Wieland ricos FLEX User manual

ricos

FLEX

ricos

FLEX digital input modules / digital output modules

83.036.2100.0 | 83.036.2200.0 | 83.036.2300.0

83.036.3100.0 | 83.036.3110.0 | 83.036.3150.0

83.036.3200.0 | 83.036.3210.0 | 83.036.3300.0

USER MANUAL

Dok.-Nr. BA000941

Stand: 01/2014 (Rev. A)

About this manual

2

Wieland Electric GmbH | BA000941 | 01/2014 (Rev. A)

This work is copyrighted material. The resulting rights remain with Wieland Electric Inc.

Any duplication of this document or parts thereof is permitted only within the limits of the

statutory provisions of the Copyright Act. Alteration or abridgement of this document

without the express written consent of Wieland Electric GmbH is prohibited.

ricos

FLEXis a trademark of Wieland Electric. Other names may in this assembly manual

mentioned product and brand- trademarks or registered trademarks of their respective

owners could be used, whose use by third parties for their own purposes could violate the

rights of the owners.

Every effort has been made to ensure that the information contained in this document was

complete and accurate at the time of publishing. Nevertheless, the authors retain the right

to modify the information. This customer document describes all the hardware units and

functions known at the present time. Descriptions may be included for units which are not

present at the customer site. The exact scope of delivery is described in the respective

purchase contract.

For more information regarding CE marking and Declaration of Conformity (DoC), please

contact your local Wieland Electric customer service organization.

SPEED7 is a registered trademark of profichip GmbH.

SIMATIC, STEP, SINEC, S7-300 and S7-400 are registered trademarks of Siemens AG.

BLUETOOTH® is a registered trademark of Special Interest Group (SIG).

Microsoft and Windows are registered trademarks of Microsoft Inc., USA.

Portable Document Format (PDF) and Postscript are registered trademarks of Adobe

Systems, Inc.

All other trademarks, logos and service or product marks specified herein are owned by

their respective companies.

NOTE

Conformity

Information

Trademarks

Inhalt

Wieland Electric GmbH | BA000941 | 01/2014 (Rev. A)

3

Inhalt

1About this manual ............................................................................................ 4

1.1 Objective and contents ................................................................................................ 4

1.2 Target audiences .......................................................................................................... 4

1.3 Structure of the manual ............................................................................................... 4

1.4 Icons Headings ............................................................................................................. 4

2Safety information ............................................................................................ 6

2.1 Applications conforming with specifications ............................................................... 6

2.2 Safety Information for Users ........................................................................................ 7

3Basics and Assembly ........................................................................................ 8

3.1 System conception ...................................................................................................... 8

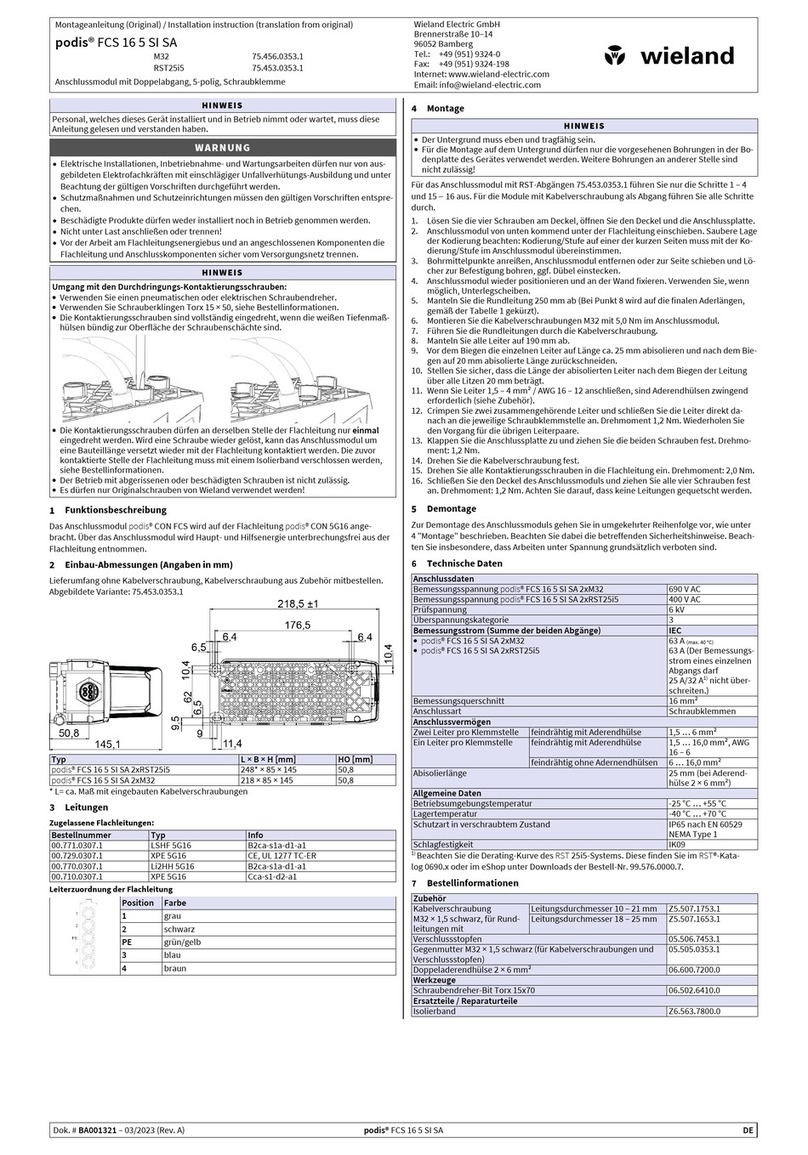

3.2 Dimensions ................................................................................................................ 11

3.3 Installation .................................................................................................................. 11

3.4 Demounting and module exchange ........................................................................... 14

3.5 Wiring ......................................................................................................................... 17

3.6 Trouble-shooting - LED .............................................................................................. 20

3.7 Installation guidelines ................................................................................................ 21

3.8 General data ............................................................................................................... 23

4Digital Input .................................................................................................... 25

4.1

ricos

FLEX 2xDI DC 24 V ........................................................................................... 25

4.2

ricos

FLEX 4xDI DC 24 V ........................................................................................... 27

4.3

ricos

FLEX 8xDI DC 24 V ........................................................................................... 30

5Digital Output ................................................................................................. 34

5.1

ricos

FLEX 2xDO DC 24 V 0,5 A ................................................................................ 34

5.2

ricos

FLEX 2xDO DC 24 V 2 A ................................................................................... 37

5.3

ricos

FLEX 4xDO DC 24 V 0,5 A ................................................................................ 39

5.4

ricos

FLEX 4xDO DC 24 V 2 A ................................................................................... 42

5.5

ricos

FLEX 8xDO DC 24 V 0,5 A ................................................................................ 45

5.6

ricos

FLEX 2xDO DC 30 V 3 A RELAY ....................................................................... 48

6Recommended literature ................................................................................ 51

7FAQ ................................................................................................................ 52

8Support ........................................................................................................... 53

About this manual

4

Wieland Electric GmbH | BA000941 | 01/2014 (Rev. A)

1About this manual

This manual describes the digital signal modules (SM) of the system

ricos

FLEX from

Wieland. Here you may find besides of a product overview a detailed description of the

single modules. You’ll receive information about the connection and the deployment of the

system

ricos

FLEX SM modules.

Please read this section carefully before you use this manual and the digital input module

from the system

ricos

FLEX from Wieland. Here you will find all the information required

for commissioning and operation.

1.1 Objective and contents

This manual describes the system

ricos

FLEX digital signal modules from Wieland. It

contains a description of the structure, project engineering and deployment.

This manual is valid for the following ordering numbers:

Product

Order number

Version:

HW

FW

ricos

FLEX digital input module

2xDI DC 24 V

83.036.2100.0 01 1.1.2

ricos

FLEX digital input module

4xDI DC 24 V

83.036.2200.0 01 1.1.2

ricos

FLEX digital input module

8xDI DC 24 V

83.036.2300.0 01 1.1.2

ricos

FLEX digital output module

2xDO DC 24 V 0,5 A

83.036.3100.0 01 1.1.2

ricos

FLEX digital output module

2xDO DC 24 V 2 A

83.036.3110.0 01 1.1.2

ricos

FLEX digital output module

2xDO DC 30 V 3 A RELAY

83.036.3150.0 01 1.1.2

ricos

FLEX digital output module

4xDO DC 24 V 0,5 A

83.036.3200.0 01 1.1.2

ricos

FLEX digital output module

4xDO DC 24 V 2 A

83.036.3210.0 01 1.1.2

ricos

FLEX digital output module

8xDO DC 24 V 0,5 A

83.036.3300.0 01 1.1.2

1.2 Target audiences

The manual is targeted at users who have a background in automation technology.

1.3 Structure of the manual

As a guidance the overall table of contents is available in the manual at the beginning.

The manual is available in electronic form as PDF-file (Adobe Acrobat Reader).

1.4 Icons Headings

Important passages in the text are highlighted by following icons and headings:

Guide to the

document

Availability

About this manual

Wieland Electric GmbH | BA000941 | 01/2014 (Rev. A)

5

Danger!

Immediate or likely danger.

Personal injury is possible.

Warning!

Possible danger. Not heeding this warning can lead to minor injuries.

Attention!

Damages to property is likely if these warnings are not heeded.

Caution!

Damages to property by electrostatic charges is likely if these warnings are not heeded.

NOTE!

Supplementary information and useful tips.

DANGER

WARNING

ATTENTION

NOTE

Safety information

6

Wieland Electric GmbH | BA000941 | 01/2014 (Rev. A)

2Safety information

This chapter is for your safety and the safety of equipment operators. Please read this

chapter carefully before working with a VPN-Router.

General Safety

•Personnel inalling, programming, operating or maintaining the wienet router must have

read and understood this manual.

•The personnel must be thoroughly familiar with all warnings, instructions and

requirements contained in this manual.

•The applicable local safety, protection and installation requirements must be observed.

•The user is solely responsible for selecting the correct product and the technical design

in accordance with appropriate local regulations

2.1 Applications conforming with specifications

The System

ricos

FLEX is constructed and produced for:

•communication and process control

•general control and automation applications

•industrial applications

•operation within the environmental conditions specified in the technical data

•installation into a cubicle

This device is not certified for applications in

• in explosive environments (EX-zone)

The manual must be available to all personnel in the

•project design department

•installation department

•commissioning

•operation

The following conditions must be met before using or commissioning the

components described in this manual:

•Modification to the process control system should only be carried out when the system

has been disconnected from power!

•Installation and modifications only by properly trained personnel

•The national rules and regulations of the respective country must be satisfied

(installation, safety, EMC ...)

National rules and regulations apply to the disposal of the unit!

Please note the following instructions:

•The ricos FLEX system may only be used in accordance with applicable national and

international regulations as well as any special restrictions on the use of the ricos FLEX

system in prescribed applications and environments.

•To avoid personal injury or damage to the equipment and ensure that all the relevant

regulations have been complied with, use only original accessories. Unauthorized

modifications or use of non -approved accessories may damage the system and violate

the law. Unauthorized modifications or use of unauthorized accessories may result in a

loss of warranty.

•The voltage at ricos FLEX system must not be exceeded.

WARNING

Applications

conforming

with

specifications

GEFAHR

Documentation

ATTENTION

Disposal

ATTENTION

Safety information

Wieland Electric GmbH | BA000941 | 01/2014 (Rev. A)

7

•Do not expose the ricos FLEX system to extreme environmental conditions. Protect the

system from dust, moisture and high temperatures.

•If the ricos FLEX system is used in the vicinity of medical devices, such as pacemakers

or hearing aids, special caution is required.

Any other use or modification to the system - even in the assembly and installation -

resulting in a loss of warranty claims against the Wieland Electric GmbH.

2.2 Safety Information for Users

ricos

FLEX modules make use of highly integrated components in MOS-Technology. These

components are extremely sensitive to over-voltages that can occur during electrostatic

discharges.

The following symbol is attached to modules that can be destroyed by electrostatic

discharges.

The symbol is located on the module, the module rack or on packing material and it

indicates the presence of electrostatic sensitive equipment.

It is possible that electrostatic sensitive equipment is destroyed by energies and voltages

that are far less than the human threshold of perception. These voltages can occur where

persons do not discharge themselves before handling electrostatic sensitive modules and

they can damage components thereby, causing the module to become inoperable or

unusable.

Modules that have been damaged by electrostatic discharges can fail after a temperature

change, mechanical shock or changes in the electrical load.

Only the consequent implementation of protection devices and meticulous attention to the

applicable rules and regulations for handling the respective equipment can prevent failures

of electrostatic sensitive modules.

Modules must be shipped in the origingal packing material.

When you are conducting measurements on electrostatic sensitive modules you should

take the following precautions:

•Floating instruments must be discharged before use.

•Instruments must be grounded.

Modifying electrostatic sensitive modules you should only use soldering irons with

grounded tips.

Personnel and instruments should be grounded when working on electrostatic sensitive

modules.

Handling of

electrostatic

sensitive

modules

Shipping of

modules

Measurements

and alterations

on electrostatic

sensitive

modules

Basics and Assembly

8

Wieland Electric GmbH | BA000941 | 01/2014 (Rev. A)

3Basics and Assembly

The focus of this chapter is on the introduction of the Wieland system

ricos

FLEX. Here

you will find the information required to assemble and wire a controller system consisting

of System

ricos

FLEX components.

Besides the dimensions the general technical data of system

ricos

FLEX will be found.

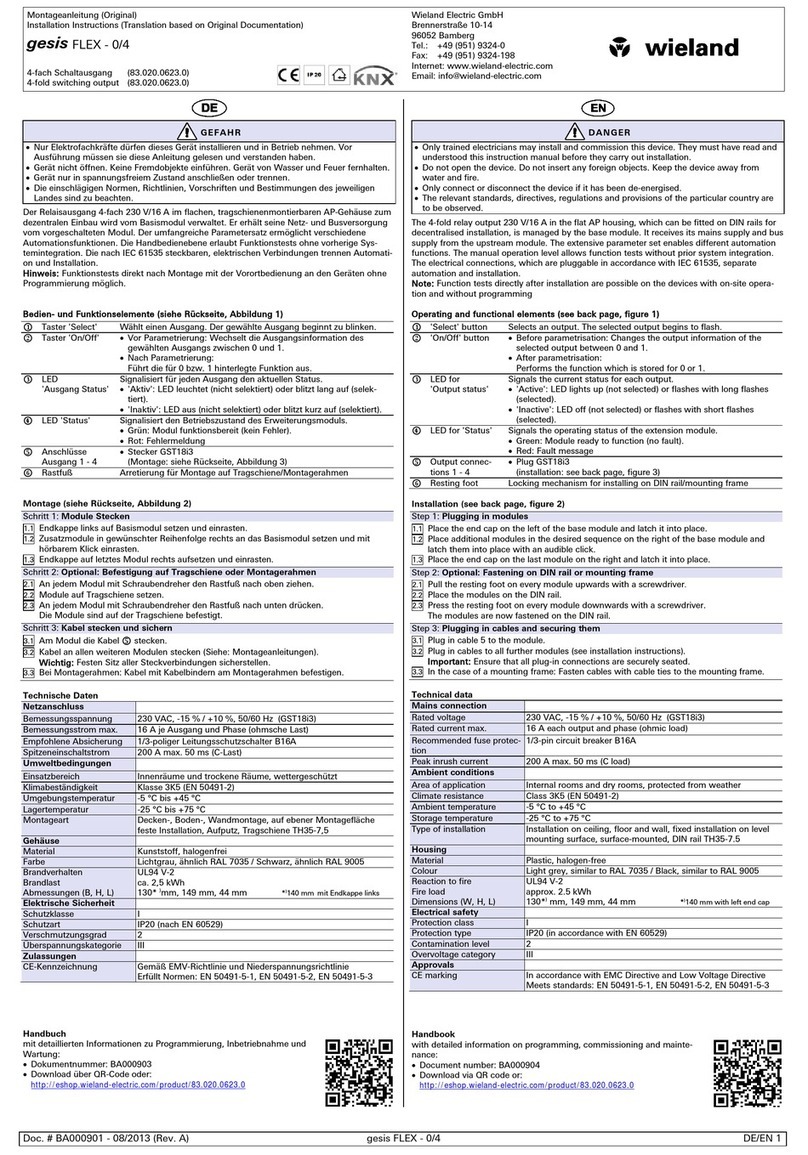

3.1 System conception

System

ricos

FLEX is a modular automation system for assembly on a 35 mm mounting

rail. By means of the peripheral modules with 2, 4 or 8 channels this system may properly

be adapted matching to your automation tasks.

The wiring complexity is low, because the supply of the DC 24 V power section is

integrated to the backplane bus and defective modules may be replaced with standing

wiring.

By deployment of the power modules in contrasting colors within the system, further

isolated areas may be defined for the DC 24 V power section supply, respectively the

electronic power supply may be extended with 2 A.

The system

ricos

FLEX consists of the following components:

•Bus coupler

•Periphery modules

•Power modules

•Accessories

Bus coupler

With a bus coupler bus interface and

power module is integrated to one casing.

With the bus interface you get access to a

subordinated bus system.

Via the integrated power module for power

supply the bus interface is supplied as well

as the electronic of the connected

extension modules.

The DC 24 V power section supply for the

linked extension modules is established via

a further connection at the power module.

By installing of up to 64 extension modules

at the bus coupler, these are electrically

connected, this means these are assigned

Overview

Components

Basics and Assembly

Wieland Electric GmbH | BA000941 | 01/2014 (Rev. A)

9

to the backplane bus, the electronic

modules are power supplied and each

extension module is connected to the DC

24 V power section supply.

Extension modules

[1]

[2]

Each extension module consists of a

terminal [1] and an electronic module [2].

Terminal module

The terminal module serves to carry the

electronic module, contains the backplane

bus with power supply for the electronic,

the DC 24 V power section supply and the

staircase-shaped terminal for wiring.

Additionally the terminal module has a

locking system for fixing at a mounting rail.

By means of this locking system your

ricos

FLEX system may be assembled outside of

your switchgear cabinet to be later

mounted there as whole system.

Electronic module

The functionality of a

ricos

FLEX extension

module is defined by the electronic

module, which is mounted to the terminal

module by a safe sliding mechanism.

With an error the defective module may be

exchanged for a functional module with

standing installation.

At the front side there are LEDs for status

indication.

For simple wiring each module shows a

corresponding connection diagram at the

front and at the side.

Basics and Assembly

10

Wieland Electric GmbH | BA000941 | 01/2014 (Rev. A)

Power module

In the system

ricos

FLEX the power supply

is established by power modules. These

are either integrated to the bus coupler or

may be installed between the periphery

modules. Depending on the power module

isolated areas of the DC 24 V power

section supply may be defined respectively

the electronic power supply may be

extended with 2 A.

For better recognition the color of the

power modules are contrasting to the

periphery modules.

Accessories

Shield bus carrier

The shield bus carrier serves to carry the

shield bus (10 mm x 3 mm) to connect

cable shields.

Shield bus carriers, shield bus and shield

fixings are not in the scope of delivery.

They are only available as accessories.

The shield bus carrier is mounted

underneath the terminal of the terminal

module.

With a flat mounting rail for adaption to a

flat mounting rail you may remove the

spacer of the shield bus carrier.

Bus cover

With each bus coupler, to protect the

backplane bus connectors, there is a

mounted bus cover in the scope of

delivery. You have to remove the bus cover

of the bus coupler before mounting a

ricos

FLEX module.

For the protection of the backplane bus

connector you always have to mount the

bus cover at the last module of your

system again.

Basics and Assembly

Wieland Electric GmbH | BA000941 | 01/2014 (Rev. A)

11

3.2 Dimensions

Dimensions bus coupler (in mm)

104

109

76.5 48.5

49

Dimensions periphery module (in mm)

104

109

76.5 15

133

12.9

Dimensions electronic module (in mm)

55.5

62 12.9

3.3 Installation

There is a locking lever at the top side of the terminal module. For mounting and

demounting this locking lever is to be turned upwards until this engages audible.

Now the module may be pulled forward.

For mounting plug the module to the module installed before and push the module to the

mounting rail guided by the strips at the upper and lower side of the module.

The module is fixed to the mounting rail by pushing downward the locking lever.

Functional

principle

Basics and Assembly

12

Wieland Electric GmbH | BA000941 | 01/2014 (Rev. A)

The modules may either separately be mounted to the mounting rail or as block. Here is to

be considered that each locking lever is opened.

Clack

12 3

For the exchange of an electronic module, the electronic module may be pulled forward

after pressing the unlocking lever at the lower side of the module.

For installation plug the electronic module guided by the strips at the lower side until this

engages audible to the terminal module.

1. Press

2. Pull

Clack

1 2 3

The modules were directly be mounted to the mounting rail and so connected to the

backplane bus and the power supply for the electronic and power section.

Up to 64 modules may be mounted. Please consider here that the sum current of the

electronic power supply does not exceed the maximum value of 3 A. By means of the

power module PW 24 V/5 V TM (order number: 83.036.0040.0) the current of the

electronic power supply may be expanded with 2 A. More about this may be found at

"Wiring".

•Mount the mounting rail! Please consider that a clearance from the middle of the

mounting rail of at least 80 mm above and 60 mm below, respectively 80 mm by

deployment of shield bus carriers, exist.

Mounting

proceeding

Mounting

mounting rail

Basics and Assembly

Wieland Electric GmbH | BA000941 | 01/2014 (Rev. A)

13

80mm

80mm

60mm 65mm

•Start at the left side with the head module (e. g. bus coupler). For this turn both

locking lever upwards, put the head module to the mounting rail and turn both

locking lever downward.

•Before mounting the periphery modules you have to remove the bus cover at the

right side of the Head module by pulling it forward. Keep the cover for later

mounting.

1 2

•Mount the periphery modules you want.

12

Clack

3

•After mounting the whole system, to protect the backplane bus connectors at the

last module you have to mount the bus cover, now.

Mounting head module

(e. g. bus coupler)

Mounting

periphery modules

Mounting the

bus cover

Basics and Assembly

14

Wieland Electric GmbH | BA000941 | 01/2014 (Rev. A)

•The shield bus carrier (available as accessory) serves to carry the shield bus to

connect cable shields. The shield bus carrier is mounted underneath the terminal of

the terminal module. With a flat mounting rail for adaption to a flat mounting rail

you may remove the spacer of the shield bus carrier.

Clack

3.4 Demounting and module exchange

With demounting and exchange of a module, head module (e. g. bus coupler) or a group

of modules for mounting reasons you have always to remove the electronic module of the

just mounted right module. After the mounting it may be plugged again.

For the exchange of an electronic module, the electronic module may be pulled forward

after pressing the unlocking lever at the lower side of the module.

For installation plug the electronic module guided by the strips at the lower side until this

engages audible to the terminal module.

1. Press

2. Pull

Clack

1 2 3

•Remove if exists the wiring. More about this may be found at "Wiring".

•Press the unlocking lever at the lower side of the just mounted right module and

pull it forward.

•Turn the locking lever of the module to be exchanged upwards.

•Pull the module forward.

Mounting

shild bus carrier

Proceeding

Exchange of an

electronic module

Exchange of a module

Basics and Assembly

Wieland Electric GmbH | BA000941 | 01/2014 (Rev. A)

15

123

•For mounting turn the locking lever of the module to be mounted upwards.

•To mount the module put it to the gap between the both modules and push it,

guided by the stripes at both sides, to the mounting rail.

•Turn the locking lever downward again.

•Plug again the electronic module, which you have removed before.

456

Bus interface and power module of a head module may not be separeted! Here you may

only exchange the electronic module!

•Remove if exists the wiring of the head module. More about this may be found at

"Wiring".

•Press the unlocking lever at the lower side of the just mounted right module and

pull it forward.

•Turn all the locking lever of the head module to be exchanged upwards.

•Pull the head module forward.

12

•For mounting turn all the locking lever of the head module to be mounted upwards.

Exchange of a head

module (e. g. bus

coupler)

Basics and Assembly

16

Wieland Electric GmbH | BA000941 | 01/2014 (Rev. A)

•To mount the head module put it to the left module and push it, guided by the

stripes, to the mounting rail.

•Turn all the locking lever downward again.

•Plug again the electronic module, which you have removed before.

345

•Remove if exists the wiring of the module group. More about this may be found at

"Wiring".

•Press the unlocking lever at the lower side of the just mounted right module of the

module group and pull it forward.

•Turn all the locking lever of the module group to be exchanged upwards.

1

•Pull the module group forward.

2

•For mounting turn all the locking lever of the module group to be mounted

upwards.

•To mount the module group put it to the gap between the both modules and push

it, guided by the stripes at both sides, to the mounting rail.

Exchange of a module

group

Basics and Assembly

Wieland Electric GmbH | BA000941 | 01/2014 (Rev. A)

17

34

•Turn all the locking lever downward againg.

•Plug againg the electronic module, which you have removed before.

5

3.5 Wiring

Terminals with spring clamp technology are used for wiring. The spring clamp technology

allows quick and easy connection of your signal and supply lines.

In contrast to screw terminal connections this type of connection is vibration proof.

10mm

Umax: 240 V AC / 30 V DC

Imax: 10 A

Cross section: 0,08 mm2 … 1,5 mm2 (AWG 28 … 16)

Stripping length: 10 mm

•Insert a suited screwdriver at an angel into the square opening as shown (step 1).

Press and hold the screwdriver in the opposite direction to open the contact spring.

•Insert the stripped end of wire into the round opening (step 2). You can use wires

with a cross section of 0.08 mm² to 1.5 mm².

•By removing the screwdriver, the wire is securely fixed via the spring contact to the

terminal (step 3).

Connectors

Data

Wiring

procedure

Standard wiring

12 3

Basics and Assembly

18

Wieland Electric GmbH | BA000941 | 01/2014 (Rev. A)

DC24V

0V

DC24V

0V

1

2

DC 24V max. 10A

S y s DC 5V max. 3A

1 DC 24 V for power section supply I/O are (max. 10 A)

2 DC 24 V for electronic power supply bus coupler and I/O area

Since the power section supply is not internally protected, it is to be externally protected

with a fuse, which corresponds to the maximum current. This means max. 10 A is to be

protected by a 10 A fuse (fast) respectively by a line circuit breaker 10 A characteristics Z!

The electronic power section supply is internally protected against higher voltage by fuse.

The fuse is within the power module.

If the fuse releases, its electronic module must be exchanged!

•The power section supply is to be externally protected with a fuse, which

corresponds to the maximum current. This means max. 10 A is to be protected with

a 10 A fuse (fast) respectively by a line circuit breaker 10 A characteristics Z!

•It is recommended to externally protect the electronic power supply for bus coupler

and I/O area with a 2 A fuse (fast) respectively by a line circuit breaker 2 A

characteristics Z.

•The electronic power supply for the I/O area of the power module PW 24 V / 5 V

(order number: 83.036.0040.0) should also be externally protected with a 1 A fuse

(fast) respectively by a line circuit breaker 1A characteristics Z.

After PowerON of the System

ricos

FLEX the LEDs RUN respectively MF get on so far as

the sum current does not exceed 3 A.

With a sum current greater than 3 A the LEDs may not be activated. Here the power

module with the order number 83.036.0040.0 is to be placed between the peripheral

modules. More concerning this may be found at page

Fehler! Textmarke nicht definiert.

.

If the 10 A for the power section supply is no longer sufficient, you may use the power

module from

ricos

FLEX with the order number 83.036.0030.0. So you have also the

possibility to define isolated groups.

The power module with the order number 83.036.0040.0 is to be used if the 3 A for the

electronic power supply at the backplane bus is no longer sufficient. Additionally you get

an isolated group for the DC 24 V power section supply with 4 A.

By placing the power module 83.036.0040.0 at the following backplane bus modules may

be placed with a sum current of max. 2 A. Afterwards the power module is to be placed

again.

To secure the power supply, the power modules may be mixed used.

ATTENTION

NOTE

Fusing

State of the

electronic

power supply

via LED

Deployment of

the power

modules

Basics and Assembly

Wieland Electric GmbH | BA000941 | 01/2014 (Rev. A)

19

Sys DC 5V: ---

DC 24V: 10A

Sys DC 5V: ---

DC 24V: 10A

DC24V

0V

DC24V

0V

DC 24V max. 10A

S ys DC 5V max . 3A

DC 24V max. 10A DC 24V max. 10A

DC24V

0V DC24V

0V

1

2

1 1

Sys DC 5V: 2A

DC 24V: 4A

Sys DC 5V: 2A

DC 24V: 4A

DC24V

0V

DC24V

0V

DC 24V max. 10A

S ys DC 5V max . 3A S ys DC 5V max. 2A S ys DC 5V max . 2A

DC 24V max. 4A DC 24V max. 4A

DC24V

0V DC24V

0V

1

2

3 3

DC24V

0V

4

DC24V

0V

4

1 DC 24 V for power section supply I/O area (max. 10 A)

2 DC 24 V for electronic power supply bus coupler and I/O area

3 DC 24 V for power section supply I/O area (max. 4 A)

4 DC 24 V for electronic power supply I/O area

To attach the shield the mounting of shield bus carriers are necessary.

The shield bus carrier (available as accessory) serves to carry the shield bus to connect

cable shields.

The shield bus carrier is mounted underneath the terminal of the terminal module. With a

flat mounting rail for adaption to a flat mounting rail you may remove the spacer of the

shield bus carrier.

After mounting the shield bus carrier with the shield bus, the cables with the accordingly

stripped cable screen may be attached and fixed by the shield clamp.

Power module

PW DC 24 V

Power module

PW 24 V/5 V TM

Shield

attachment

Basics and Assembly

20

Wieland Electric GmbH | BA000941 | 01/2014 (Rev. A)

Clack

1

2

3

4

1 Shield bus carrier

2 Shield bus (10 mm x 3 mm)

3 Shield clamp

4 Cable shield

3.6 Trouble-shooting - LED

Each module has the LEDs RUN and MF on its front side. Errors or incorrect modules may

be located by means of these LEDs.

In the following illustrations flashing LEDs are marked by ☼.

Behavior:

After PowerON the RUN LED of each module is off and the MF LED of

each module is sporadically on.

Reason:

The maximum current for the electronic power supply is exceeded.

Remedy:

As soon as the sum current of the electronic power supply is exceeded,

always place the power module PW 24 V / 5 V (order number:

83.036.0040.0).

More concerning this may be found above at "Wiring".

Behavior:

After PowerON the MF-LED of one module respectively more modules

flashes. The RUN-LED remains off.

Reason:

At this position a module is placed, which does not correspond to the

configured module.

General

Sum current of

the electronic

power supply

exceeded

Error in

configuration

RUN

MF

RUN

MF RUN

MF RUN

MF RUN

MF RUN

MF RUN

MF

RUN

MF RUN

MF RUN

MF

RUN

MF

RUN

MF RUN

MF RUN

MF RUN

MF

RUN

MF

RUN

MF RUN

MF RUN

MF

RUN

MF

Table of contents

Other Wieland Control Unit manuals

Wieland

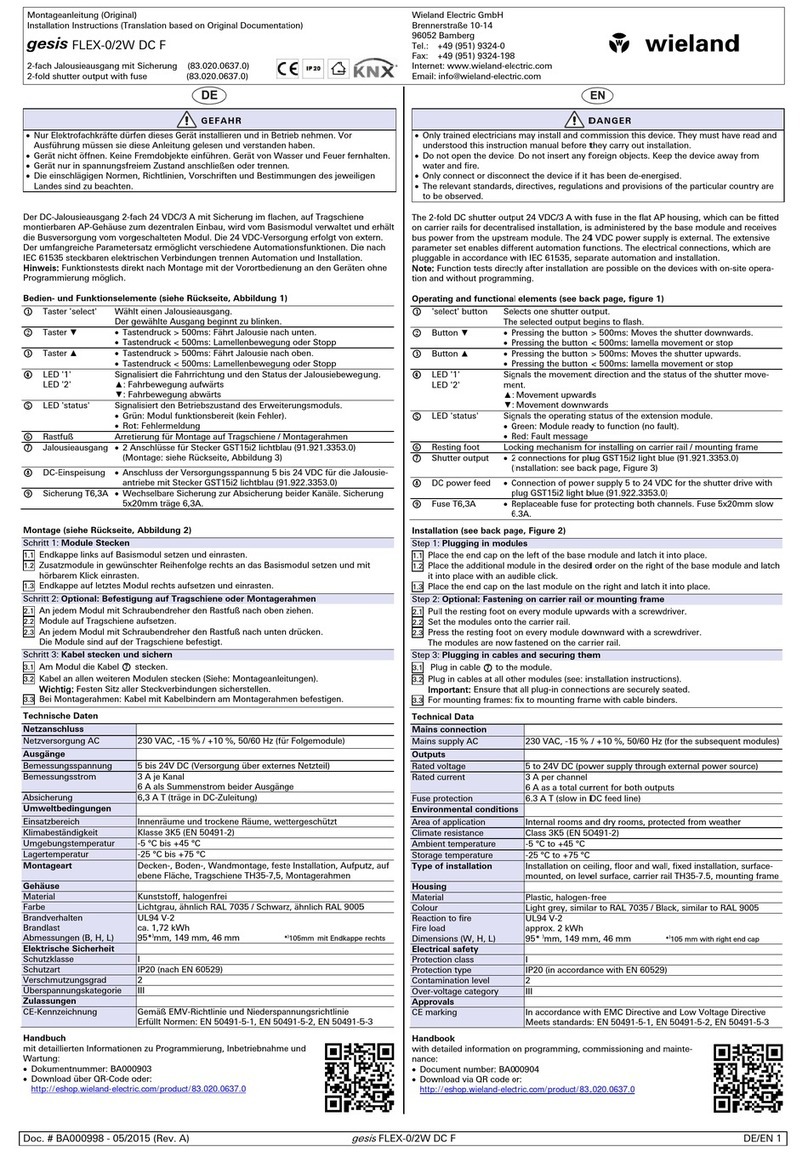

Wieland GESIS FLEX-0/2W DC User manual

Wieland

Wieland podis FCS 6 5 SI SA User manual

Wieland

Wieland gesis FLEX-0/2W DC F User manual

Wieland

Wieland gesis RM Series User manual

Wieland

Wieland GESIS FLEX-0/4 User manual

Wieland

Wieland gesis FLEX-MS User manual

Wieland

Wieland gesis FLEX-8/0 (12) User manual

Wieland

Wieland gesis KNX FLEX-BAS User manual

Wieland

Wieland SP-COP1 User manual

Wieland

Wieland PROFIBUS-DP Series User manual