9

Important: The pumps must not be put into

operation, or even tested, unless the system is

filled with water.

Make sure that the storage tank is filled with a

sufficient quantity of water. The submersible

pump should be completely immersed in wa-

ter and the float switch must be floating.

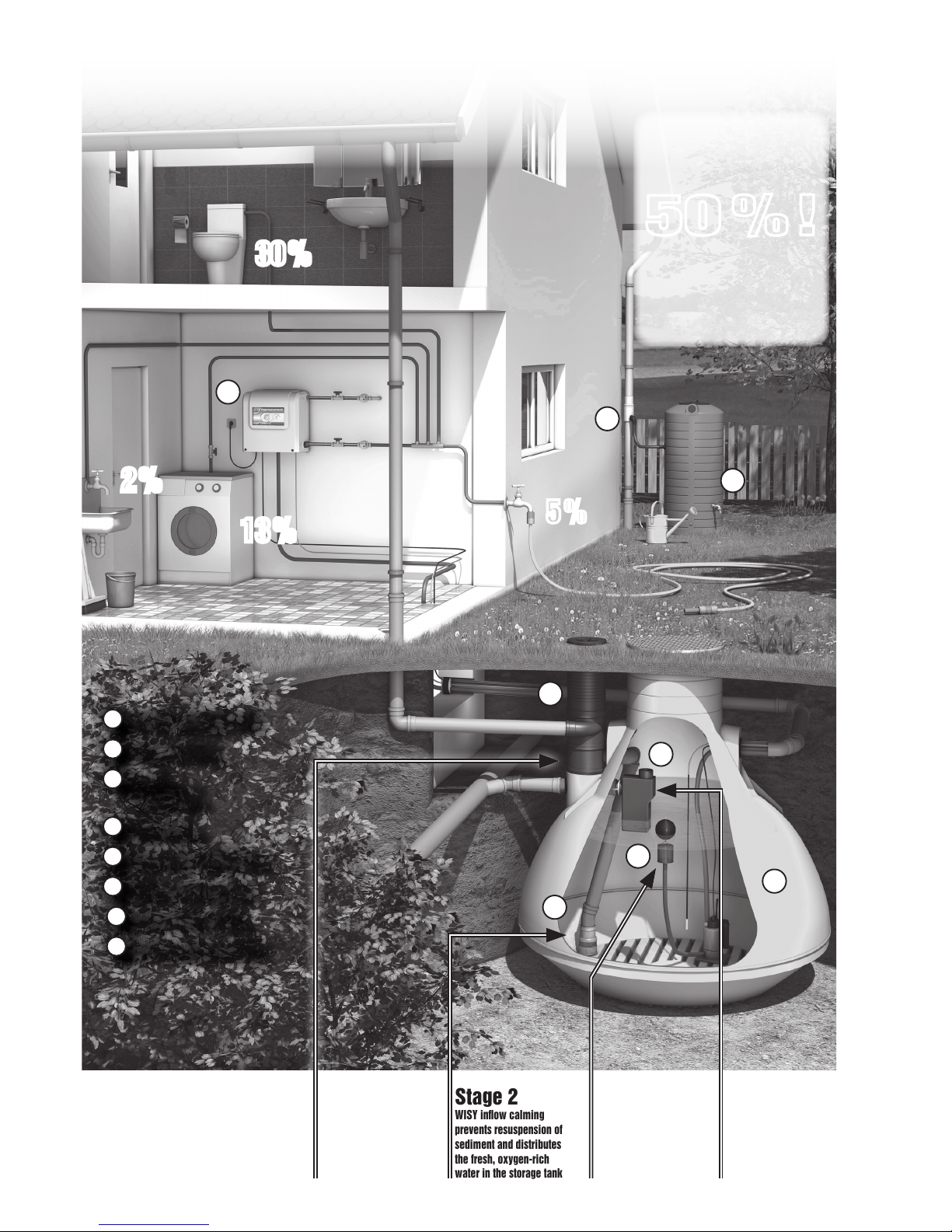

Basic operating principle

with two pressure pumps

Top-up with mains water

Commissioning

1. Venting and filling of the pump integrated in the wall unit by the loading pump:

Undo the venting/filling screw plug on the pump integrated in the wall unit;

connect only the loading pump to the electrical supply and wait until water

starts to escape from the screw plug; close the screw plug; pull out the elec-

trical plug for the loading pump and connect to the wall unit (blue socket on

underside of the wall unit).

2. Open the valves at the appliances.

3. Connect the OPTIMA to the electricity supply.

4. As soon as system has been bled, close the valves at the appliances! The

OPTIMA unit is ready to operate as soon as the maximum system pressure

is reached.

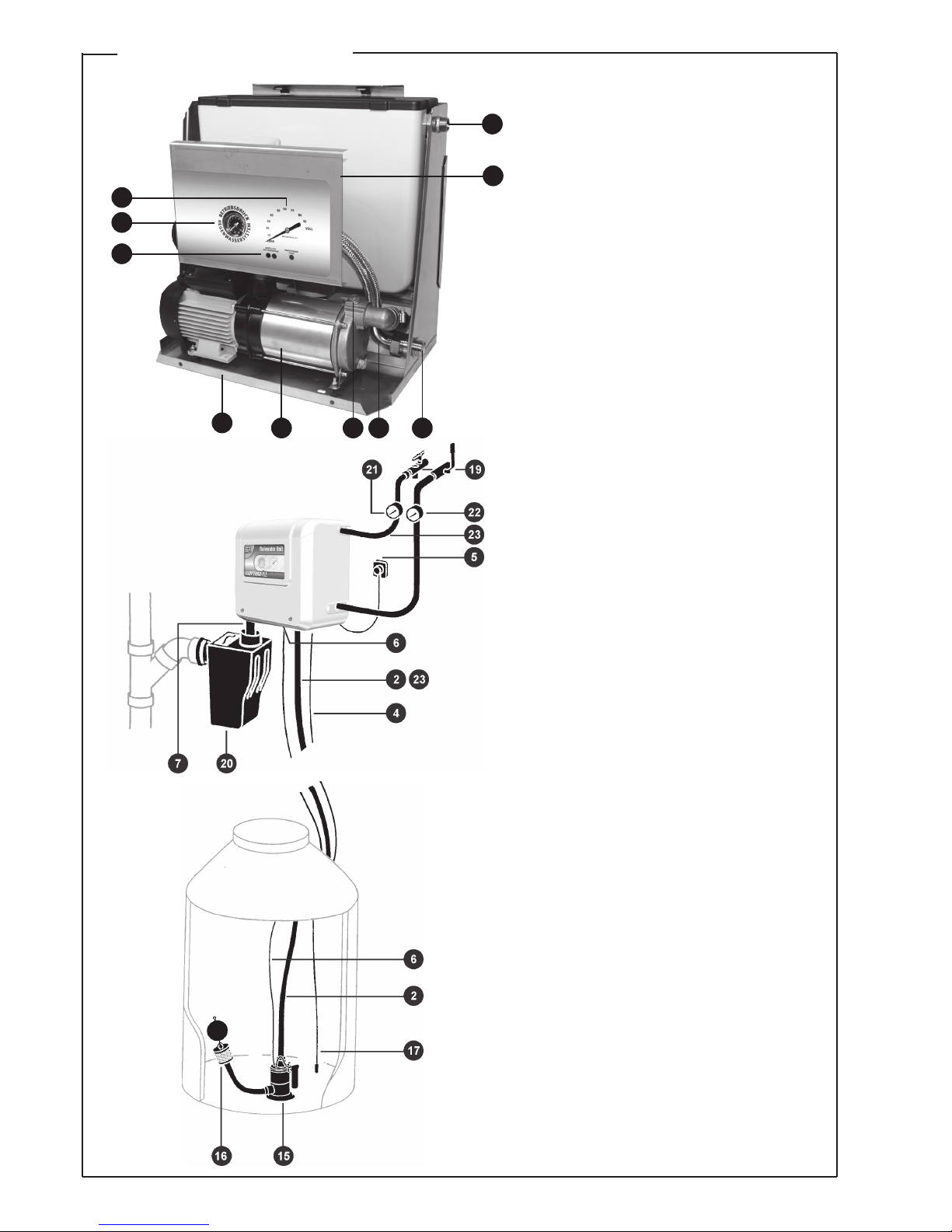

Design and operating principle

The innovative technology of the OPTIMA is based on a hydro-mechanical con-

trol concept which combines „traditional“ control by automatic switches with

the utilization of mechanical flow effects, but without the use of any additional

electronic control components.

The OPTIMA system developed by WISY essentially operates with two pressure

pumps: The submersible pump (or „loading pump“) of the OPTIMA system is

installed in the storage tank. It is equipped with a fine suction filter and a float

switch.

The loading pump pumps the rainwater to the normal-suction, multi-stage cen-

trifugal pump in the wall unit. As a result of the admission pressure, the cen-

trifugal pump is required only to pump and the mains water top-up inlet pipe

remains closed.

If a valve at one appliance (e.g. toilet flushing system) is opened, the pressure in

the circuit drops. When the factory-set pump starting pressure (1.5 bar) on the

automatic switch is reached, both pumps of the rainwater unit start up. When

the valves at all appliances are closed again, the pump control system (automa-

tic switch) turns off both pumps when the operating pressure is reached.

Note: If a „drip irrigation“ system (often computer-controlled) is to be connected

as an appliance to the OPTIMA, a small expansion vessel (around 15 l capacity)

must be installed downstream of the wall unit in the rainwater circuit. The expan-

sion vessel used for this purpose must be of the „flow-through“ type.

Switchover to mains water top-up is fully automatic. If the storage tank is empty,

the flow switch turns off the loading pump. Since the admission pressure then

drops to zero, mains water is automatically sucked out of the top-up tank of the

OPTIMA system. The water level in the top-up tank then falls, causing the float

valve for the mains water inlet to open so that mains water can be supplied to

the centrifugal pump.

If it is necessary to temporarily operate the OPTIMA system exclusively in mains

water operation (e.g. to carry out maintenance on the storage tank), then the

loading pump need only be electrically disconnected from the wall unit (remove

plug from socket on OPTIMA unit!).

The mains water top-up system is implemented as an open outlet in accordance

with DIN EN 1717 (formerly DIN 1988/4). Furthermore, a continuous exchange of

water takes place automatically in the mains top-up tank.

The tank can be topped up with approximately 95 litres of mains water per minu-

te if required. The mains water top-up tank has a storage capacity of 9 litres and

is also fitted with an emergency overflow (DN 70) as an additional precaution.

Every time the OPTIMA system starts up, a measurement of the tank fill level

is triggered. The clock dial indicates the level in %. When the measurement is

complete, the needle gradually drops back to the 0 position again.

A pressure gauge in the sight glass of the OPTIMA indicates the relevant system

pressure at which the rainwater unit is currently operating.

When the system is completely empty of water, the dry run protection system

integrated in the automatic switch shuts down both pumps.

Shutdown of loading pump

Water exchange in the mains water

top-up tank

Operating pressure indicator

Integrated dry run protection