Aug. Winkhaus GmbH & Co. KG ∙ Hessenweg 9 ∙ 48157 Münster ∙ T +49 251 4908 - 0 ∙ zutrittsorganisation@winkhaus.de ∙ www.winkhaus.de

ETB-IM 2

Operating manual

Table of contents

1 Included in delivery............................................................................................................................................................................................................................ 3

2 Product overview................................................................................................................................................................................................................................4

3 Security..................................................................................................................................................................................................................................................... 5

3.1 Intended use ............................................................................................................................................................................................................................... 5

3.2 Safety information and liability exclusions ................................................................................................................................................................ 5

4 Transport and storage......................................................................................................................................................................................................................6

4.1 Transport and unpacking ....................................................................................................................................................................................................6

4.2 Storage without batteries ...................................................................................................................................................................................................6

4.3 Storage with batteries........................................................................................................................................................................................................... 6

5 Assembly preparation ...................................................................................................................................................................................................................... 7

5.1 Definition of terms................................................................................................................................................................................................................... 7

5.2 Tools ................................................................................................................................................................................................................................................ 7

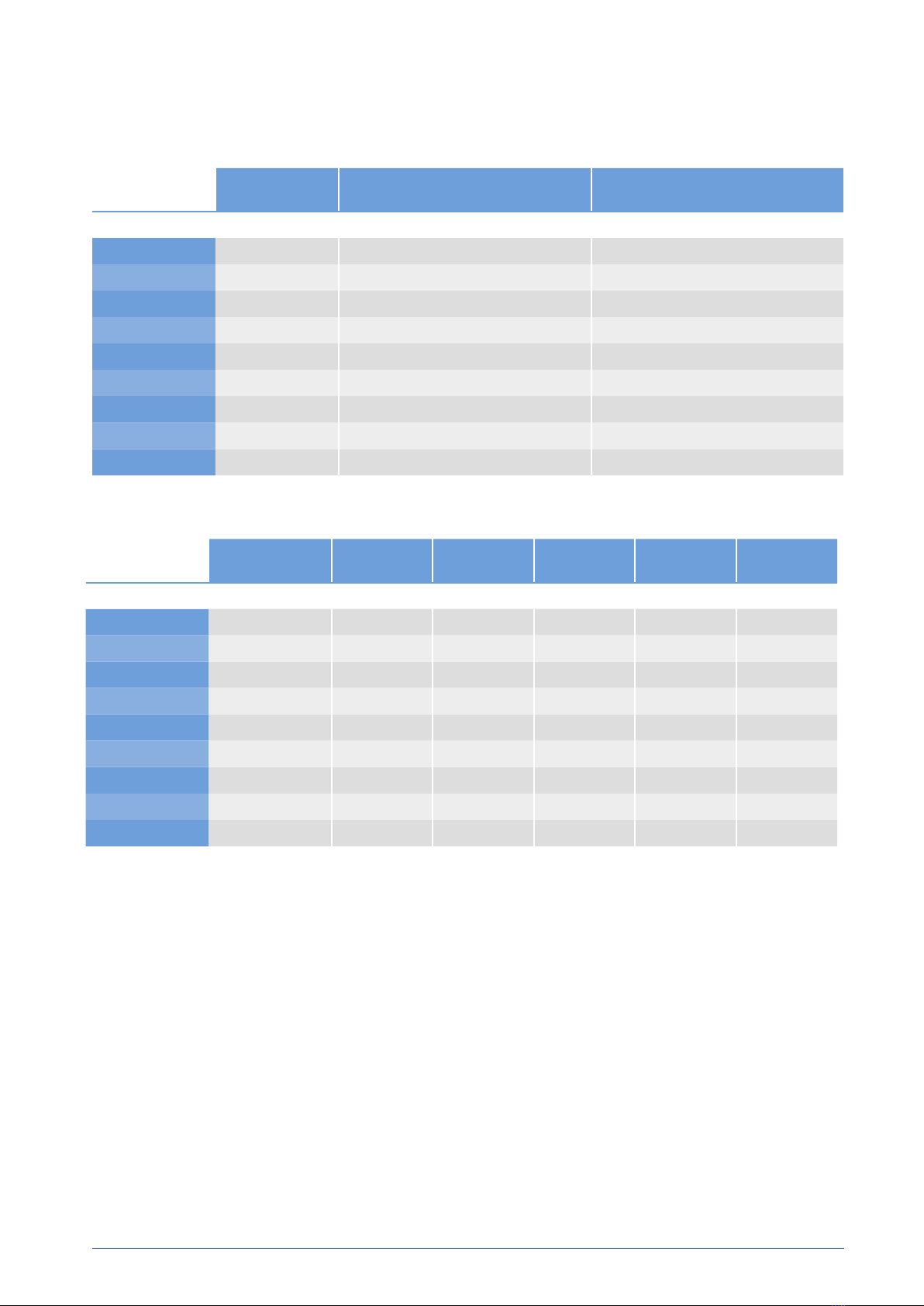

5.3 Door thickness tolerance table ........................................................................................................................................................................................ 8

5.4 Integrating the product in a blueSmart locking system .................................................................................................................................... 9

5.5 Dismantling the old door fitting....................................................................................................................................................................................... 8

5.6 Dismantling the lock and door handle .........................................................................................................................................................................9

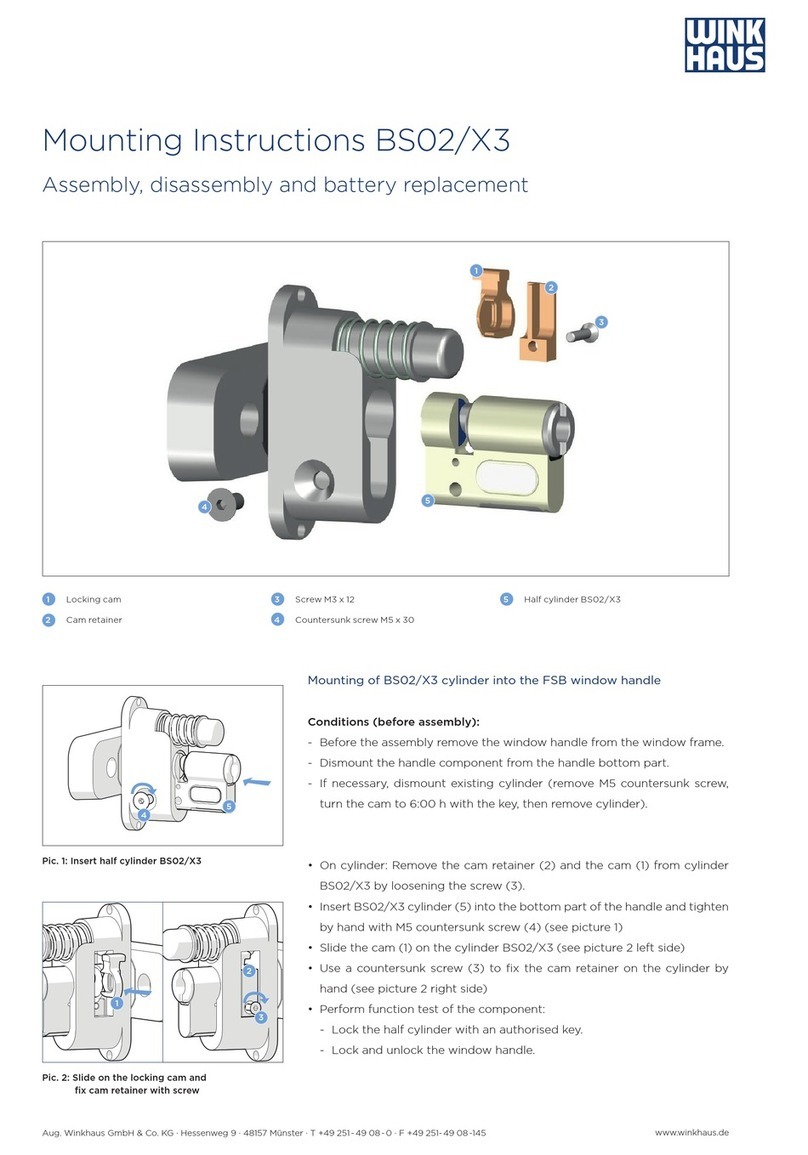

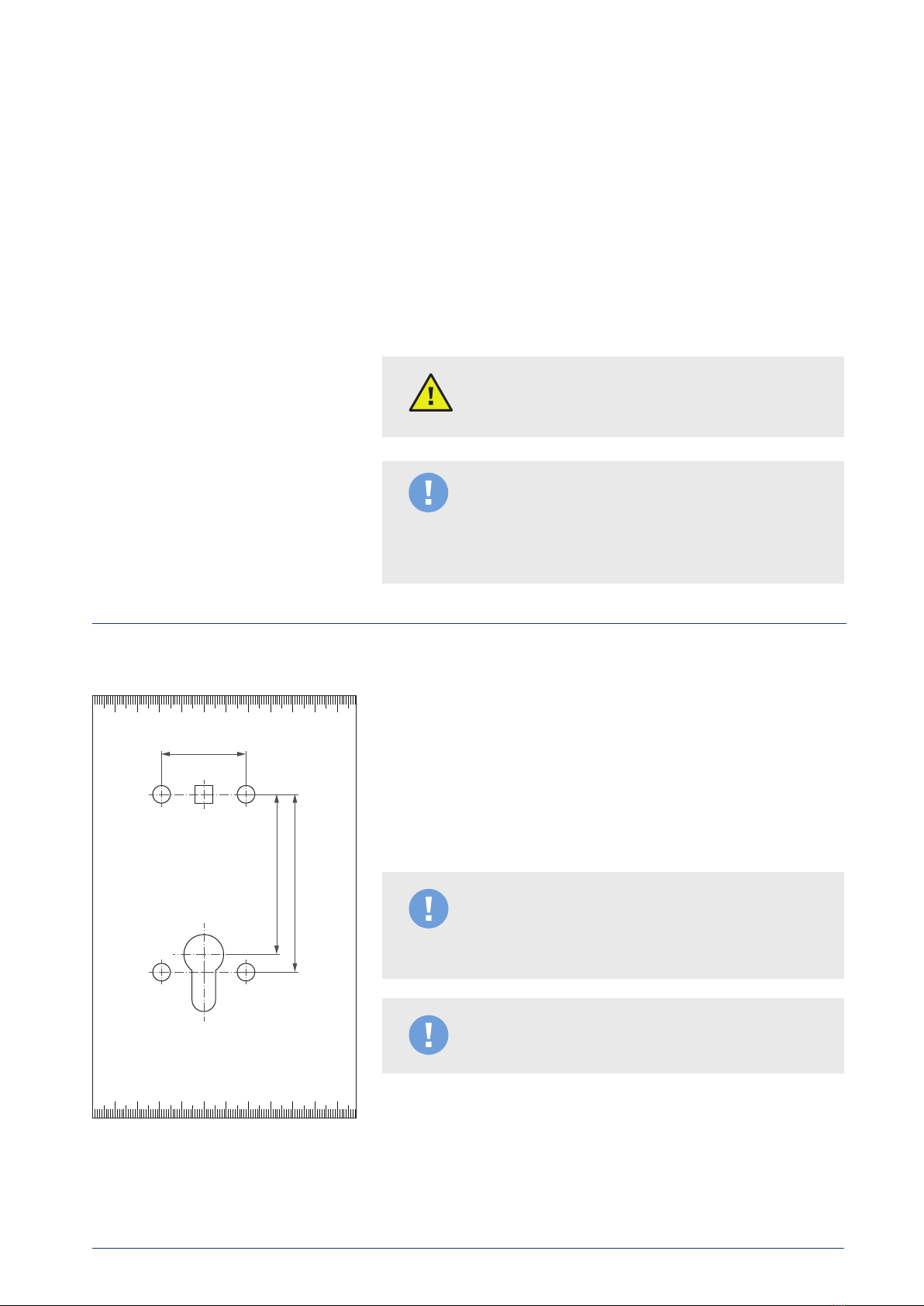

6 Mounting instructions..................................................................................................................................................................................................................... 10

7 Mounting ................................................................................................................................................................................................................................................ 10

8 Functional testing ..............................................................................................................................................................................................................................13

9 Operation............................................................................................................................................................................................................................................... 14

9.1 Identification media.............................................................................................................................................................................................................. 14

9.2 Individual release.................................................................................................................................................................................................................... 14

9.3 Manual permanent release (DFG) .................................................................................................................................................................................15

9.4 Release time.............................................................................................................................................................................................................................. 16

9.5 Permanent release modes ................................................................................................................................................................................................ 16

9.6 Saving of locking events .................................................................................................................................................................................................... 16

9.7 Battery warning messages................................................................................................................................................................................................17

10 Converting from handle left to handle right ...................................................................................................................................................................... 18

11 Cleaning and maintenance .........................................................................................................................................................................................................20

11.1 Cleaning the electronic door fitting ........................................................................................................................................................................... 20

11.2 Replacing the battery.........................................................................................................................................................................................................20

11.3 Carrying out a firmware update ................................................................................................................................................................................... 22

12 Troubleshooting................................................................................................................................................................................................................................ 23

13 Spare parts and accessories...................................................................................................................................................................................................... 24

14 Disassembly .........................................................................................................................................................................................................................................25

15 Disposal instructions for product and packaging ......................................................................................................................................................... 26

16 Technical specifications................................................................................................................................................................................................................ 26