Operating instructions

Winterhalter reverse osmosis unit RoMatik XS

1 Safety notes

In order to operate the RoMatik XS safely, please carefully read the safety notes listed

here.

1.1 Explanation of symbols used

The following symbols have been used in these instructions:

Danger

Warning against potential serious or fatal injuries to persons if the

described precautionary measures are not taken.

Caution

Warning against defects in or destruction of the product if the

described precautionary measures are not taken.

IMPORTANT Important information is given here.

INFO Useful information is given here.

These arrows indicate conduct instructions.

This symbol indicates results of your actions.

This symbol indicates itemisations.

This symbol refers to a chapter with more detailed information.

1.2 Proper use

The RoMatik XS reverse osmosis unit serves for the treatment (demineralisation) of

cold raw water (max. 35 °C) for ultimate use in commercial warewashers. The

RoMatik XS reduces the overall salt content of the raw water. The treated water is

comparable to the purity of distilled water.

The quality of the raw water must conform to the requirements of the German potable

water ordinance. In addition, limits must be respected (9).

The device may only be used in connection with a commercial warewasher.

The device is a technical device for commercial use and is not intended for private

use.

1.3 Improper use

The raw water treated with the RoMatik XS may not be utilized as drinking water.

This device is not intended for use by persons (including children) with limited

physical, sensory or mental capabilities or who do not have the required experience

with and knowledge of this device. Such persons must either be instructed by a

supervisor who is responsible for their safety or must be supervised during the

operation of the device.

Winterhalter Gastronom GmbH does not assume liability or warranty in the event that

the device is used improperly.

1.4 Requirements for the warewasher connected to the device

The RoMatik XS may only be used in connection with a commercial warewasher with

a pressure independent boiler. Operation on warewashers with pressure boilers in

conjunction with a diaphragm pressurised boiler is possible (see Connection

diagram). The yield is reduced, however, and the fill time of the warewasher is

extended.

All components of the warewasher which come into contact with water must be

suitable for osmosis water. Use of non-ferrous metals is not permitted. Only synthetic

components and stainless steel components may be utilized.

1.5 General safety notes

Carefully read the safety notes and operating instructions. Winterhalter Gastronom

GmbH does not assume liability or warranty in case of non-adherence to these safety

notes.

Use the device only after you have read and understood the operating instructions.

Allow the Winterhalter Customer Service Department to provide information about the

operation and function. Always operate the RoMatik XS as described in these

operating instructions.

Train the operating personnel as regards handling the RoMatik XS and inform them

about the safety notes. Repeat the training sessions at regular intervals to prevent

accidents.

Keep the operating instructions accessible.

Do not make changes, additions or reconstructions without the approval of the

manufacturer.

Danger of electric shock: Do not open any covers if it requires tools. Do not

manipulate the electrical components of the device yourself, always call a

professional (electrical technician).

Disconnect the water supply immediately if the device becomes leaky at any location.

Pull the mains plug in order to disconnect the power to the device and close the water

stop cock.

In case of danger and/or defects, switch off the device immediately. Pull the plug.

Only then is the device without power.

Do not insert the plug or pull it out with wet hands.

Pull the plug from the outlet only by the plug, not using the cord.

Contact the Winterhalter Customer Service in case of defects that are not caused due

to the on-site water or electricity supply. Switch on the RoMatik XS again when the

defect has been resolved

For your safety, test the on-site residual-current circuit breaker (FI) regularly by

pressing the test button.

2 Before working with the RoMatik XS

Have the device connected to water supply and the sewer as per the locally

applicable standards and the regulations of the authorised mechanics. For more

information, please see page 8.

Have the device installed and commissioned by an authorised service technician.

Have yourself and your operating personnel trained in the operation of the device.

3 Product description

The water treatment of this device is based on the principle of reverse osmosis

(mechanical filtration). First, the water passes through an active charcoal filter that filters

out chlorine and sediment. The water is then forced at high pressure through two

membranes, so that about 98 % of the content is removed. The treated water is

comparable to distilled water.

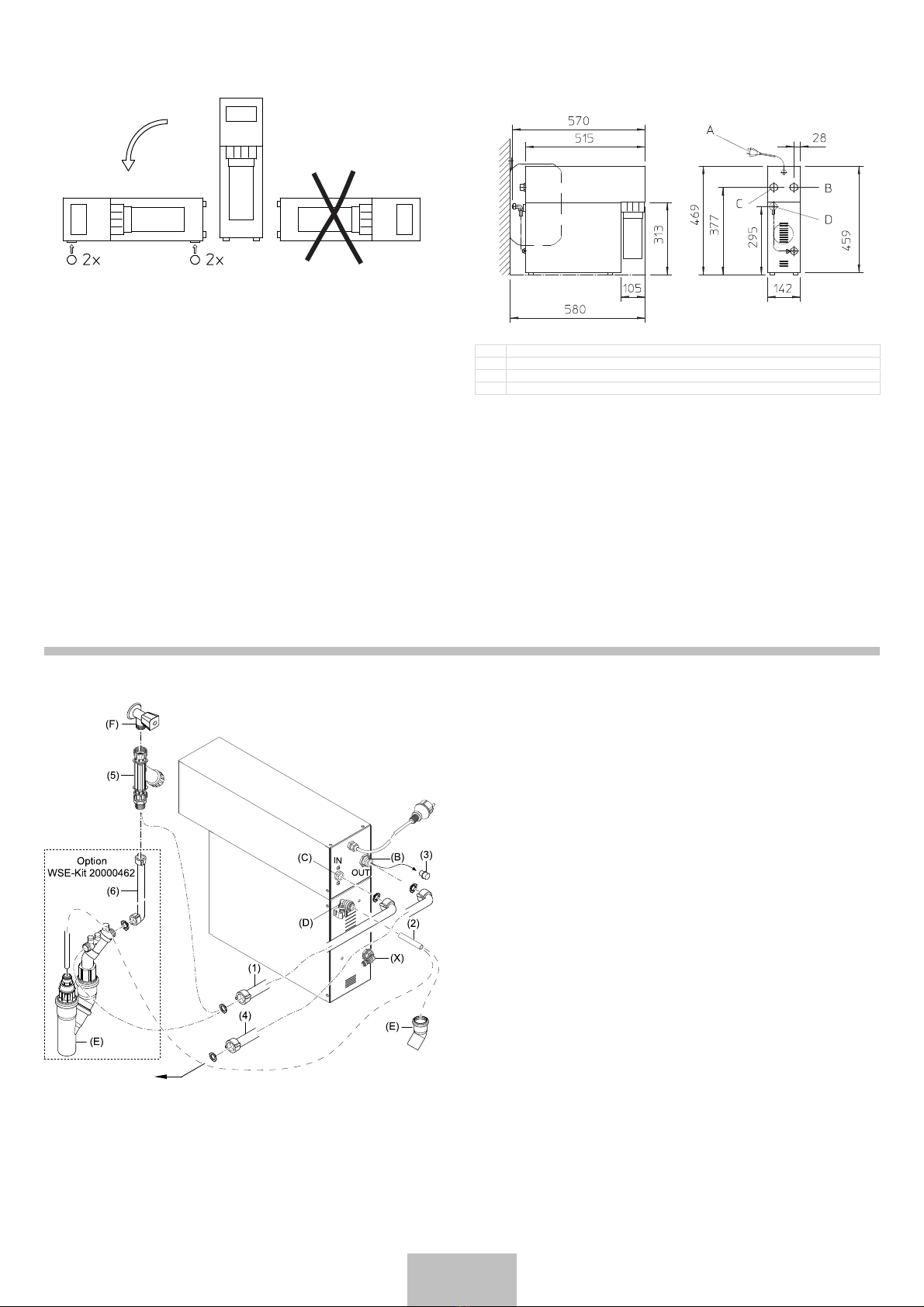

4 Device overview

1 Operating panel

2 Active charcoal filter

3 Capillary

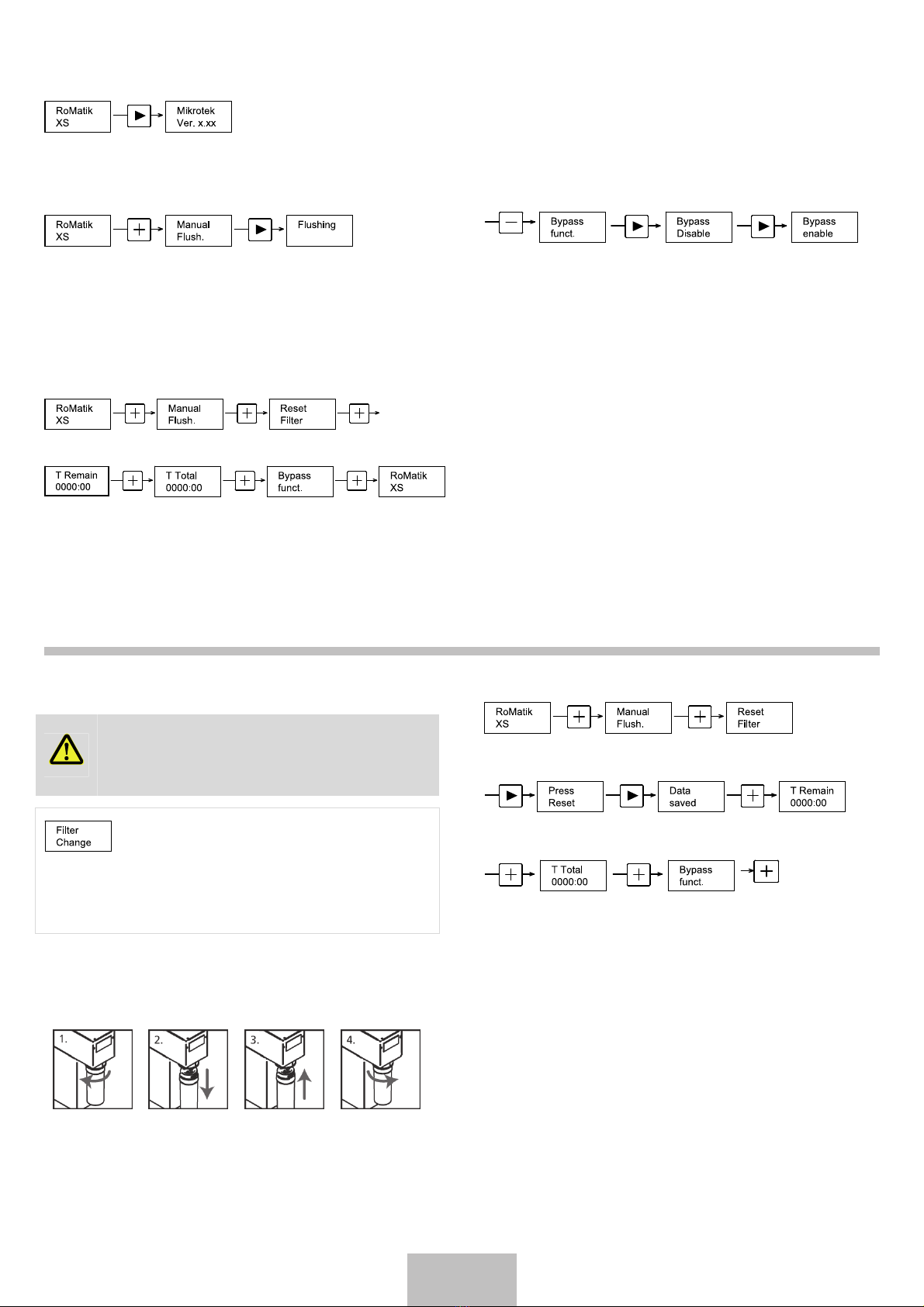

4.1 Operating panel

(1) Display

(2) Entry key

(3) Keys for navigation within the

menus

(4)

(5) On/off key

5 Operation

Switching on the device

Press the

button

The device is automatically in stand-by mode, if the connected warewasher does not

require any water.

5.1 Normal operation (water treatment)

As soon as the connected warewasher requests water, the device treats water.

Displaying the conductivity of the treated water

Keep the

button

pressed.

The conductivity of the treated water in µS/cm appears in the display.

5

English

Translation of the original operating instructions

Subject to technical alterations

89013023-05/2013-09