CAUTION

To prevent electrical shock and/or equipment damage,

disconnect electric power system at main fuse or

circuit breaker box until installation is complete.

This control is not intended for use in locations where

it may come in direct contact with water. Suitable

protection must be provided to shield the control from

exposure to water (dripping, spraying, rain, etc.).

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and

dangerous operation.

Following installation or replacement, follow appliance

manufacturers’ recommended installation/service

instructions to insure proper operation.

Do not exceed specified voltage of circuits. Higher

voltage will damage control and could cause shock or

fire hazard.

CAUTION

Application of this type of control may cause flame

rollout on initial startup and could cause personal

injury and/or property damage.

Replace only with exact model number, including

dash number. Failure to use exact replacement control

could cause personal injury and/or property damage.

Do not short out terminals on gas valve or primary

control to test. Short or incorrect wiring will damage

the comfort control and could cause personal injury

and/or property damage.

11E79

INTEGRATED WATER

HEATER CONTROL

INSTALLATION INSTRUCTIONS

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY BEFORE

INSTALLING OR OPERATING THIS CONTROL COULD CAUSE PERSONAL

INJURY AND/OR PROPERTY DAMAGE.

PRECAUTIONS

DESCRIPTION

FIRE, SHOCK AND EXPLOSION HAZARDS

• Shutoffmaingastoapplianceforserviceoruntil

installation is complete.

• Disconnectelectricpowerbeforeservicing.

• Donotexceedthespeciedvoltage.

• Replacethiscontrolwithonlytheexactmodelnum-

ber listed above.

• Protectthecontrolfromdirectcontactwithwater

(dripping, spraying, rain, etc.)

• Ifthecontrolhasbeenindirectcontactwithwater,

replace the control.

• Labelallwiresbeforedisconnectionwhenservic-

ing controls.Wiring errors can cause improper and

dangerous operation.

• Routeandsecurewiringawayfromame.

• Ensureproperearthgroundingofappliance.

• Ensureproperconnectionoflineneutralandline

hot wires.

• Donottakecontrolapart,therearenoserviceable

parts inside.

• Donotusecontrolifithasbeenooded.

• Neverstandonthecontroloruseasastep.

PART NO. 37-7512A

1403

www.white-rodgers.com

www.emersonclimate.com

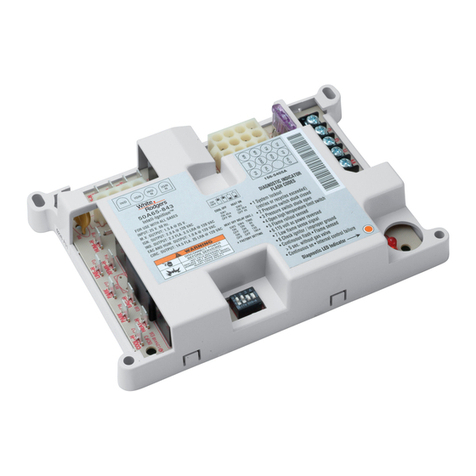

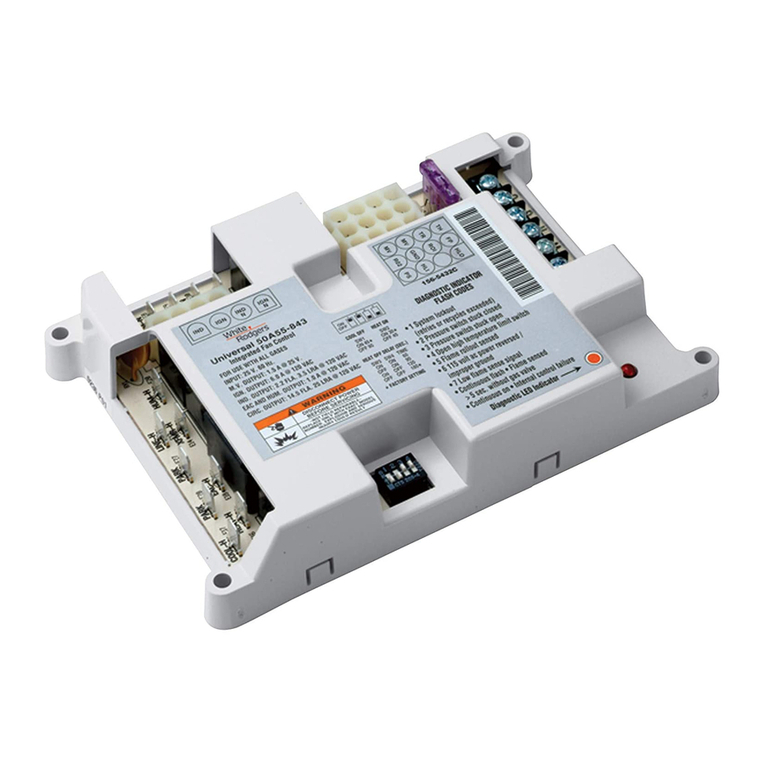

The 11E79 control is a solid-state thermostat control for

gas fired commercial water heater applications. The 11E79

supplies a relay switched output for damper or inducer

fan applications, and a “Call for Heat” signal or power to

energize a gas valve. The 11E79 receives input signals from

a temperature probe and Electrical Cutoff (ECO). It controls

temperature with an integrated temperature control knob. The

diagnostic features of the 11E79 make is easy to diagnose

system faults and issues.

Replace a 11E79-XXX control with an approved model

number as indicated on the cross reference table below:

11E79 Model Number Replacement Cross Reference Table

OEM Model Approved Replacement Temperature Range

11E79-101 11E79-901 120°F to 180°F

11E79-301 11E79-901 120°F to 180°F

11E79-400 None 120°F to 185°F