9WIKA operating instructions, model CPH62I0

11221801.02 02/2011 GB/D/F/E

GB

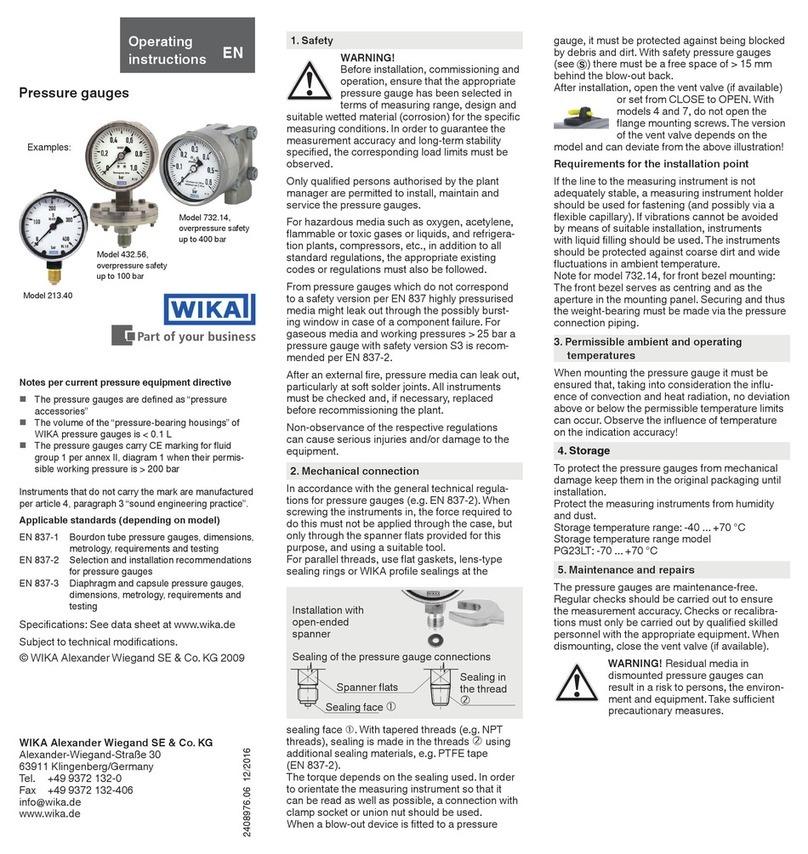

2. Safety

2.4 Special hazards

WARNING!

Observe the information given in the applicable type examination

certicate and the relevant country-specic regulations for installation

and use in hazardous areas (e.g.

VDE 0165,

IEC 60079-14, NEC, CEC).

Non-observance can result in serious injury and/or damage to equip-

ment.

For additional important safety instructions for insturments with ATEX

approval see chapter “2.3 Additional safety instructions for instruments

with ATEX approval”.

WARNING!

For hazardous media such as oxygen, acetylene, ammable or toxic

gases or liquids, and refrigeration plants, compressors, etc., in addition

to all standard regulations, the appropriate existing codes or regula-

tions must also be followed.

DANGER!

Danger of death caused by electric current

Upon contact with live parts, there is a direct danger of death.

Operation using a defective power supply unit (e.g. short circuit from

the mains voltage to the output voltage) can result in life-threatening

voltages on the hand-held pressure indicator!

WARNING!

Residual media in dismounted hand-held pressure indicator or

pressure sensor can result in a risk to persons, the environment and

the equipment.

Take sucient precautionary measures.

Should a failure occur, aggressive media with extremely high tempera-

ture and under high pressure or vacuum may be present at the

handheld pressure indicator’s sensors.

If there is a possibility that the instrument can no longer be used safely, the instrument

must be switched o immediately and marked accordingly to prevent re-use.

The safety of the operator may be endangered if, for example:

■

there is visible damage to the instrument.

■

the instrument is not working as specied.

■

the instrument has been stored under unsuitable conditions for an extended period of

time.

If there is any doubt, please return the instrument to the manufacturer for repair or

maintenance.