Operating- and Installation Manual B 380 - Hans Wilms GmbH & Co. KG

9. Operation

Starting:

Switch the power button to position "1", if a room thermostat is used, set it to a temperature above the

actually existing room temperature.

The blower motor starts, and after a pre-aeration phase of about 10 seconds, the flame is formed.

Stopping:

Switch the power button to position "0", if a room thermostat is used, set it to a temperature below the actual

room temperature. The device runs time-controlled for about 60 seconds to cool down. Only when the follow-

up is finished, the device may be disconnected from the mains!

Malfunction:

In case of an empty tank, abnormal combustion, dirty photocell, overheating or other defects, the control unit

detects a problem, interrupts the operating process, and indicates a fault caused by permanent red light of

the indicator light. This also serves as a reset button for acknowledging the fault, which is retained even after

the mains voltage has been switched off.

First determine and eliminate the cause of the fault before you disturb the control (by pressing the remaining

button for about 2 seconds).

10. Maintenance

Depending on the conditions of use and frequency of use, the maintenance intervals can be very different.

However, the device should be cleaned at least once a year and tested for function and safety. Maintenance

and repair work should only be carried out by persons with the necessary expertise.

Clean the fan wheel, the burner, the storage disc, the electrodes and the fuel filters in the tank filler neck,

filter housing, fuel pump and nozzle.

Replace defective or worn parts with original spare parts immediately. When ordering spare parts, always

specify the device type and serial number.

During cleaning work, always disconnect the device from the mains and work only on the cooled device.

Note that the device does not burn correctly when the burner cover is open because of the lower amount of

air.

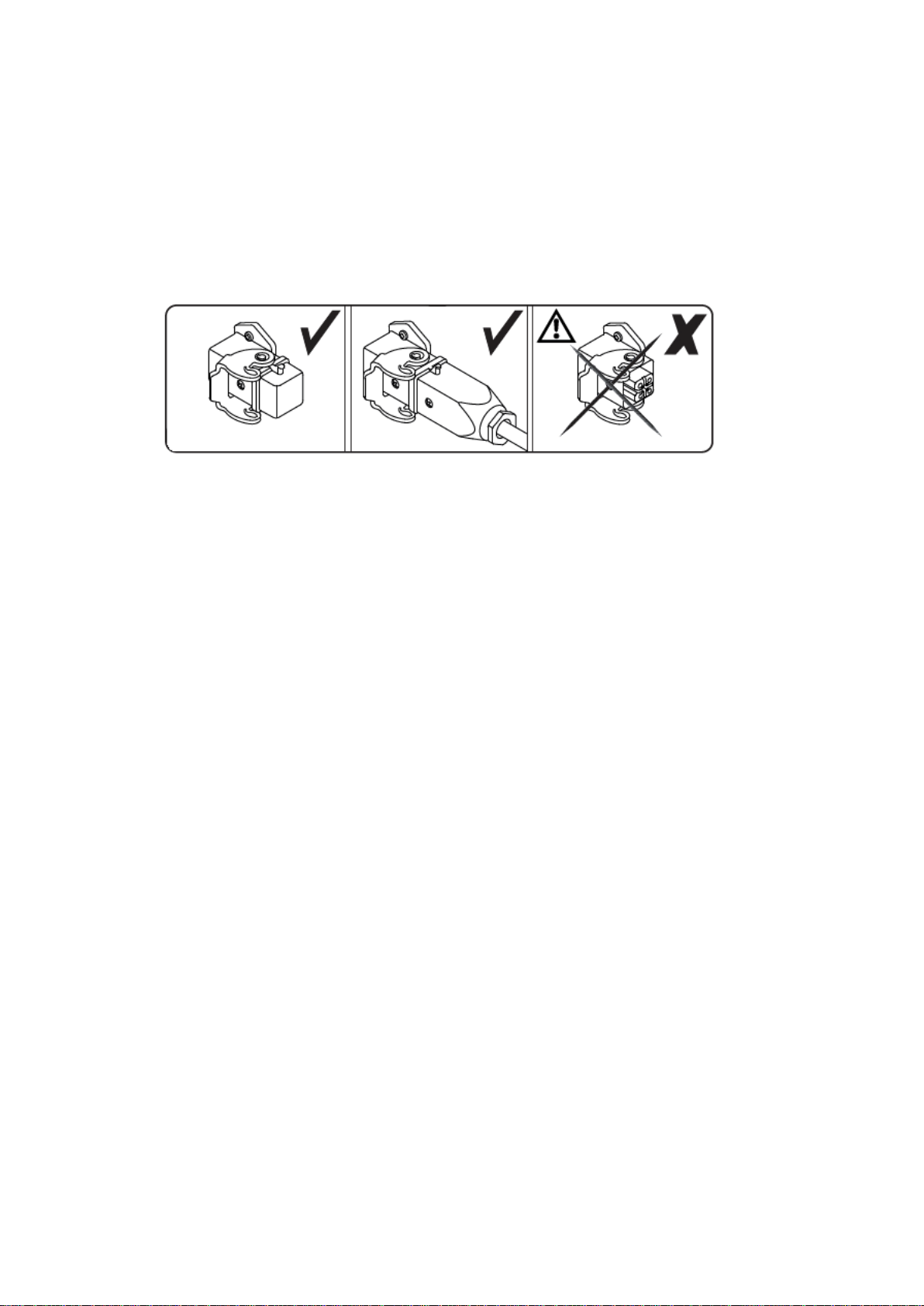

Check the fuel tank and the filter housing A (Fig. 3) for contamination and condensation, and empty and

clean if necessary. Clean the filter insert B with appropriate means or replace it. Check the condition and

correct fit of the seals and replace them if necessary. A repair kit is available for this purpose (spare parts

list).

Check - and correct, if necessary - the adjustment of the air volume (Fig. 4), the oil pressure and the

electrodes (Fig. 5 + 6), and pay attention to the installation of a burner nozzle of the correct type, size and

spray angle. The correct values can be found in the drawings, spare parts lists and technical data.

Page 7 of 15