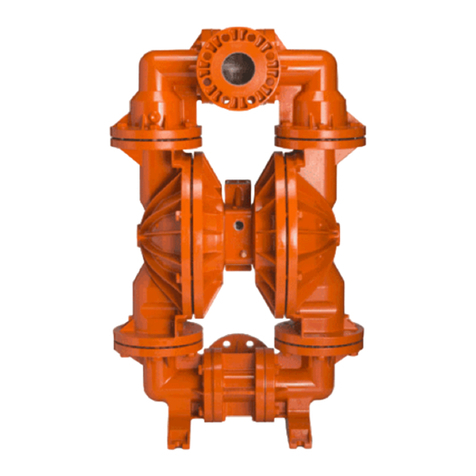

Wilden Advanced Series Instruction Manual

Other manuals for Advanced Series

1

This manual suits for next models

1

Table of contents

Other Wilden Water Pump manuals

Wilden

Wilden Original Series Troubleshooting guide

Wilden

Wilden A2 Original Plastic Series User manual

Wilden

Wilden Advanced Series Instruction Manual

Wilden

Wilden P25 Advanced Plastic Series Instruction Manual

Wilden

Wilden Original Series Troubleshooting guide

Wilden

Wilden PS1520 Installation guide

Wilden

Wilden H800 Troubleshooting guide

Wilden

Wilden Turbo-Flo T8 Instruction Manual

Wilden

Wilden P800 Instruction Manual

Wilden

Wilden Original Series Troubleshooting guide

Wilden

Wilden Pro-Flo P2 Installation guide

Wilden

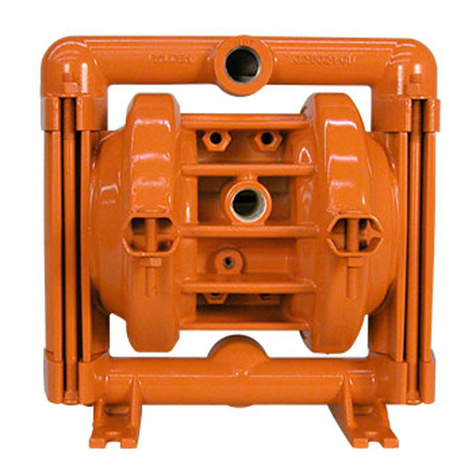

Wilden PS 8 Stallion Metal Instruction Manual

Wilden

Wilden EOM P200 Manual

Wilden

Wilden Original Series Instruction Manual

Wilden

Wilden P2 series User manual

Wilden

Wilden Saniflo PX8 Instruction Manual

Wilden

Wilden Saniflo PS8 Instruction Manual

Wilden

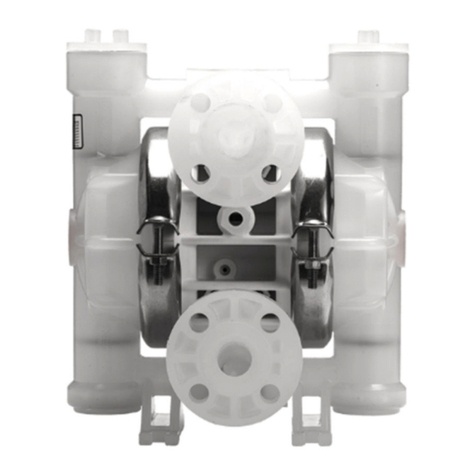

Wilden PS 4 Stallion Metal Instruction Manual

Wilden

Wilden H220 Installation guide

Wilden

Wilden P25 Advanced Plastic Series User manual

Popular Water Pump manuals by other brands

Briggs & Stratton

Briggs & Stratton PROSERIES 205378GS Operator's manual

Grundfos

Grundfos SP Installation and operating instructions

Pentair

Pentair MAX Series manual

BW SOLAR

BW SOLAR Waterboy installation manual

FLOWTECH

FLOWTECH flowboost F.H Operation and maintenance manual

Stanley

Stanley STAPB70 instruction manual