Wilbur Curtis Company Gemini IntelliFresh GEMTIF User manual

1

Symbols

WARNINGS – To help avoid personal injury

Important Notes/Cautions – from the factory

Sanitation Requirements

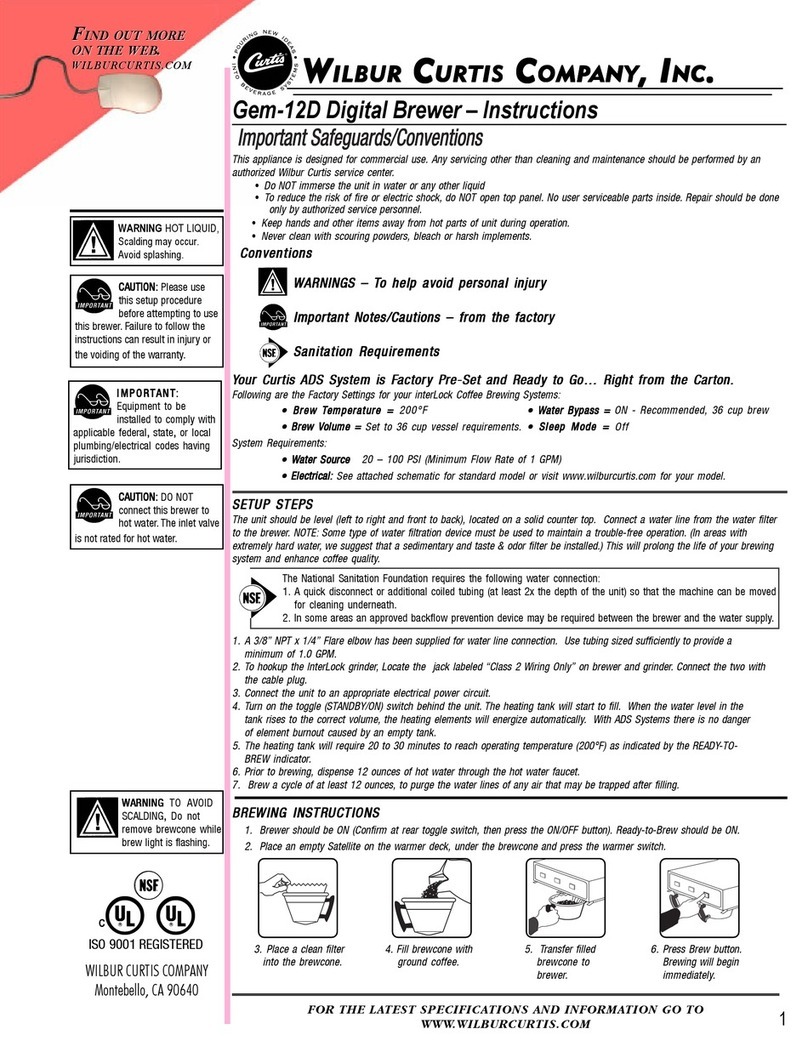

Important Safeguards/Conventions

This appliance is designed for commercial use. Any servicing other than cleaning and preventive maintenance

should be performed by an authorized Wilbur Curtis service technician.

•DONOTimmersetheunitinwateroranyotherliquid

•Toreducetheriskofreorelectricshock,DONOTopentheservicepanels.Therearenouserservice-

able parts inside.

•Keephandsandotheritemsawayfromhotsurfacesofunitduringoperation.

•Nevercleanwithscouringpowders,bleachorharshchemicals.

Your IntelliFresh brewer is Factory Pre-Set and Ready to Go… Right from the Box.

Following are the Factory Settings for IntelliFresh brewer:

• Brew Temperature = 200°F • Water Bypass = On LARGE & MEDIUM brew only

• Brew Volume = Large-Medium-Small • Energy Save Mode = Off

• Quality Timer = 120 Minutes • Warmer Auto-Off = 10 Hours

System Requirements:

• Water Source 20 – 90 PSI (Minimum Flow Rate of 1 GPM)

• Electrical: See attached schematic for standard model or visit www.wilburcurtis.com for your model.

SETUP STEPS

Theunitshouldbelevel(lefttorightandfronttoback)andlocatedonasecurecountertop.Connectawater

linefromthewaterlterwithaminimumowrateof1gallonperminutetothebrewer.

NOTE:Awaterltrationsystemmustbeusedtohelpmaintaintrouble-freeoperation.Air must be purged

from the cartridge prior to connection to equipment.Inareaswithextremelyhardwater,wehighlyrec-

ommendtheuseofaCurtisapprovedwaterlter.Forourfulllineoflters,logontowww.wilburcurtis.com.

1.A3/8”Flarex3/8”Malepipeelbowissuppliedwiththebrewerforwaterlineconnection.Usetubingsized

sufcientlytoprovideaminimumof1.0GPM.

2.Connecttheunittoanappropriateelectricalpowercircuit.

3.Turnonthetoggle(STANDBY/ON)switchbehindtheunit.Theheatingtankwillstarttoll.Whenthewater

levelinthetankrisestothecorrectvolume,theheatingelementswillenergizeautomatically.Withthe

IntelliFreshbrewer,thereisnodangerofelementburnoutcausedbyoverheatinganemptytank.

4.Theheatingtanktypicallyrequires20to30minutestoreachoperatingtemperature(200°F),indicated

whenREADYisdisplayedontheLCDscreen.

5.Priortobrewing,dispense12ouncesofhotwaterthroughthehotwaterfaucet.

6. Brewacycleofatleast12ounces,topurgethewaterlinesofanyairthatmaybetrappedafterlling.

Wilbur Curtis Company, inC.

Models

GEMTIF

GEMSIF

GEM3IF

Service Manual – Gemini IntelliFresh Brewer

CAUTION:DONOT

connectthisbrewertohot

water.Theinletvalveis

notratedforhotwater.

CAUTION:Pleaseuse

this setup procedure

before attempting to use

thisbrewer.Failuretofollowthe

instructions can result in injury or the

voidingofthewarranty.

IMPORTANT:Equipment

to be installed to comply

withapplicablefederal,

state,orlocalplumbing/electrical

codes having jurisdiction.

FOR THE LATEST SPECIFICATIONS AND INFORMATION GO TO WWW.WILBURCURTIS.COM

ISO9001:2008

Wilbur Curtis Company

Montebello,CA90640

Tel:(323)837-2300

www.wilburcurtis.com

NSFInternationalrequiresthefollowingwaterconnection:

1. Aquickdisconnectoradditionalcoiledtubing(atleast2xthedepthoftheunit)sothatthemachine

can be moved for cleaning underneath the unit.

2. Thisequipmentistobeinstalledwithadequatebackowprotectiontocomplywithapplicable

federal,stateandlocalcodes.

3. Waterpipeconnectionsandxturesdirectlyconnectedtoapotablewatersupplyshallbesized,

installedandmaintainedinaccordancewithfederal,state,andlocalcodes.

2

GEMINI IF BREWER

SATELLITE

UCM CONTROL

IF CONNECTOR

INTELLIFRESH FUNCTION & FEATURES

WARNING: AVOIDSCALDING,Donotremovebrewconewhilebrewlightisashing.

1.BrewershouldbeON.Conrmthisatreartoggleswitch,thenpresstheON/OFFbuttonontheUCM(UniversalControlModule).Ready-to-

Brewshouldbeonthedisplay.IfthebrewerisconnectedtoanInterLockgrinder,thegrindershouldbeon.WhenInterlockconnectionis

made,grindcoffeeatthistime.

2.PositionanemptySatelliteontothebrewdeck.

NOTE:OnlyuseIntellifreshSatellitesonIntellifreshBrewers.

6. Pressappropriate

brewbutton.

Brewingwillbegin

immediately.

5. Transferlledbrew

conetobrewer.

3. Placeacleanlter

intothebrewcone. 4. Fillbrewconewith

appropriate amount

of ground coffee.

INTELLIFRESH BREWING INSTRUCTIONS

TheIntelliFreshsystemwillalertyouwhenthecoffeehasexceededthedesiredhold-

ing time. The Intellifresh system is activated by a connector on the Satellite connecting

tothecorrespondingconnectoronthecenterpanel.IntelliFreshisadjustablethrough

theUCMcontrolleronthebrewer.

Quality Timer(FactorySetto2hours)

Press¤toselect,press<or>tochoosethedesiredsetting.Range20min.to240

min.Thetimerisintendedtonotifytheuserwhenthecoffeelosesitsfreshness.The

indicatorlight(LED)onthesatellitewillremainsolidreduntiltheQualityTimerexpires

(FactorySetto2hours).AtexpirationtheLEDwillashandremainashingatthe

factory setting for an additional 8 hours. The additional 8 hours is controlled by the

WarmerAuto-Offsetting(seebelowWarmerAutoOff).

• SettingRange:20–240minutes.Thedefaulttimeis2hours.

• TimeExpirationIndicator:LEDashesafterexpirationofQualityTimerSetting

foruptoatotalof12hours.Thedefaulttimeis8hoursafterexpirationofthe

QualityTimer.

Warmer Auto-Off (Factorysetto10Hrs.)

Press¤toselect<or>toadjustfrom1-12

hours. This feature has higher priority than the

QualityTimer.Itshutsoffthewarmersaftera

pre-determinedtime(factorysetat10hours)

startingwhentheBrewButtonispushed.The

QualityTimerdoesnotaffectthisfunction.

3

The G3/Gold Cup Series Brewing System is Factory Pre-Set for Optimum Performance.

After connection to water and power; the rear toggle switch must be on. You will hear a beep sound, indicating power is available to the controller.

The control displays . Press ON/OFF button and the screen will display . After three seconds, is displayed.

Water will ll the tank (approximately 2-3 minutes depending on water ow rate). When the proper level is reached will appear on the

screen. It takes approximately 20 minutes to reach setpoint temperature of 200°F.

Control will display when temperature reaches the setpoint (200°F). Unit is now ready to brew.

<GEMINI TWIN>

WILBUR CURTIS

CURTIS CURTIS

FILLING

CURTIS

HEATING

CURTIS

READY

PROGRAM

MENUS

Allprogrammingselectionsareperformedwiththethreecenter

buttons.

Thesymbolsbelowthebuttonsare:

ScrollLEFT

¤SELECTIONorENTERtosavenewparameter

ScrollRIGHT

IMPORTANTNOTE:

GEM INTELLIFRESH

4

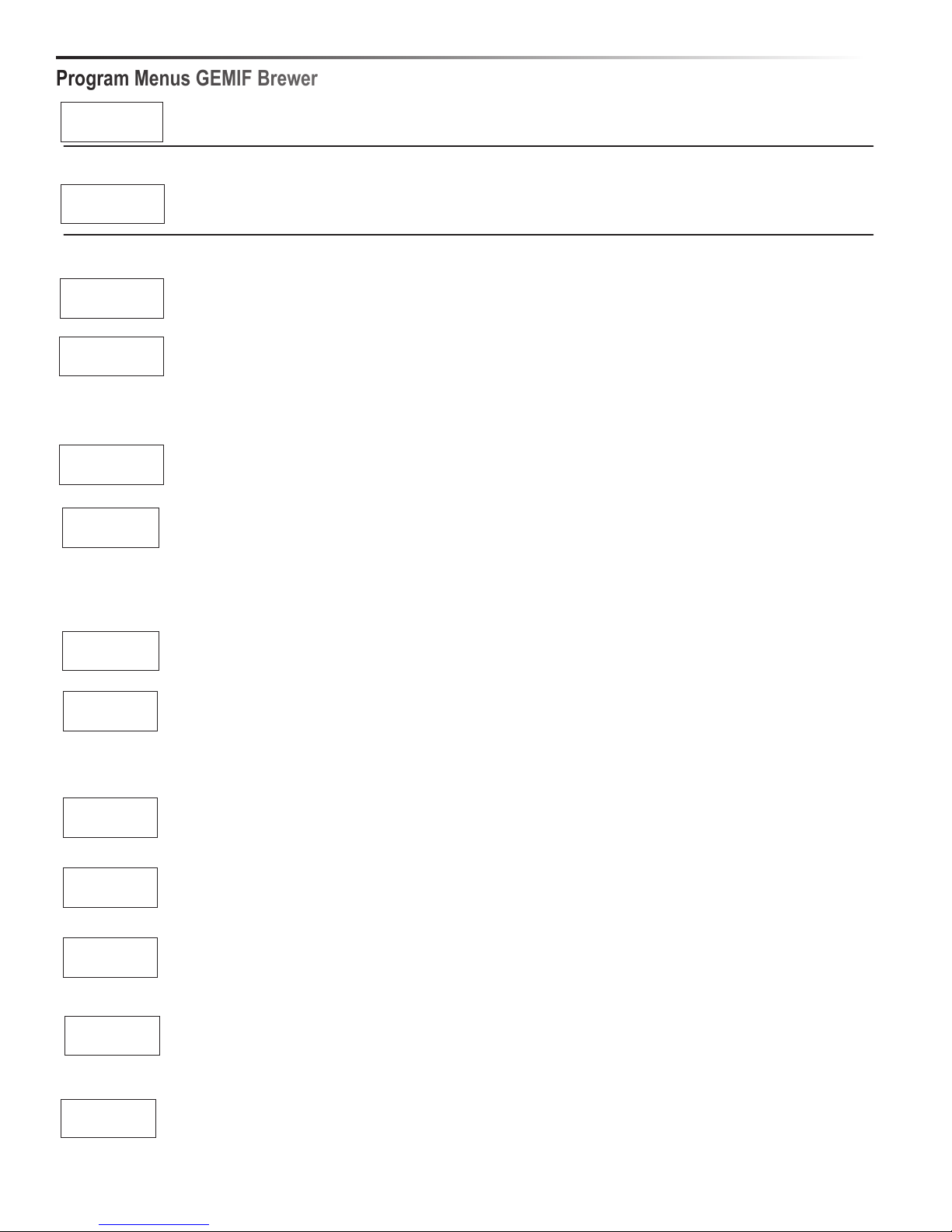

Program Menus GEMIF Brewer

ProgramMenus

Temperature

EnergySaveMode

BrewCountOdom

Global Recipes

BannerName

Access Code

Service Call

MasterReset

ColdBrewLock

BrewCountTotal

From Program Menus press > display will show the next feature Global Recipes.

QualityTimer

NON-BREW PROGRAMMING

Temperature (Factory set to 200ºF)

Press ¤ to Select. Press < or > to move to desired temperature and then ¤ to set. Temperature is programmable from

170ºF to 206ºF in 2-degree increments.

Energy Save Mode (Factory set to OFF)

Press ¤ to Select, < or > ON, OFF or ON 140ºF , ¤ to set. When in ON, unit will automatically shut off 4 hours from last

brew. When feature is OFF, unit does not utilize the energy saving mode.

In the ON 140ºF position, temperature lowers to 140ºF, if unit has not brewed in 4 hours. This feature will save energy by

maintaining a lower temperature in the tank in periods of non-operation.

Brew Count Odom

Press ¤ to display total brew cycles. Press EX or Reset.

Quality Timer (Factory set to 120 Minutes)

Press ¤ to select, press < or > to choose desired setting. Range 20 min. to 240 min. The timer is intended to notify the

user when the coffee loses its freshness. The indicator light (LED) on the satellite will remain solid until the Quality Timer

expires (Factory Set to 120 minutes). At expiration the LED will ash and remain ashing at the factory setting for an ad-

ditional 8 hours. The additional 8 hours is controlled by the Warmer Auto-Off setting.

NOTE: LED solid means fresh coffee. LED ashing means freshness expired. LED off means warmer off.

Brew Count Total

Press ¤ to Select, Shows total gallons and total brew cycles on the unit. Cannot be reset.

Cold Brew Lock . . . (Factory set to 5º )

Press ¤ to select, < or > to select desired setting (CBL 5, 15 or OFF),¤to set.

The Cold Brew Lock feature allows the brewer to brew at three different temperature levels from the actual set point. The

rst setting is within 5 degrees of set point, next is within 15 degrees of set point, OFF is within 30 degrees of set point for

the Ready to Brew message, however, it will brew at any temperature.

Master Reset

Press ¤ to display Are You Sure?

Then < for Yes, > for No. Brewer factory defaults are then reset.

Service Call (Phone number Factory set to 1-800-000-0000 X0000)

Press ¤ to display number and change number or < to move place and EX to exit when complete. This number will be

displayed during a Heating system SENSOR ERROR or during a WATER ERROR.

Access Code (Factory set to 1-2-3-4)

Press ¤ to display number and change number, (the number can be changed 1 to 4) or < to move place and EX to exit

when complete.

Banner Name (Factory set to CURTIS)

Press ¤ to display letters and change letters or < to move place and EX to exit when complete

This feature allows up to 14 letters to be programmed for company name or regional name. Programming all blanks dis-

ables Banner Name. If programmed, Banner Name is displayed every 5 sec. on and off.

Warmers Auto – Off (Factory set to 10 Hrs.)

Press ¤ to select < or > to adjust from 1-12 hours. This feature has higher priority than the Quality Timer. It shuts off the

warmers after a pre-determined time factory set at 10 hours starting when the Brew Button is pushed. The Quality Timer

does not affect this function.

GLOBAL RECIPES

Global Recipes (Factory set to Gourmet STD)

Press ¤ to select. If selected, press < or > to choose a recipe based on the type of coffee being brewed. Selections are

Gourmet STD, Light Roast, Dark Roast, High Yield, Filter Pack, or Decaf. Press ¤ to select the desired recipe.

WarmersAuto-Off

5

Program Menus GEMIF Brewer

P-Maintenance

BrewByTime

BrewByVolume

Displ.BrewTime

Pre-infusion

PulseBrew

P-Maintenance (Factory set to OFF)

Press ¤ to Select, Set gallons brewed to indicate P-Maintenance. Press < or > to adjust from Off to 9500 gallons. This

feature advances in 100 gallon increments. Press ¤to exit.

Beeper On/Off (Factory set to ON)

Press ¤ to display ON or OFF. Pressing either < or > toggles between on and off. ¤ to set. When ON, this feature allows

you to hear a short beep each time a button is pressed.

Drip-out Mode (Factory set to 2 minutes)

Press ¤ to Select. Press < or > to move to desired time. Settings are OFF, 1, 2, 3, 4 and 5 minutes. Press ¤to Select

time.

Warmers Default (Factory setting - MED)

Press ¤ to Select. Press < or > to adjust from OFF, HIGH (185ºF), MED (182ºF) or LOW (178ºF). These temperatures

are ±3ºF.

Displ. Brew Time (Factory set to ON)

Press ¤ to display ON or OFF. Pressing either < or > toggles between on and off. After Display Brew Time an EXIT screen

will return you to Non-Brew Prog.

Display Messages (Factory set to On)

Display Messages allows the operator to change the screen display to read “Rinse Server Before Brewing” or to turn it off.

Press ¤ to display ON or OFF. Pressing either < or > toggles between on and off. ¤to set.

Display Timers (Factory set to OFF)

Press ¤ to display ON or OFF. Pressing either < or > toggles between on and off. This feature allows the operator to turn

off or on the display for the Quality Timer count-down. At the same time, it also turns off or on the audible alarm. Press ¤to

set and exit.

Drip-outMode

BeeperOn/Off

WarmersDefault

BREW BUTTON PROGRAMMING

Brew by Volume (Factory settings: LARGE 200oz ±8oz. MEDIUM 132oz±4oz. SMALL 64oz±4oz.)

Press ¤ to Select. Display will ask you to select a brew button, Large, Medium or Small. Press the desired brew button to

begin... when desired volume is reached press the same brew button to stop the ow. Now the volume has been set.

Brew by Time (Factory settings: LARGE 5min-25sec. MEDIUM 3min-32sec. SMALL 1min-52sec.)

Next item in the sequence is Brew by Time. Press ¤ to Select to change the brew time. Display will now show the current

time. By pressing < or > you can toggle back and forth from minutes to seconds to exit (ex). Change the time or set and exit

by pressing the ¤button.

Pre-Infusion (Factory Disabled)

Press ¤ to Select. Current setting in seconds is displayed < to decrease or select > to increase (range from OFF to 10

through 60 seconds), ¤to set.

If Pre-infusion is selected (ON), Cold Brew Lock is set within 5ºF of set point and Cold Brew Lock disappears from the list of

program selections. When Pre-infusion is ON, Pulse Brew disappears from the list of program selections.

Pulse Brew (Factory setting C)

Press ¤ to select, < or > to select OFF or one of ve pulse patterns (A to E) . The ve Pulse Brew options help “tune” or

change the coffee avor.

Guidelines for Pulse Brew:

Filter Pack type coffees typically extract better with the Aand B pulse setting.

Decaf coffees typically extract better with the B pulse setting.

High-Yield coffees typically extract better with the C pulse setting. Of course, any of the A, B or Csettings may be used to

suit your taste prole.

Settings Dand E are manual pulse counts.

To exit from the Pulse Brew mode, select 0for the time.

If Pulse Brew is on, Cold Brew Lock is set within 5ºF of set point and Cold Brew Lock disappears from the list of program

selections. When Pulse Brew is on, Pre-infusion disappears from the list of program selections.

DisplayMessages

DisplayTimers

6

Error Message

Anerrormessagewillappearonthe

screen in the event of a malfunction

underthefollowingconditions:

1.Waterleveloverow.

2.Breakintemperaturecontrol

circuit.

3.Excesstemperatureinheating

tank

4. Scalebuild-uponliquidlevel

probe,insidetheheatingtank.*

Toturnoffanerrormessage,pressthe¤buttonforveseconds.

*TheScaleerrorfeatureswillbeginappearinginlaterversionsofGEMIntellifreshbrewers.

Warmers

Thewarmer,withinthesatellitewillturnonautomaticallywhenthecoffeebrewcyclestarts.Thewarmersmaybeswitchedonandoffusingthe

WARMERbuttonsonthecontrolpaneloftheGEMIFbrewer.

TransferringanIntelliFreshsatellitefromthecoffeebreweraremotestandwillnotaffecttheQualityTimersetting.

ModelSelect

Model Select (Factory set to Gemini-Twin IF)

Press ¤ to select, < or > to select model. The selections are: ThermoPro-Twin, ThermoPro-Single, Gemini-Twin, Gemini-

Single, Milano-Twin, Milano-Single, Gemini-Twin IF, and Gemini-Single IF. Press ¤ to set. When the Model Select feature is

changed, all settings are reset to the defaults of the newly selected model. Also, the next feature Batch Select appears.

Batch Select (Factory set to One Batch)

Press ¤ to select, < or > to select One Batch, Two Batch or Three Batch. Press ¤ to set. Display exits programming mode

and returns to normal operation.

Program Menus GEMIF Brewer

Language (Factory set to English)

Press ¤ to Select. Press < or > to move to English or French. This feature is programmable for changing and adding

languages.

Language

By-Pass (Factory settings: LARGE 35%. MEDIUM 10%. SMALL Off.)

The By-Pass option helps with controlling extraction with larger brews. Contact time that is too long will extract undesirable

bitter, harsh avor compounds. By-passing some of the brew water around the coffee bed will balance the extraction.

Press ¤ to display current setting. Press < or > to change settings; OFF, 5% to 50%, in 5% increments. Press ¤to set.

By-Pass

7

GEMTIF

Rough-In Drawings

GEMSIF

8

1

2

3

4

5

32

19

6

7

8

9

10

11

12

42

13

39

15

17

18

43

44

45

20

21

22

30

31

25

26

23

27

24

28

29

33

34

35

41

36

46

537

16

14

40

38

47

Illustrated Parts List

GEMTIF

9

Illustrated Parts List

GEMTIF DESCRIPTIONINDEX Nº PART Nº

* SUGGESTED PARTS TO STOCK

1

2

3

4

5

6

7

8

8A

9

10

11

12

13

13A

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

42A

43

44

45

46

47

GEM3IF

WC-37121*

WC-442

WC-2977-101K*

WC-844-101*

WC-39744

WC-37388*

WC-39755*

WC-39756*

WC-29050*

WC-8559*

WC-3417*

WC-39745

WC-61960

WC-61960-BLK

WC-61963

WC-38504

WC-61962

WC-37008*

WC-43067*

WC-5527K*

WC-934-04*

WC-4382*

WC-1438-101*

WC-62033

WC-29044

WC-2402P*

WC-847 *

WC-37122 *

WC-1501*

WC-102*

WC-522 *

WC-43055*

WC-61955

WC-3528 *

WC-1809*

WC-5310*

WC-5231*

WC-3765L*

WC- 571K-R

WC- 571K-L

WC-43133

WC-5350*

WC-61954

WC-61954-BLK

WC-37266*

WC-37317*

WC-37365*

WC-37132*

GEM-6

SATELLITE, INTELLIFRESH

DUMP VALVE LEFT

SOLENOID, LOCK BREW CONE RIGHT 120V

KIT, SPRAY HEAD FITTING, GASKET, & JAM NUT

VALVE, BY-PASS, NON-ADJUSTABLE W/RSTRCTR

LABEL, UCM & OUTER 3-BATCH GEM-IF

KIT, LABEL & UCM GEMTIF 3-BATCH CURTIS

LABEL, UCM OVERLAY 1-BATCH

LABEL, UCM OVERLAY 2-BATCH

SPRAY HEAD, AFS-AMBER

RELAY, SOLIDSTATE 40A W/HEAT SINK

BREW CONE, ASSY W/SPLASH POCKET BROWN COFFEE

LABEL, BOTTOM PANEL

COVER, FRONT WELD ASSEMBLY SS

COVER, FRONT WELD ASSEMBLY BLACK POWDER COAT

HOLDER, IF CONNECTORS FEMALE GEMTIF

LABEL, WARNING SHOCK HAZARD

DECK, WARMER WELD ASSY

KIT, TANK LID ROUND

O’RING, 4.5” ID SILICONE

KIT, PROBE, ASSY WATER LEVEL W/FITTING, O-RING, NUT

ELEMENT HEATING 2.5KW 220V

GUARD, SHOCK HEATING ELEMENT

SENSOR, HEATING TANK

TANK, COMPLETE GEMTS NON-METAL FITTINGS

SLEEVE, OVERFLOW ASSY GEN USE

ELBOW, 3/8”FL x 3/8” NPT PLATED

VALVE, INLET 2 GPM 120V 10W GEN USE YEL BODY

DUMP VALVE RIGHT

FUSE HOLDER ASSY W/5A FUSE

SWITCH, RESISTIVE TOGGLE NON-LIT SPST 125/250VAC

THERMOSTAT, RESET

GUARD, SHOCK RESET T-STAT

COVER, TOP SS

LEG, 4” ADJUST 3/8-16 THREAD STYLIZED

FAUCET, PS/HPS SERIES HOT WTR

TUBE, 5/16 ID x 1/8W SILICONE

COMPOUND, SILICONE

KIT, VALVE REPAIR USE ON WC-847

KIT, IF CONNNECTOR-RIGHT

KIT, IF CONNECTOR- LEFT

O-RING, 1.424ID X 1.630 OD X .103 WALL GEMIF’s

TUBE, SILICONE Ø1/2” ID x Ø3/4” OD x 1/8” WALL

PLATE, BREWCONE STOP STAINLESS STEEL

PLATE, BREW CONE STOP BLACK POWDER COAT

KIT, TANK OVERFLOW FITTING WITH BUSHING

KIT, STRAIGHT FITTING WITH BUSHING

KIT, TANK INLET FITTING WITH BUSHING

KIT, VALVE REPAIR USE ON WC-844-101

FILTER, 500/PKG

10

Electrical Schematic

GEMTIF

11

5

6

7

8

9

10

11

12

14

40

36

16

17

18

19

20

21

22

25

23

24

26

27

28

29

30

31

32

33

1

2

43

3

4

34

37

38

39

42

7

13

15

35

Illustrated Parts List

GEMSIF

12

Illustrated Parts List

GEMSIF

1

2

3

4

5

6

7

8

9

9A

9B

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

SATELLITE, INTELLIFRESH

COVER, TOP

DUMP VALVE RIGHT

KIT, SPRAY HEAD FITTING, GASKET, & JAM NUT

BREW CONE, ASSY W/SPLASH POCKET BROWN COFFEE

SOLENOID, LOCK BREW CONE L/R LABEL

VALVE BY-PASS NON-ADJUSTABLE

KIT, LABEL & UCM GEMSIF 3-BATCH CURTIS

LABEL, UCM PANEL 3-BATCH GEMSIF

LABEL, UCM PANEL 2-BATCH GEMSIF

LABEL, UCM PANEL 1-BATCH GEMSIF

RELAY, SOLIDSTATE 40A W/HEAT SINK

COVER, FRONT

LABEL, BOTTOM WRAP GEMSIF

FAUCET, PS/HPS SERIES HOT WATER

HOLDER, IF CONNECTOR

LEG, 4” ADJUST 3/8-16 THREAD STYLIZED

DECK, WARMER W/A

ELBOW, 3/8”FL x 3/8” NPT PLATED

FUSE HOLDER ASSY W5A FUSE

PANEL, BACK GEMSS

SWITCH, TOGGLE NON-LIT DPST 25A 125/250VAC RST

VALVE, INLET 2 GPM 120V 10W GEN USE YEL BODY

SPRAY HEAD, AFS-AMBER

COVER, TOP HEATING TANK

GASKET, TANK LID

KIT, PROBE, ASSY WATER LEVEL W/FITTING, O-RING, NUT

TANK, COMPLETE GEMSS W/ULTEM FITTINGS

KIT,ELEMENT, HEATING 1.6KW120V W/JAM NUT, WASHERS

SENSOR, HEATING TANK

GUARD, SHOCK HEATING ELEMENT

THERMOSTAT, RESET

GUARD, SHOCK RESET THERMOSTAT

TUBE, 5/16 ID x 1/8W SILICONE

COMPOUND, SILICONE

KIT, VALVE REPAIR

KIT, IF CONNNECTOR-RIGHT

LABEL, WARNING SHOCK HAZARD

KIT, TANK OVERFLOW FITTING WITH BUSHING

KIT, STRAIGHT FITTING WITH BUSHING

KIT, TANK INLET FITTING WITH BUSHING

O-RING, 1.424ID X 1.630 OD X .103 WALL GEMIF’s

SLEEVE, OVERFLOW ASSY GEN USE (NOT SHOWN)

KIT, BY-PASS VALVE USE ON WC-844-101

FILTER, 500PK 12½ x 4

* SUGGESTED PARTS TO STOCK

GEM3IF

WC-61928

WC-37122*

WC-2977-101K*

WC-3417

WC-442

WC-844-101*

WC-37389

WC-39801*

WC-39802*

WC-39803*

WC-8559*

WC-61927

WC-39800

WC-1809*

WC-61963

WC-3528 *

WC-61930

WC-2402P*

WC-1501

WC-59020

WC-103*

WC-847 *

WC-29050*

WC-5853-102

WC-43062*

WC-5527K*

WC-62035

WC-904-04*

WC-1438-101*

WC-4394*

WC-522 *

WC-43055*

WC-5310*

WC-5231*

WC-3765L*

WC-571K-R

WC-38504

WC-37266*

WC-37317*

WC-37365*

WC-43133

WC-29044

WC-37132*

GEM-6

DESCRIPTIONINDEX Nº PART Nº

13

Electrical Schematic

GEMSIF(-10Only)

14

2

3

4

5

6

1

7

11

10

12

13

16

18

19

8

9

14

20

15

17

A

Illustrated Parts List

GEM3IF

15

Illustrated Parts List

GEM3IF

Rough-In Drawing

GEM3IF

* SUGGESTED PARTS TO STOCK

** FOR UNITS BUILT AFTER 3/2015

1

2

3

4

5

6

7

8

9

10

11

11A

12

13

13A

14

15

16

17

18

19

20

WC-5622*

WC-2001

WC-2005*

WC-2025*

WC-2010C

WC-2006*

WC-2102

WC-39747

WC-2007

WC-6417

WC-1901A

WC-1901A-103K **

WC-1800*

WC-37543*

WC-37552 **

WC-37544*

WC-39746

WC-37545*

WC-3705*

WC-38151

WC-13426

WC-39747

LID, BLACK PLASTIC GEM-3

CAP, SHIELD W/VENT

WASHER, SHIELD CAP 1/8”

GLASS, GAUGE 8”

SHIELD, GAUGE GLASS ¾” D. x 8”

WASHER, .188ID x .188 THK BOTTOM

GAUGE GLASS ASSEMBLY 8”

LABEL, SIDE GEM3IF CURTIS LOGO

BRACKET, GAUGE GLASS GEM-3

GUARD, FAUCET GEM-3

SHANK, FAUCET W/SHIELD BASE

KIT, SHANK ASSY, FAUCET W/ SHIELD BASE & O-RING

FAUCET, S’ SERIES NON-LOCKING

KIT, INTELLIFRESH HEATER GEM3IF

KIT, INTELLIFRESH HEATER WC-981 GEM3IF

KIT, RED LED LIGHT GEM3IF

LABEL, FRONT GEM3IF CURTIS LOGO

KIT, HYBRID TEMPERATURE CONTROL

KIT, FAUCET S’ SERIES

LABEL, LOCK/UNLOCK GEM3

IF CONNECTOR, FEMALE W/WIRES

LABEL, SIDE GEM-3IF CURTIS LOGO

DESCRIPTIONINDEX Nº PART Nº

16

Electrical Schematic

GEM3IF

Regularcleaningofyourcoffeebrewerwillmaintainthehighestqualitycoffeeyourequipmentiscapableofproducing.Apropercleaningis

essentialinpreservingtheappearanceandperformanceofthebrewer.

CAUTION:DONOTuseundilutedbleachorchlorine.

1. Turn off the unit at the button on the front control panel.

2. Wipeexteriorsurfaceswithadampcloth,removingspillsanddebris.

3. Slidethebrewconeoutandcleanit.Thoroughlysoapthesprayheadareawithamilddetergentsolution.

4. Washthebrewbasket.Useasoftbristledbrushforhardtocleanareas.Washbothpartswithadetergentsolutionorputtheseparts

throughadishwasher.

Cleaning

17

CAP

WASHER

GLASS TUBE

WASHER

SEAT

CUP

WARNING: Disconnect electrical power before removing access panels!

CAUTION: This procedure involves working with hot water and hot surfaces!

A daily routine of cleaning the GEM3IF Satellite will maintain the appearance of the unit and ensure great tasting cof-

fee. To clean the Satellite components, prepare a mild solution of detergent and warm water.

CAUTION – Do not use cleansers, liquids containing bleach, powders or any other substance containing chlo-

rine. These products promote corrosion and will pit the stainless steel. USE OF THESE PRODUCTS WILL

VOID THE WARRANTY.

Cleaning the Gem3IF Satellite

Cleaning the Satellite Server

DO NOT immerse the Satellite in water or any other liquid.

1. Remove lid from Satellite. Clean the lid at the funnel area with a spiral brush and detergent solution.

2. Rinse the lid, removing all traces of cleaning solution.

3. Clean inside of the Satellite. Remove coffee residue with the detergent solution.

4. Thoroughly rinse out the Satellite with clean warm

water.

5. Unscrew the handle/bonnet assembly and remove it

from the dispensing faucet.

6. Inspect the silicone seat cup for wear, cracks, or

hardening. If okay, then leave the seat cup attached

on the handle/bonnet assembly. Soak then wipe

clean. Replace the seat cup if damaged.

7. Remove the gauge glass tube by unscrewing the

gauge glass cap.

8. Clean the gauge glass tube with a gauge brush

soaked with detergent solution. Soak and wipe the

two washers. Rinse with clean water. Dry the parts

and assemble them onto the Satellite. Hand tighten

the cap.

9. Clean all parts. Thoroughly rinse with clean warm

water.

10. Dry and assemble the parts. Hand-tighten when the

assembling.

Liquid Level Probe

Cleaning intervals for the probe are to be determined by the user or the service tech based on water conditions. The

use of water lters, or the type of water lter that is being used can impact the service interval. Intervals can be from

one month to several years, however, replacing rather than cleaning the probe is preferable.

1. Unplugthepowercordandshutoffthewaterline.

2. Removethetopcoveroftheunit.Locatethetopofthetankandremovethecover.

3. Drainthetanktoalevelabout3”belowthetipoftheprobe.

4. Allowsometimefortheprobetocoolbeforeworkingonthebrewer.

5. CleanthetipoftheprobeusingaScotch-Brite™scuffpad.

6. Ifaresidualwhitelayerisstillvisibleontheprobe,removetheprobeandsoakitinvinegarorascaleremovingchemical.Repeatthisstep

untilthewhitelayerisremoved.

18

ECN16212.10/10/[email protected]revJ

ECN14810.3/6/[email protected].revH

ECN14475.10/17/[email protected].revG

ECN14401.8/29/12@13.5.revF

ECN13971.4/2/12@15.5

ECN12835.12/27/[email protected]

ECN12640.9/30/[email protected]

ECN12400.6/15/10@12.7

edr7091.3/23/10@12.2

Printed in U.S.A. 10/2014 . F-3691 . rev J

WILBUR CURTIS CO., INC.

6913AccoSt.,Montebello,CA90640-5403USA

Phone:800/421-6150 Fax:323-837-2410

TechnicalSupportPhone:800/995-0417(M-F5:30A-4:00PPST) E-Mail:[email protected]

WebSite:www.wilburcurtis.com

ProductWarrantyInformation

TheWilburCurtisCompanycertiesthatitsproductsarefreefromdefectsinmaterialandworkmanshipundernormaluse.Thefollowinglimited

warrantiesandconditionsapply:

3 Years,PartsandLabor,fromOriginalDateofPurchaseondigitalcontrolboards.

2 Years,Parts,fromOriginalDateofPurchaseonallotherelectricalcomponents,ttingsandtubing.

1 Year,Labor,fromOriginalDateofPurchaseonallelectricalcomponents,ttingsandtubing.

Additionally,theWilburCurtisCompanywarrantsitsGrindingBurrsforForty(40)monthsfromdateofpurchaseor40,000poundsofcoffee,

whichevercomesrst.StainlessSteelcomponentsarewarrantedfortwo(2)yearsfromdateofpurchaseagainstleakingorpittingandreplace-

mentpartsarewarrantedforninety(90)daysfromdateofpurchaseorfortheremainderofthelimitedwarrantyperiodoftheequipmentinwhich

the component is installed.

Allin-warrantyservicecallsmusthavepriorauthorization.ForAuthorization,calltheTechnicalSupportDepartmentat1-800-995-0417.Effective

dateofthispolicyisApril1,2003.

Additional conditions may apply. Go to www.wilburcurtis.comtoviewthefullproductwarrantyinformation.

CONDITIONS & EXCEPTIONS

Thewarrantycoversoriginalequipmentattimeofpurchaseonly.TheWilburCurtisCompany,Inc.,assumesnoresponsibilityforsubstitutereplace-

ment parts installed on Curtis equipment that have not been purchased from the

WilburCurtisCompany,Inc.TheWilburCurtisCompanywillnotacceptanyresponsibilityifthefollowingconditionsarenotmet.Thewarranty

doesnotcoverandisvoidunderthefollowingcircumstances:

1) Improper operation of equipment: The equipment must be used for its designed and intended purpose and function.

2) Improper installation of equipment: This equipment must be installed by a professional technician and must comply with all local electrical,

mechanical and plumbing codes.

3) Improper voltage: Equipment must be installed at the voltage stated on the serial plate supplied with this equipment.

4) Improper water supply: This includes, but is not limited to, excessive or low water pressure, and inadequate or uctuating water ow

rate.

5) Adjustments and cleaning: The resetting of safety thermostats and circuit breakers, programming and temperature adjustments are the

responsibility of the equipment owner. The owner is responsible for proper cleaning and regular maintenance of this equipment.

6) Damaged in transit: Equipment damaged in transit is the responsibility of the freight company and a claim should be made with the car-

rier.

7) Abuse or neglect (including failure to periodically clean or remove lime accumulations): Manufacturer is not responsible for variation

in equipment operation due to excessive lime or local water conditions. The equipment must be maintained according to the manufacturer’s

recommendations.

8) Replacement of items subject to normal use and wear: This shall include, but is not limited to, light bulbs, shear disks, “0” rings, gaskets,

silicone tube, canister assemblies, whipper chambers and plates, mixing bowls, agitation assemblies and whipper propellers.

9) Repairs and/or Replacements are subject to our decision that the workmanship or parts were faulty and the defects showed up under normal

use. All labor shall be performed during regular working hours. Overtime charges are the responsibility of the owner. Charges incurred by

delays, waiting time, or operating restrictions that hinder the service technician’s ability to perform service is the responsibility of the owner

of the equipment. This includes institutional and correctional facilities. The Wilbur Curtis Company will allow up to 100 miles, round trip, per

in-warranty service call.

RETURN MERCHANDISE AUTHORIZATION: All claims under this warranty must be submitted to the Wilbur Curtis Company Technical

Support Department prior to performing any repair work or return of this equipment to the factory. All returned equipment must be repackaged

properly in the original carton. No units will be accepted if they are damaged in transit due to improper packaging. NO UNITS OR PARTS WILL

BE ACCEPTED WITHOUT A RETURN MERCHANDISE AUTHORIZATION (RMA). RMA NUMBER MUST BE MARKED ON THE CARTON

OR SHIPPING LABEL. Allin-warrantyservicecallsmustbeperformedbyanauthorizedserviceagent.CalltheWilburCurtisTechnicalSup-

portDepartmenttondanagentnearyou.

This manual suits for next models

2

Table of contents

Other Wilbur Curtis Company Brewing System manuals

Wilbur Curtis Company

Wilbur Curtis Company G4CBHS User manual

Wilbur Curtis Company

Wilbur Curtis Company D1000GT User manual

Wilbur Curtis Company

Wilbur Curtis Company Gemini GEM-612ILD User manual

Wilbur Curtis Company

Wilbur Curtis Company Gem-12D User manual

Wilbur Curtis Company

Wilbur Curtis Company ThermoPro Twin User manual