WHITEHALL MANUFACTURING • P.O. BOX 3527 • City of Industry, CA 91744-0527 U.S.A

Phone (800) 782-7706 • (626) 968-6681 • Fax (626) 855-4862 • Web: www.whitehallmfg.com

6

Instructions for Operation and Care of Water Bath SP-1600-D-220

I filled my Water Bath with water to the prescribed

water level, plugged it in, turned it "ON" (power switch

is illuminated), and the Temperature Controller display

is illuminated but the unit is not heating up the water.

If the appliance is operated without water, the concealed

heating element may be subjected to damage and may

no longer heat up the tank even though power is "ON". If

heating element becomes damaged, it will have to be

replaced.

--------------------------------------

I filled my Water Bath with water, plugged it in, turned

it "ON" (power switch and Temperature Controller

display are not illuminated) and the unit is not heating

up the water.

Mains circuit breaker may have "tripped". Reset the

Power Mains circuit breaker. Plug in the Water Bath to a

G.F.C.I. protected electrical receptacle. Do not plug in

any other devices or appliances to the same receptacle

the Water Bath is using.

Equipment Circuit Protection fuse(s) may have "blown".

Check fuse(s) for electrical continuity using a Multi-Meter

(Comb. Volt, Ampere, & Ohm meter). Replace fuse(s) if

necessary. Be sure to use the correct fuse size & type.

Refer to the Repair Parts section of the manual.

Electrical component(s) such as power inlet, fuse

holders, fuse carriers, power switch, quick disconnect

terminals, wire connectors, wiring, etc. may have

become faulty. A qualified electrical technician should

perform an electrical continuity inspection of the entire

electrical system using a Multi-Meter to identify possibly

bad electrical component(s). Replace electrical

component(s) as required.

--------------------------------------

My Water Bath was "ON" because the Power Switch &

Temperature Controller were illuminated "ON". The

water level inside tank went very low (nearly empty) or

evaporated out completely from the appliance. The

appliance turned "OFF" on its own and cannot be

switched "ON" at the power switch.

The Water Bath is provided with an Over-Heating

Temperature Limiting Sensor as a safety feature. If the

operating thermostat fails the temperature will rise.

When a temperature of 215°F (102°C) is achieved the

over-temp thermostat will open the circuit and the

temperature will drop to 180°F (82°C), then rise again.

This cycle will continue until the operating thermostat is

replaced.

The appliance will require a qualified technician to turn

over the unit; carefully remove the bottom cover by

removing the mounting screws. The technician will

troubleshoot and/or replace the operating thermostat.

The heating element should be visually and electrically

inspected to ensure that it is still in good, proper working

condition. Make sure the heating element did not

delaminate from the underside of the tank. Make sure

the heating element still has electrical continuity by

checking circuit with a Multi-Meter. Check that the

heating element does not have dark discolored spots,

which may indicate that the element has burned.

Before reassembling, be sure to perform a visual and

electrical inspection on the rest of the electrical system.

Make certain all other electrical components are in good,

working condition. Replace any components that appear

to be burned or have become faulty.

--------------------------------------

How do I know what temperature to set the

Temperature Controller to?

Refer to splint material manufacturer for recommended

temperature & duration of splint material used.

--------------------------------------

How long will it take for my Water Bath to reach the

set point temperature?

Allow 60 to 75 minutes for the appliance to reach set

point temperature. Keep lid closed to ensure quickest

heat-up and to maintain set point temperature.

--------------------------------------

How do I know if/when my Water Bath has reached set

point temperature?

The numerical value displayed on the controller display

will be the same as the set point temperature or very

near to the set point temperature. Please allow +/- 3º F

temperature variance.

--------------------------------------

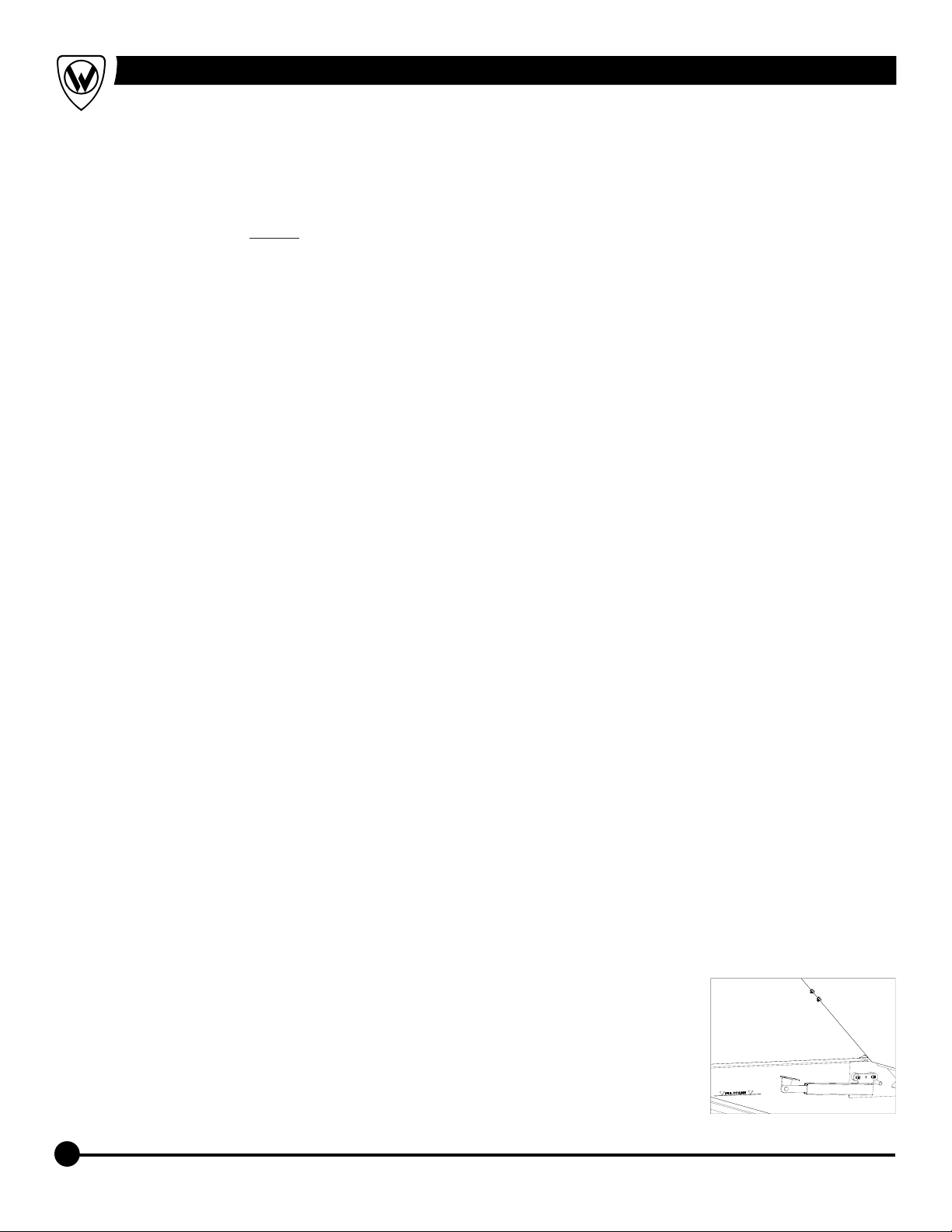

How do I open the lid more than 90º?

Make sure unit is unplugged and all water is drained

from the tank. Take an adjustable wrench and

screwdriver and remove the 2 screws and nuts from the

lid stay on the underside of the lid. Remove the lid stay

and reinstall the screws and nuts in the lid. Follow this

procedure for both sides.

Remove the hinge stays from the pins located in the

tank. Make sure to reinsert the screws.

FAQs (Frequently Asked Questions) & TROUBLESHOOTING

This will allow the lid to

past 90º and keep the lid in

an upright position. Please

keep these parts as they can

be used to reassemble the

lid stays to the lid if a partially

open lid is again warranted.

open