Kunststoffschweißtechnik

Contents

14.04.14 Working Instructions WIDOS MINIPLAST 2 Page 4 of 42

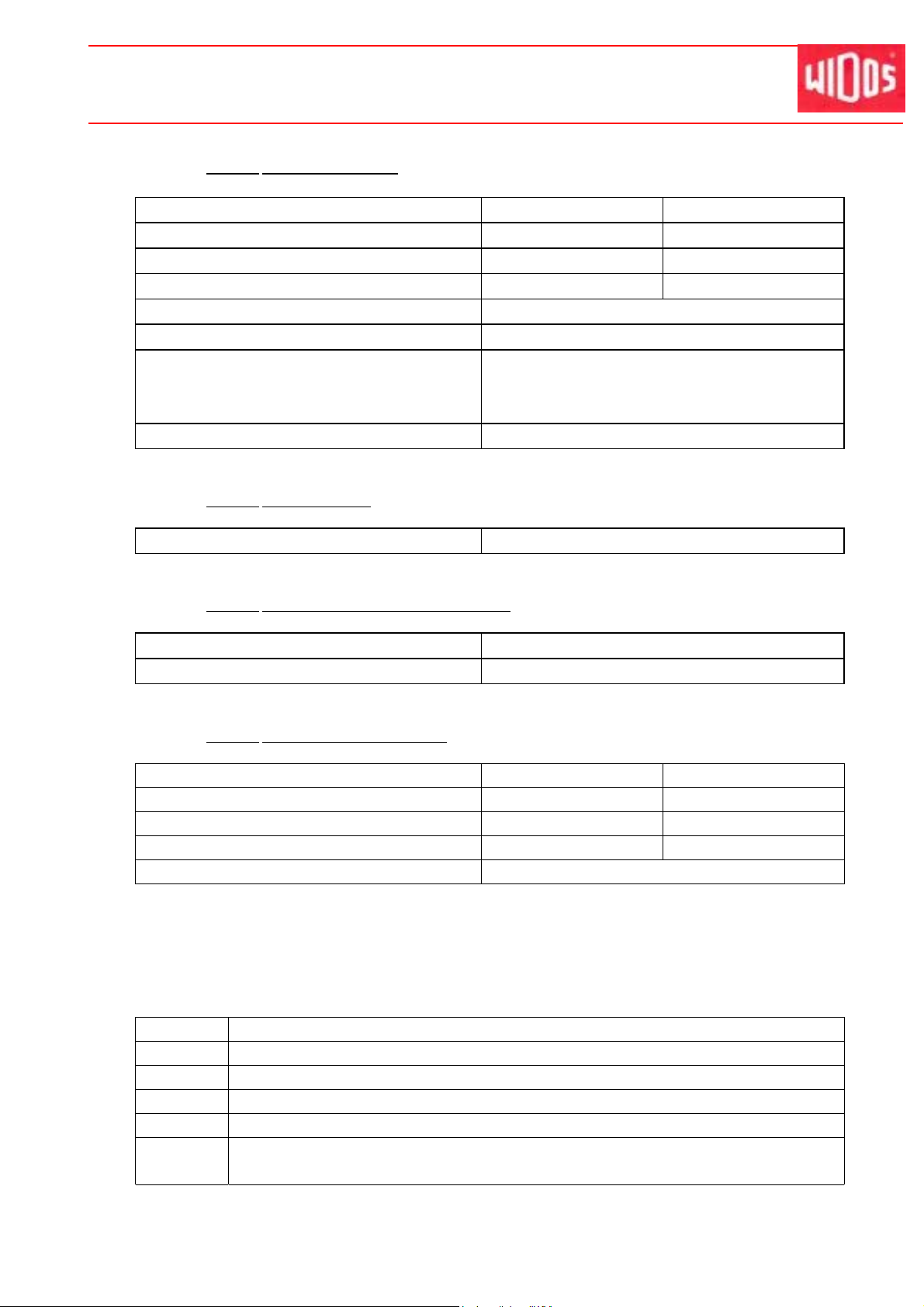

1. DESCRIPTION OF THE PRODUCT ....................................................................6

1.1. Usage and purpose-oriented use........................................................................................6

1.2. Overview................................................................................................................................6

1.3. Safety measures ...................................................................................................................7

1.4. Conformity.............................................................................................................................7

1.5. Designation of the product..................................................................................................7

1.5.1 Technical data ....................................................................................................................7

1.6. Equipment and accessories:...............................................................................................8

2. SAFETY RULES ..................................................................................................9

2.1. Explanation of the Symbols and Indications.....................................................................9

2.2. Obligations of the Owner.....................................................................................................9

2.3. Obligations of the worker ..................................................................................................10

2.4. Measures of organisation ..................................................................................................10

2.5. Instructions for the staff ....................................................................................................10

2.6. Structural modifications on the machine.........................................................................10

2.7. Cleaning the machine.........................................................................................................10

2.8. Danger while handling the machine .................................................................................11

2.9. Dangers caused by electric energy ..................................................................................11

2.10. Specific dangers.................................................................................................................11

2.10.1 Danger of being burnt by heating element, reception box and welding area..................11

2.10.2 Danger of stumbling over electric wires ...........................................................................11

2.10.3 Danger of cutting / squeezing / catching clothes..............................................................12

2.10.4 Risk of injury by noises.....................................................................................................12

2.11. Warranty and liability..........................................................................................................12

3. FUNCTIONAL DESCRIPTION...........................................................................13

4. OPERATING AND INDICATING ELEMENTS ...................................................14

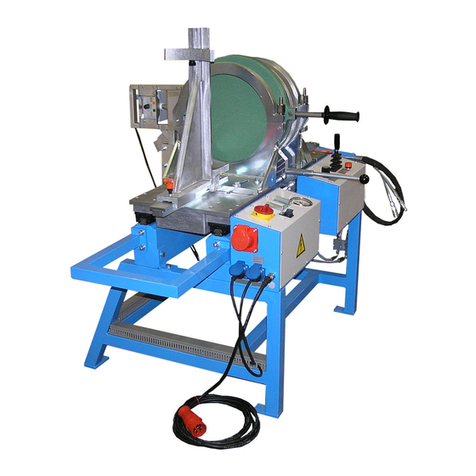

4.1. Elements on the basic machine / table support ..............................................................14

4.2. Elements at Heating Element and Planer.........................................................................15

4.3. Elements at the Electric Planer (optional)........................................................................16

5. STARTING AND OPERATING ..........................................................................17

5.1. Starting.................................................................................................................................17

5.1.1 Exchanging the Reduction Inserts....................................................................................18

5.2. Welding Process.................................................................................................................18

6. WELDING TABLES ...........................................................................................21

7. MAINTENANCE AND REPAIR..........................................................................25

7.1. General.................................................................................................................................25