4Mensor operating instructions Vacuum Pump and Compressor Set, Model 83

EN

1. General Information

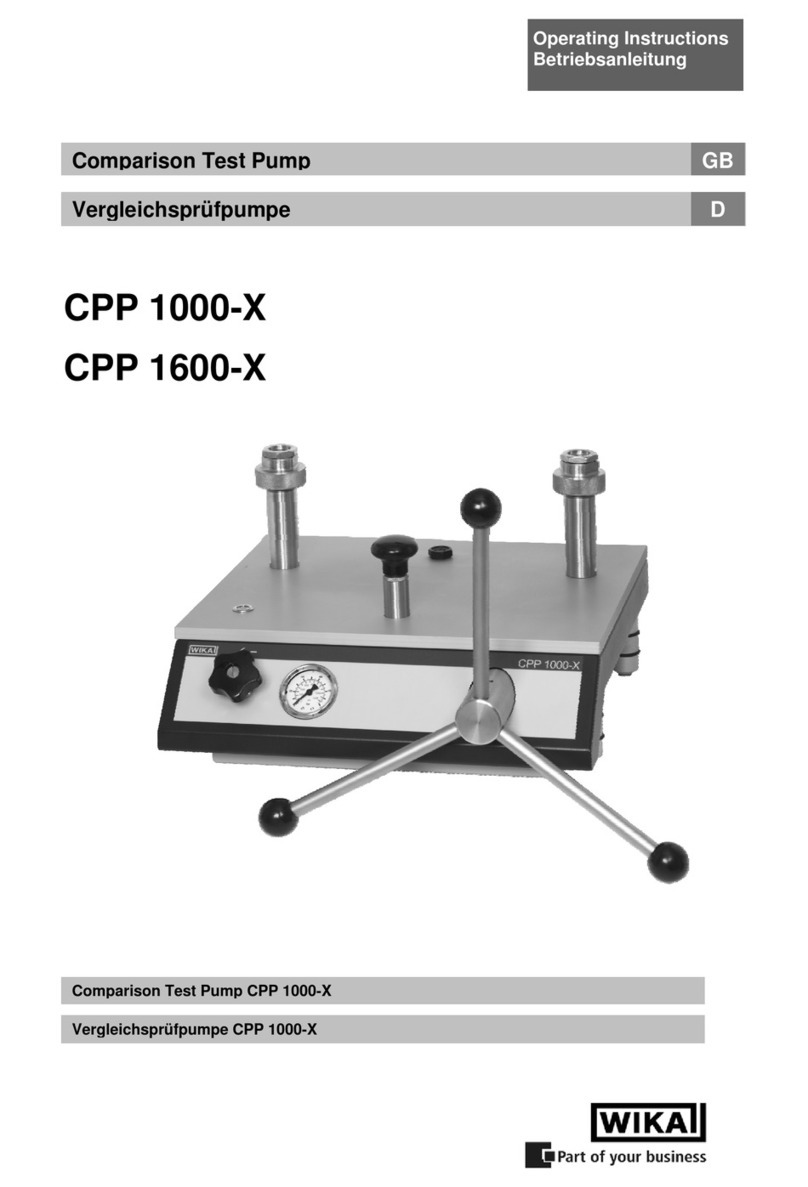

The Mensor Model 83 is a pump and/or compressor set that complements a pressure controller and fits on or under a bench,

in a rack, or on a table. The compressor is an oil-less pump with a maximum pressure of 40 psi with an open flow of 39 scfh.

The vacuum pump is also oil-less and can achieve 29 inHg of vacuum with an open flow of 20 scfh. In avionics terms, this set

is capable of 65,000 feet of altitude and airspeeds in excess of 1000 knots. Both units are shock mounted to reduce noise and

vibration. Each unit has a power switch/breaker and can be run independently. This same configuration can also be produced in a

standard 19 inch, 4U (7” high) rack mount chassis or desktop version.

1.1 Further information:

Mensor Corporation

- Address 201 Barnes Dr., San Marcos, TX 68666

- Internet address: www.mensor.com

- Relevant data sheet: CT 25.12

- Application consultant: Tel.: (+1) 512-396-4200

(+1) 800-984-4200 (USA only)

Fax: (+1) 512-396-1820

E-Mail: sales@mensor.com

Importer for Europe

WIKA Alexander Wiengand SE & Co. KG

-Address Alexander Wiegand-Straße

63911 Klingenberg, Germany

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: CT 25.12

- Application consultant: Tel.: (+49) 9372/132-5015

Fax: (+49) 9372/132-8767

1.2 Warranty

All products manufactured by Mensor are warranted to be free of defects in workmanship and materials for a period of two year

from the date of shipment. No other express warranty is given, and no affirmation of Seller, by words or actions, shall constitute

a warranty. SELLER DISCLAIMS ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR

PURPOSES WHATSOEVER. If any defect in workmanship or material should develop under conditions of normal use and service

within the warranty period, repairs will be made at no charge to the original purchaser, upon delivery of the product(s) to the

factory, shipping charges prepaid. If inspection by Mensor or its authorized representative reveals that the product was damaged

by accident, alteration, misuse, abuse, faulty installation or other causes beyond the control of Mensor, this warranty does not

apply. The judgment of Mensor will be final as to all matters concerning condition of the product, the cause and nature of a defect,

and the necessity or manner of repair. Service, repairs or disassembly of the product in any manner, performed without specific

factory permission, voids this warranty.

MENSOR MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS MANUAL, INCLUDING, BUT NOT LIMITED TO, THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Mensor shall not be liable for

errors contained herein or for incidental or consequential damages in connection with the furnishing, performance, or use of this

material.

1.2.1 FCC Emission Notice

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC

Rules.These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in

a residential environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

General information