a jumper wire at these connections.

WIRING

CONFORM TO ALL LOCAL CODES

AND ORDINANCES

Remove grill mounting screws for access to motor com-

partment and water connections. Electrical connec-

ticns are made to the electrical box which is located at

the rear of the machine. Run permanent type 1.6 mm +

(# 14) wiring through the hole provided in the electrical

box to the line screws on the terminal board. (See figure

2 next page.)