4

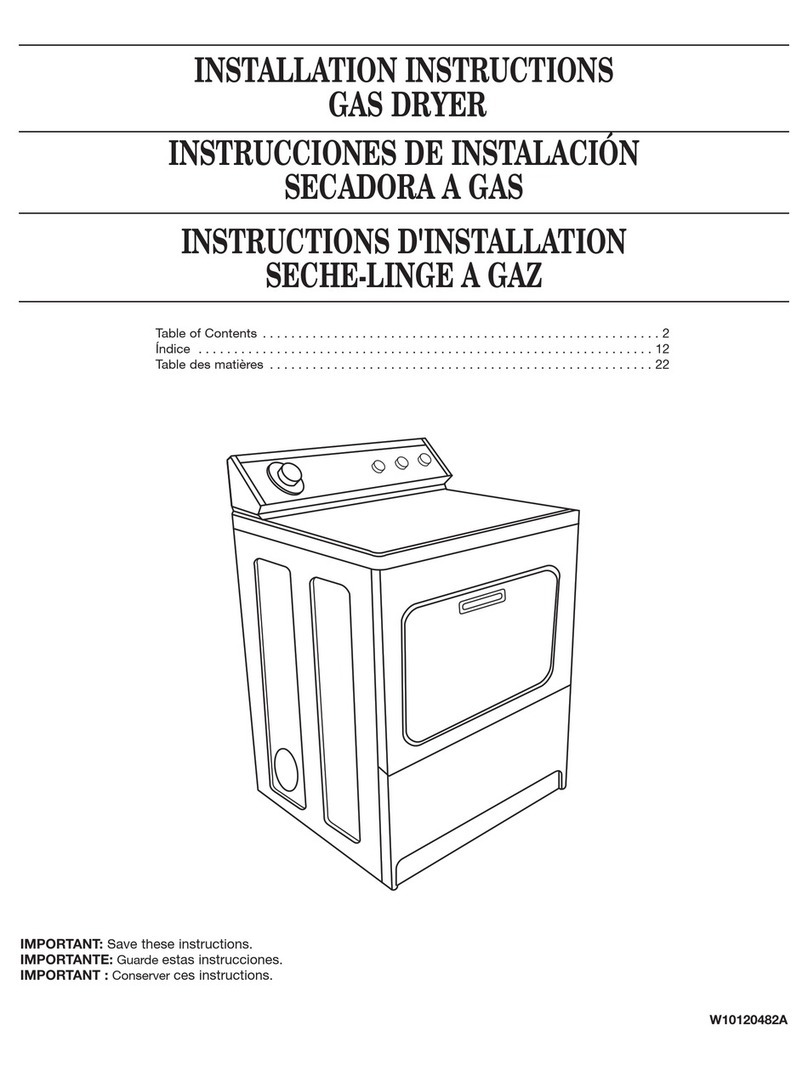

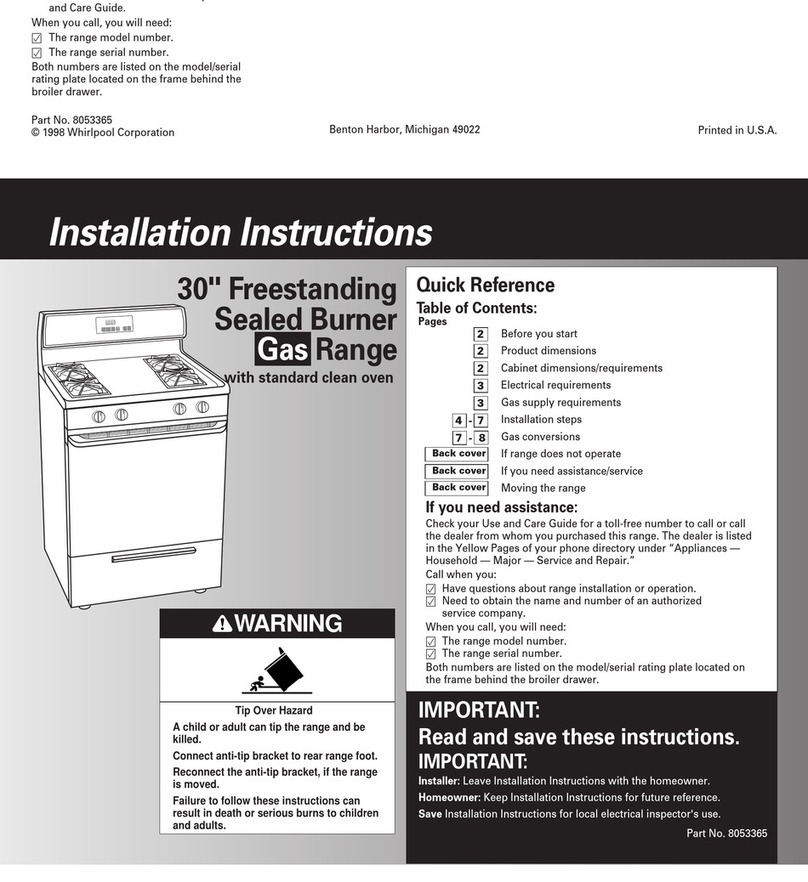

Electrical requirements

Gas supply

requirements

Recommended

ground method

For personal safety, this range is

equipped with a power supply cord

having a 3 prong ground plug. To

minimize possible shock hazard, the cord

must be plugged into a mating 3 prong,

ground-type outlet, grounded in

accordance with the National Electrical

Code, ANSI/NFPA 70 — latest edition*

and all local codes and ordinances.

If a mating outlet is not available, it is the

personal responsibility and obligation of

the customer to have a properly polarized

and grounded, 3 prong outlet installed by

a qualified electrician.

If codes permit and a separate ground

wire is used, it is recommended that a

qualified electrician determine that the

ground path is adequate.

Do not ground to a gas pipe.

Check with a qualified electrician if you

are not sure range is properly grounded.

A 120-volt, 60-Hz, AC-only, 10 amp, fused

electrical supply is required. A time-delay

fuse or circuit breaker is recommended. It

is recommended that a separate circuit

serving only this appliance be provided.

Electronic ignition systems operate within

wide voltage limits, but proper grounding

and polarity are necessary. In addition to

checking that the outlet is correctly

grounded, the outlet must be checked by

a qualified electrician to see if it is wired

with correct polarity.

IMPORTANT: This range is equipped with

an electronic ignition system that will not

operate if plugged into an outlet that is

not properly polarized.

A wiring diagram is included on the back

of the range.

See “Cutout dimensions/requirements”

section for recommended location of

electrical outlet.

3 prong

polarized

ground-type

outlet

3 prong ground

plug

ground

prong

power

supply

cord

Observe all governing codes and

ordinances.

This installation must conform with all

local codes and ordinances. In the

absence of local codes, installation must

conform with American National

Standard, National Fuel Gas Code ANSI

Z223.1 — latest edition**.

Input ratings shown on the model/serial

rating plate are for elevations up to 2,000

feet. For assistance when installing the

range at higher elevations, contact your

local service company.

Type of gas: This range is design-certified

by CSA International for use with L.P. gas

or, after proper conversion, for use with

Natural gas.This range is factory set for

use with L.P. gas. Gas conversion

instructions are provided on pages 8–9.

The model/serial rating plate located on

the frame behind the broiler drawer has

information on the type of gas that can

be used. If the type of gas listed does not

agree with the type of gas available,

check with the local gas supplier.

Conversion must be done by a qualified

service technician.

Gas supply line: Provide a gas supply line

of 3/4" rigid pipe to the range location.

With L.P. gas, piping or tubing size can be

1/2" minimum. A smaller size pipe on

longer runs may result in insufficient gas

supply. Usually, L.P. gas suppliers

determine the size and materials used in

the system.

Pipe-joint compounds made for use

with L.P. gas must be used on pipe

threads only.

Copies of the standards listed may be

obtained from:

*National Fire Protection Association

One Batterymarch Park

Quincy, Massachusetts, 02269

**CSA International

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

In the State of Massachusetts, the

following installation instructions

apply:

• Installations and repairs must be

performed by a qualified or

licensed contractor, plumber, or

gasfitter qualified or licensed by

the State of Massachusetts.

• If using a ball valve, it shall be a

T-handle type.

• A flexible gas connector, when

used, must not exceed 3 feet.