Kunststoffschweißtechnik

Contens

18.07.2013 Working Instructions WIDOS ESI 4000 Page 4 of 37

1. PRODUCT DESCRIPTION.............................................................................................. 6

1.1. Application and intended use..............................................................................................6

1.2. Safety measures ...................................................................................................................6

1.3. Conformity.............................................................................................................................6

1.4. Designation of product.........................................................................................................6

1.5. Technical data.......................................................................................................................7

1.6. Equipment..............................................................................................................................7

1.7. Wear parts .............................................................................................................................7

2. SAFETY RULES.............................................................................................................. 8

2.1. Explication of the different symbols...................................................................................8

2.2. Obligations of the operator..................................................................................................8

2.3. Obligations of the worker ....................................................................................................8

2.4. Structural modifications on the device ..............................................................................9

2.5. Dangers by electrical energy...............................................................................................9

2.6. Danger of stumbling over the connecting line ..................................................................9

2.7. Danger of combustion at the socket...................................................................................9

2.8. Danger by toxic vapors........................................................................................................9

2.9. Warranty and liability..........................................................................................................10

3. FUNCTIONAL DESCRIPTION ...................................................................................... 11

4. INDICATING AND OPERATING ELEMENTS .............................................................. 12

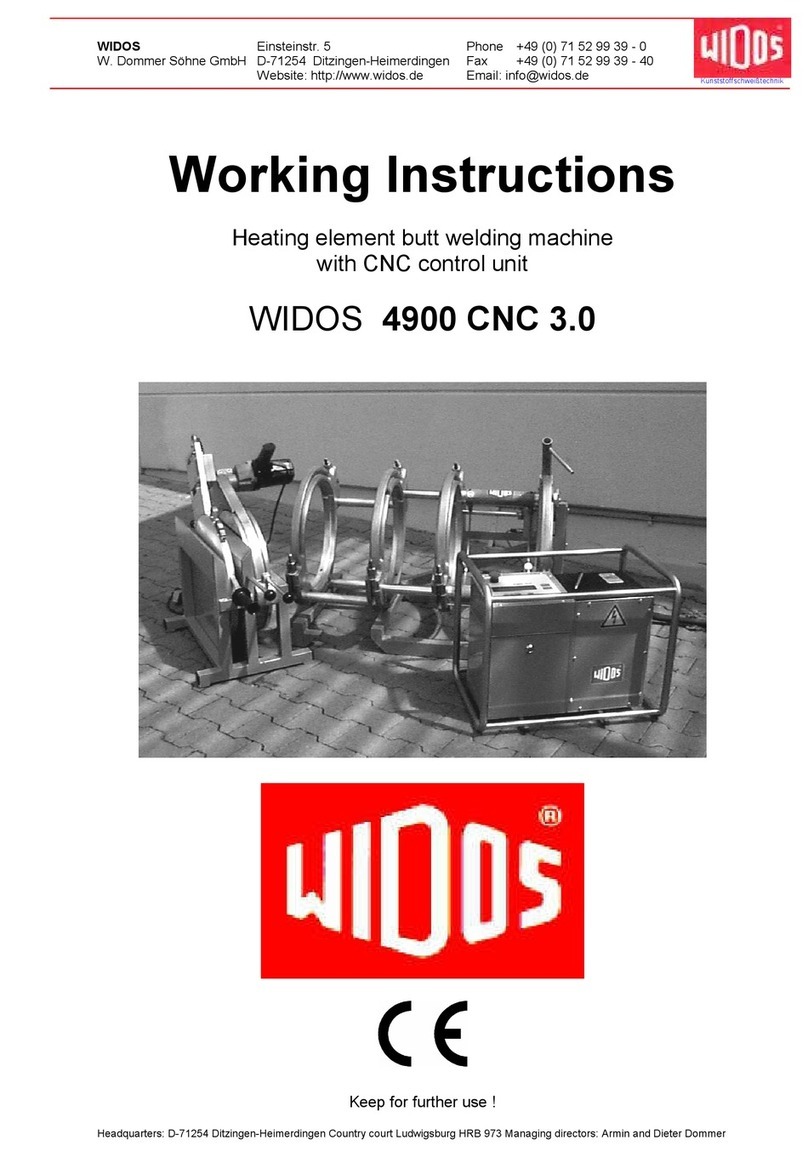

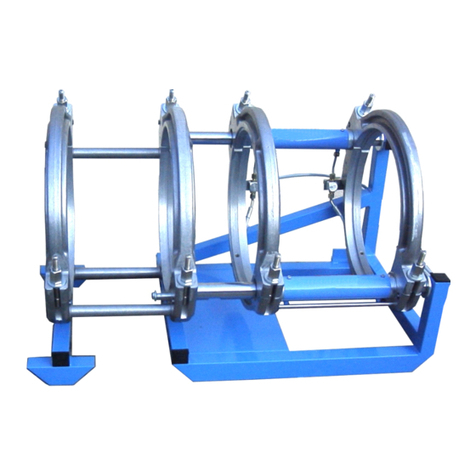

4.1. Overview device..................................................................................................................12

4.2. Welding device....................................................................................................................13

4.3. Control panel.......................................................................................................................14

5. STARTING AND OPERATING...................................................................................... 15

5.1. Security advice....................................................................................................................15

5.1.1. How to work while using a generator ...............................................................................15

5.1.2. How to work with an extension cable...............................................................................16

5.2. Accessories for data read in / out.....................................................................................16

5.2.1. Authorization card.............................................................................................................16

5.2.2. Bar code reading pen.......................................................................................................16

5.2.3. SD – card and reading device..........................................................................................16

5.2.4. USB card reader...............................................................................................................17

5.3. Pipes and sockets...............................................................................................................17

5.4. How to switch on the machine..........................................................................................18

5.5. How to weld with the ESI 4000..........................................................................................19

5.6. How to weld without fitting bar code................................................................................22

5.7. Error messages...................................................................................................................24