MK 1R

3

I. PRELIMINARY.......................................................................................................................................4

I.1 General description ........................................................................................................................4

I.2 TOOLS NEEDED FOR FITTING....................................................................................................6

II. PREPARATION..................................................................................................................................6

II.1 Unfitting the hardware FROM the mast..........................................................................................6

III. INSTALLATION..................................................................................................................................7

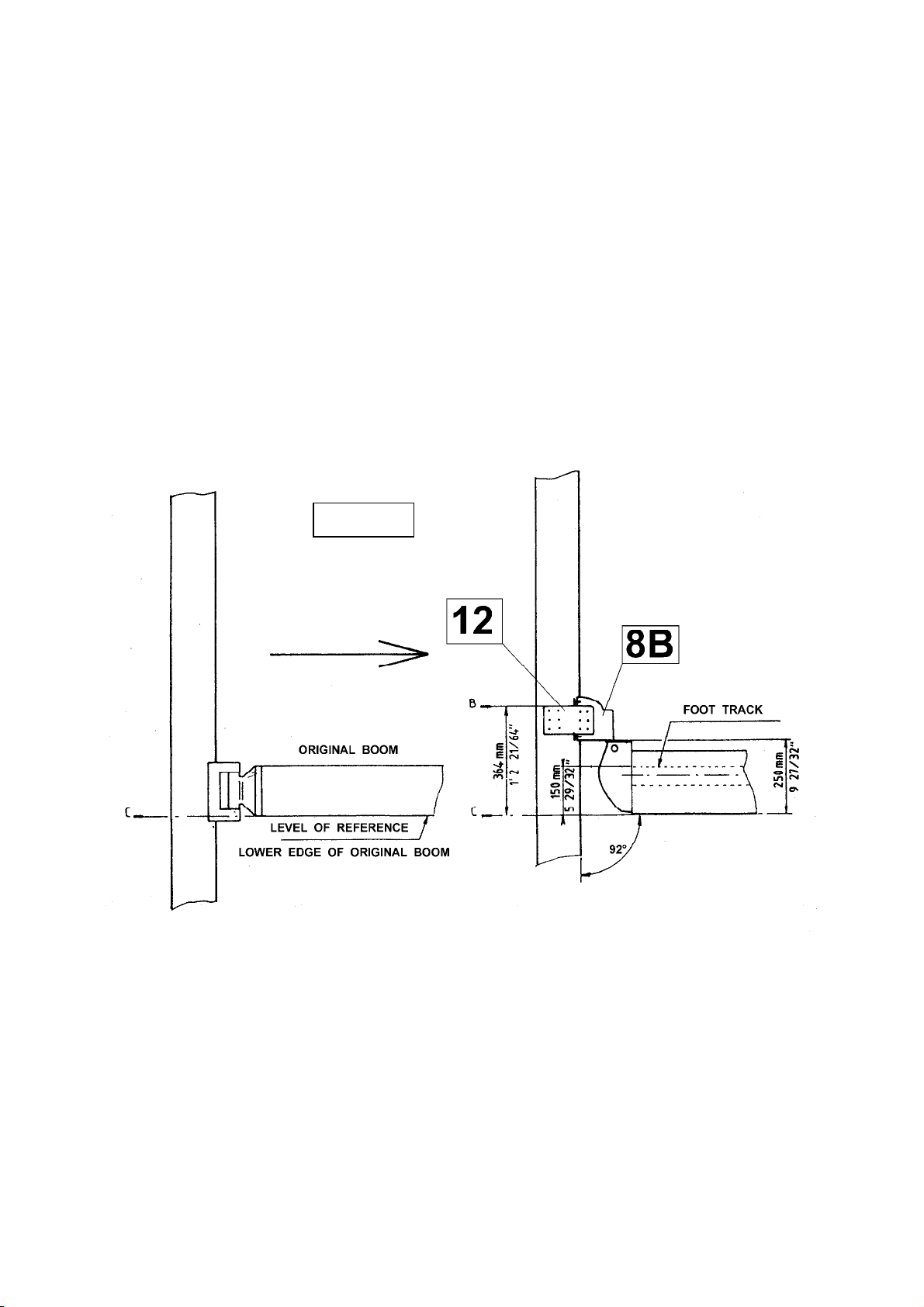

III.1 DETERMINING THE HEIGHT OF THE GOOSENECK................................................................7

III.2 FITTING THE SLIDE SCREWS INTO THE MAST TRACK........................................................... 7

III.3 FITTING THE GOOSENECK .........................................................................................................8

III.4 FITTING THE HALYARD SPREADER ..........................................................................................8

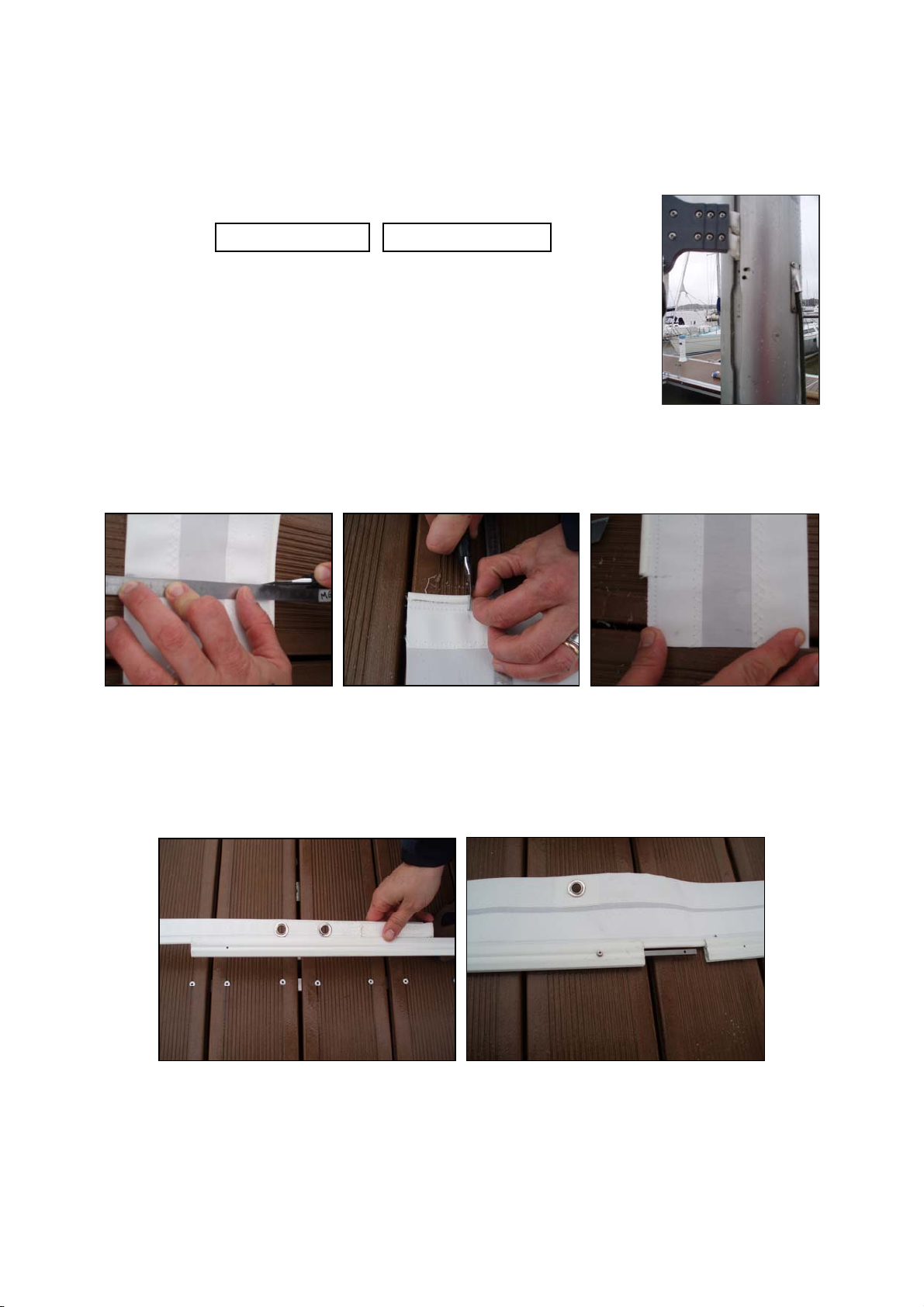

III.5 ASSEMBLING THE LUFF SECTION & LUFF TRIANGLE & FEEDER .........................................9

III.6 CUTTING THE BOOM SECTION AND THE MANDREL TO LENGTH.......................................14

III.6.A How to calculate the length of the boom SECTION..............................................................14

III.6.B Cutting the mandrel (11F) to length ......................................................................................16

III.6.C Fitting the mandrel onto the boom ........................................................................................16

III.7 Fitting the boom onto the gooseneck ...........................................................................................18

III.8 FITTING THE BOOMVANG HOUND AND THE BOOMVANG....................................................19

III.9 FITTING OF THE LUFF TRIANGLE ON THE MAST .................................................................. 20

III.10 ADJUSTING THE POSITION OF THE MAINSHEET BALES (1)............................................ 20

III.11 INSTALLATION OF THE CONTROL LINES TO THE COCKPIT ............................................21

IV. FITTING THE MAINSAIL .................................................................................................................22

V. ADJUSTMENT OF THE BOOMVANG ANGLE TO THE MAST......................................................24

VI. USING THE PROFURL IN-BOOM REEFING SYSTEM .................................................................24

VI.1 Rules of thumb : ...........................................................................................................................24

VI.2 LIMITS FOR USING THE SYSTEM IN RELATION WITH APPARENT WIND............................25

VII. WARRANTY.....................................................................................................................................26

VIII. MK1R SPARE PARTS LIST ............................................................................................................27

IX. MAINSAIL DESIGN SPECIFICATIONS................................................. 29

IX.1 GEOMETRY .................................................................................................................................29

IX.1.A Luff curve design ...................................................................................................................29

Luff curve: ............................................................................................................................................29

IX.1.B Foot curve design..................................................................................................................29

IX.1.C Roach ....................................................................................................................................29

IX.2 FINISH DESIGN ...........................................................................................................................29

IX.2.A Luff tape material...................................................................................................................29

IX.2.B Foot tape diameter ................................................................................................................30

IX.2.C Luff and foot TAPE diameter.................................................................................................30

IX.2.D battens...................................................................................................................................30

IX.2.E Clew tack and head assembly ..............................................................................................30

PRELIMINARY CAUTIONS

The PROFURL in-boom mainsail reefing system is not designed to be

installed on wooden masts, or aluminium masts with track added with

screws, rivets, glue or any similar assembly. Fitting on a carbon mast is not

recommended as it requires specialized knowledge and skills. Please

contact us.

Please check that there is no sign of corrosion on the mast which may

compromise the strength of the assembly.

The person in charge with fitting will be fully responsible for installation and

adaptation on board according to the specifications shown in this manual.