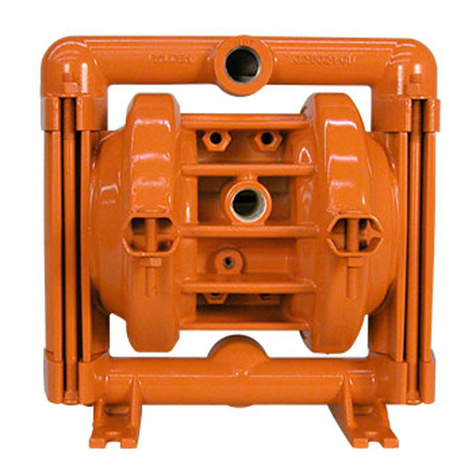

Wilden PX1500 Advanced Series Instruction Manual

Table of contents

Other Wilden Water Pump manuals

Wilden

Wilden Advanced Series Instruction Manual

Wilden

Wilden PS1520 Installation guide

Wilden

Wilden T2 Original Metal User manual

Wilden

Wilden T4 PLASTIC Instruction Manual

Wilden

Wilden P25 Advanced Plastic Series User manual

Wilden

Wilden P400 User manual

Wilden

Wilden PS 8 Stallion Metal Instruction Manual

Wilden

Wilden Original Series Troubleshooting guide

Wilden

Wilden P800 Instruction Manual

Wilden

Wilden Turbo-Flo T8 Instruction Manual

Wilden

Wilden PS400 Instruction Manual

Wilden

Wilden PR460 User manual

Wilden

Wilden Original Series Instruction Manual

Wilden

Wilden P4 series Instruction Manual

Wilden

Wilden H220 Instruction Manual

Wilden

Wilden P2 series User manual

Wilden

Wilden P25 Advanced Plastic Series Instruction Manual

Wilden

Wilden SANFLO PX15 Manual

Wilden

Wilden Turbo-Flo T8 Instruction Manual

Wilden

Wilden Saniflo DUS Instruction Manual

Popular Water Pump manuals by other brands

eta

eta SR Series Use and maintenance manual

Impos

Impos GS 4003 Translation of the original instructions

MULTIQUIP

MULTIQUIP LS600P Operation manual

EINHELL

EINHELL GC-DP 1020 N Original operating instructions

Warren rupp

Warren rupp WR10 3/8" operating instructions

IWAKI PUMPS

IWAKI PUMPS HRP-54V/H-1 instruction manual

Parkside

Parkside PKZ 180 C5 Translation of the original instructions

AdBlue

AdBlue CDI-H27 user manual

Gardena

Gardena WP 1800 operating instructions

Cablematic

Cablematic PC-24A Operation manual

Nagman

Nagman HHP 700 manual

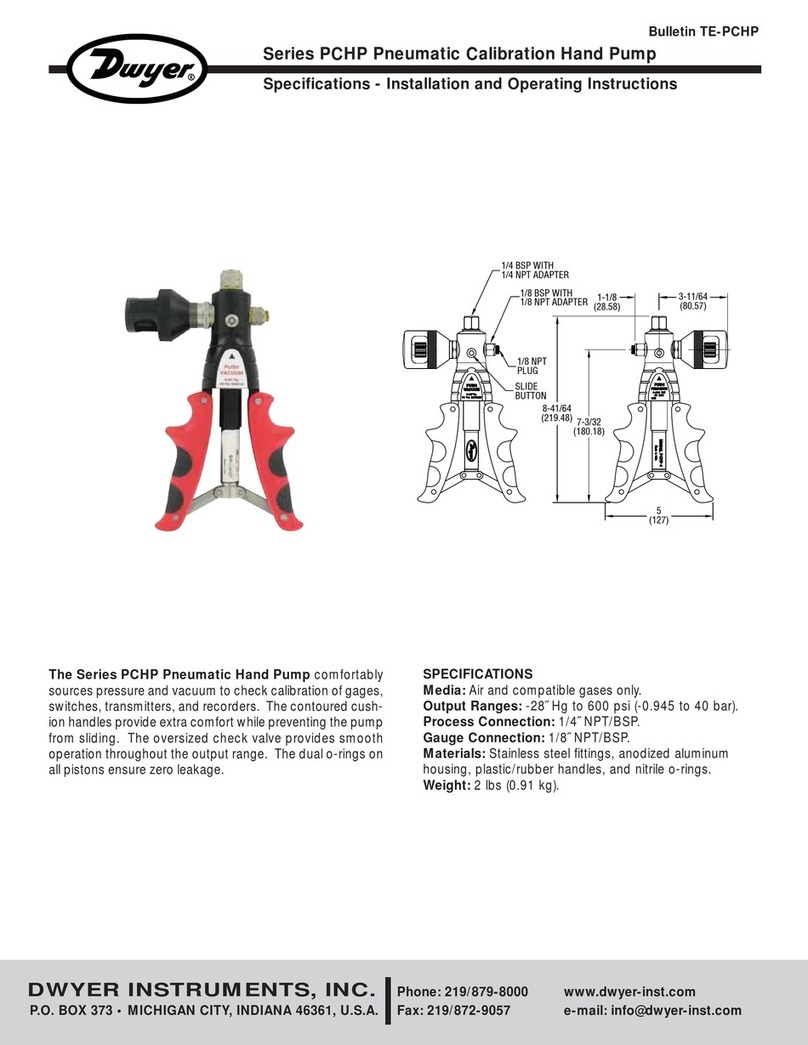

Dwyer Instruments

Dwyer Instruments PCHP Series Installation and operating instructions

Zoeller

Zoeller AQUANOT 508 Fit installation instructions

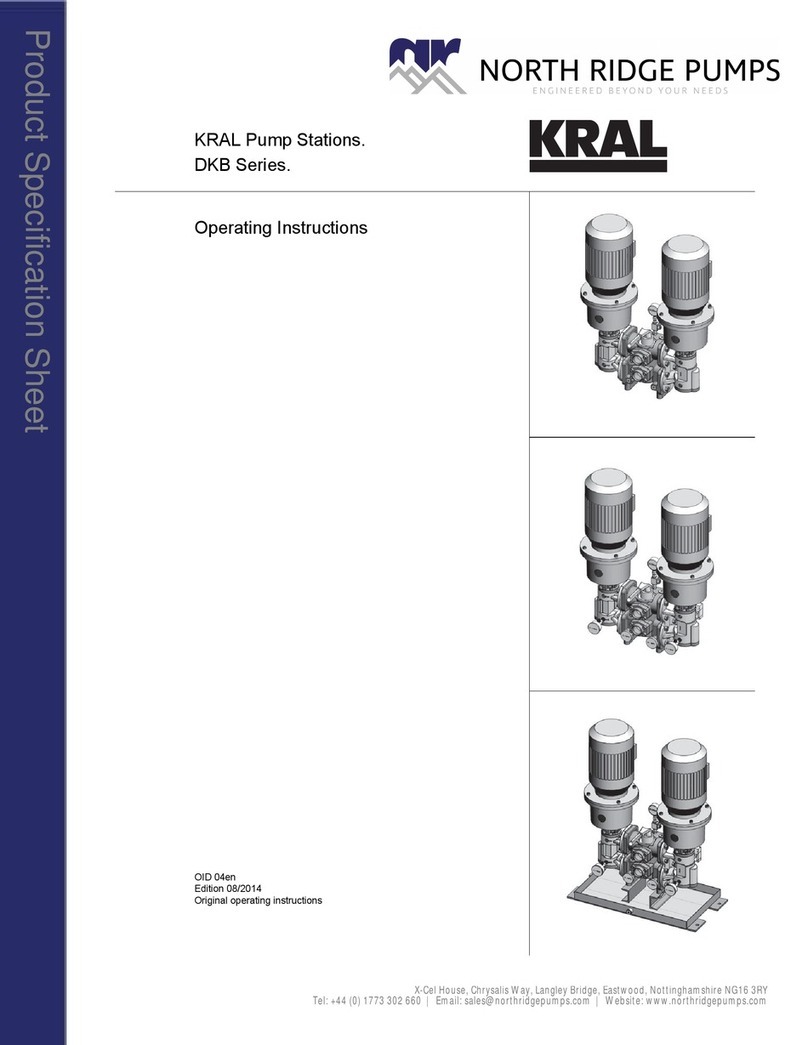

North Ridge Pumps

North Ridge Pumps KRAL DKB Series operating instructions

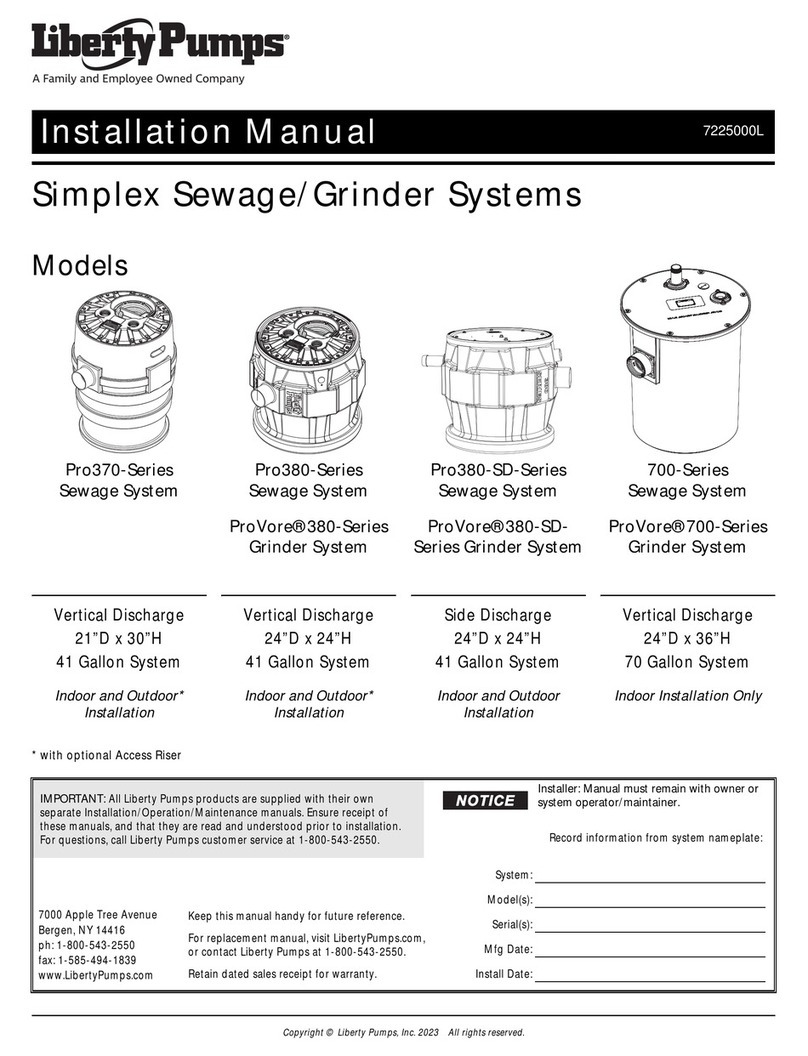

Liberty Pumps

Liberty Pumps Pro380 Series installation manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS T2A60 B Installation, operation, and maintenance manual with parts list

TriboServ

TriboServ FlexxPump4 BXXX-EXT Supplementary sheet

PondXpert

PondXpert FeatureFlow PXFEAT0350B instructions