ESG-25U Progressive Type Safety Gear

Operating Instruction

Subject to change without notice! © Copyright WITTUR 2016

Sheet PM.7.005160.EN.04

Version -

Date 30.08.2019

Approved WAT/KKR

1. General information prior to installation

1.1 Description and functions

ESG-25U is an unidirectional progressive type safety

gear with mechanical and electrical components.

Mechanical components are consisting of a

combination of disk springs, braking elements and

trigger mechanism with movable roller. The safety gear

is activated by a compression spring. The electrical

components (magnets) are used to keep the safety gear

in initial position. In normal run operation the magnets

are powered to keep the activation spring compressed.

The main function of the safety gear is to safely stop

the elevator car in down-direction (acc. EN 81-20/50)

if the car speed exceeds predened nominal speed

irrespective what the reason for the increase in speed

may be. The device is adjusted (according to load and rail

conditions) and sealed in the factory. Later adjustments

will not be necessary and are in any case prohibited for

safety reasons. For installation always a pair of safety

gears is used.

1.1.1 Safety gear activation

If the car speed exceeds predened nominal speed

the activation of the safety gear is carried out by an

external speed control unit (see chapter 4.5), which is

cutting the power supply on magnets. This causes the

preloaded activation springs to expand and leads to

an engagement of the rollers. The elevator car will be

brought to a standstill holding tight at guide rails.

The speed control unit has to be a CE certied device(SIL

3 according EN 81-20 PESSRAL) or an alternative device

with the same high(or higher) security level. In case

of an alternative device, total safety system has to be

assessed.

1.1.2 Safety gear reset

To release the engaged safety gear, at rst emergency

rescue switch has to be switched on and power has to be

supplied to the magnets (reset speed control unit). The

elevator car has to be moved out of gripping in upward

direction with powered magnet. This process resets the

trigger mechanism in its initial position.

After switching off emergency rescue the reset process

is completed.

If safety gear is activated but not engaged (e.g.

power loss at standstill) an additional step has

to be carried out to reset the safety.

After emergency rescue switch activation and speed

control unit reset, the car has to be moved down with

recall drive until it is stopped by the safeties (rollers

engaged). In the following step the car is moved out of

gripping like mentioned above.

For elevators with safety gear mounted on the top of

the frame it is recommended to activate and program

parking position for an accessible landing. It has to

be ensured, that car roof is accessible in this parking

position.

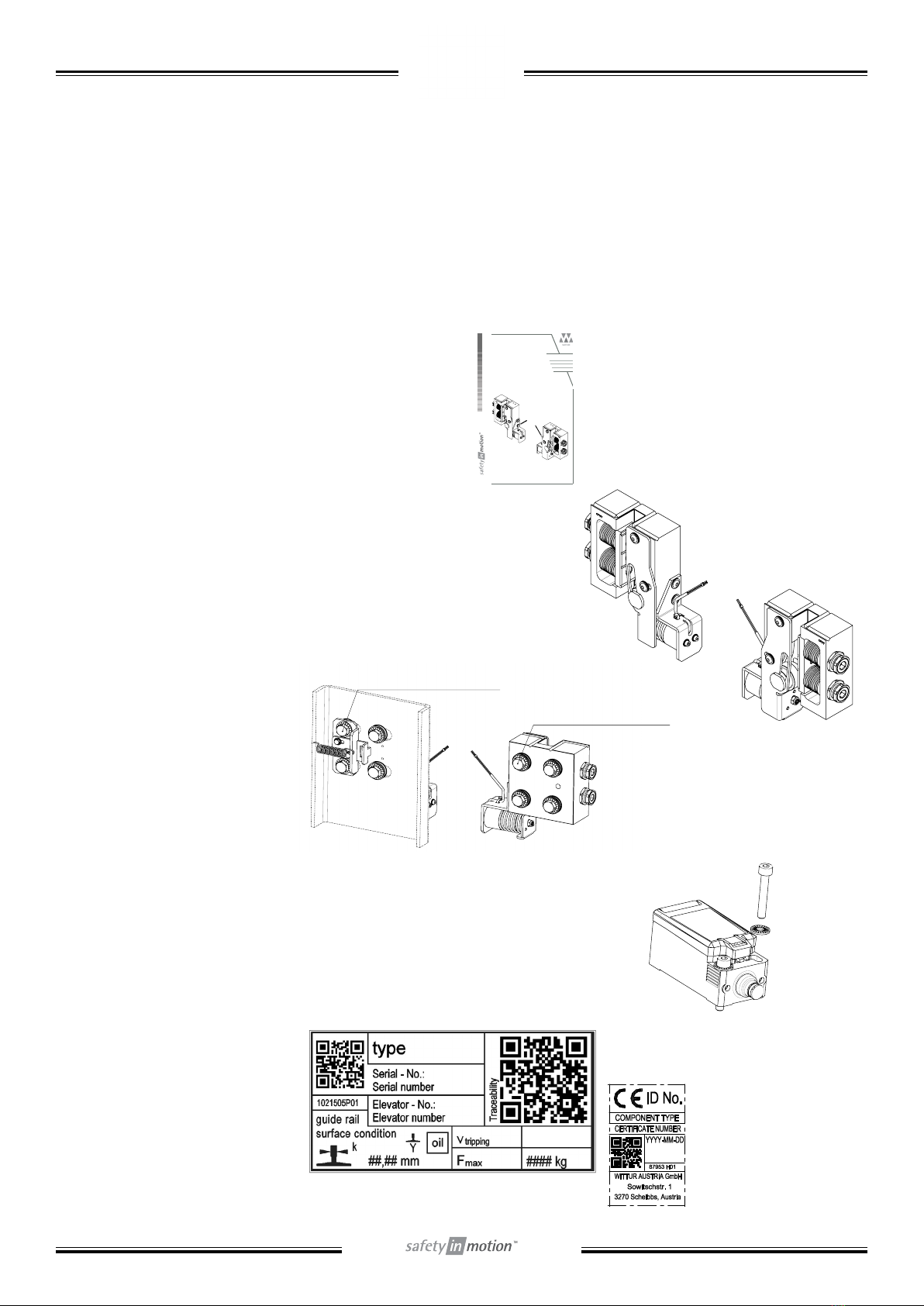

1. Brake lining

2. Safety gear block

3. Seal (sealing wax)

4. Adjustment screw

5. Disk spring assembly

6. Roller

7. Trigger mechanism

8. Magnet unit

1

2

3

4

5

6

7

8

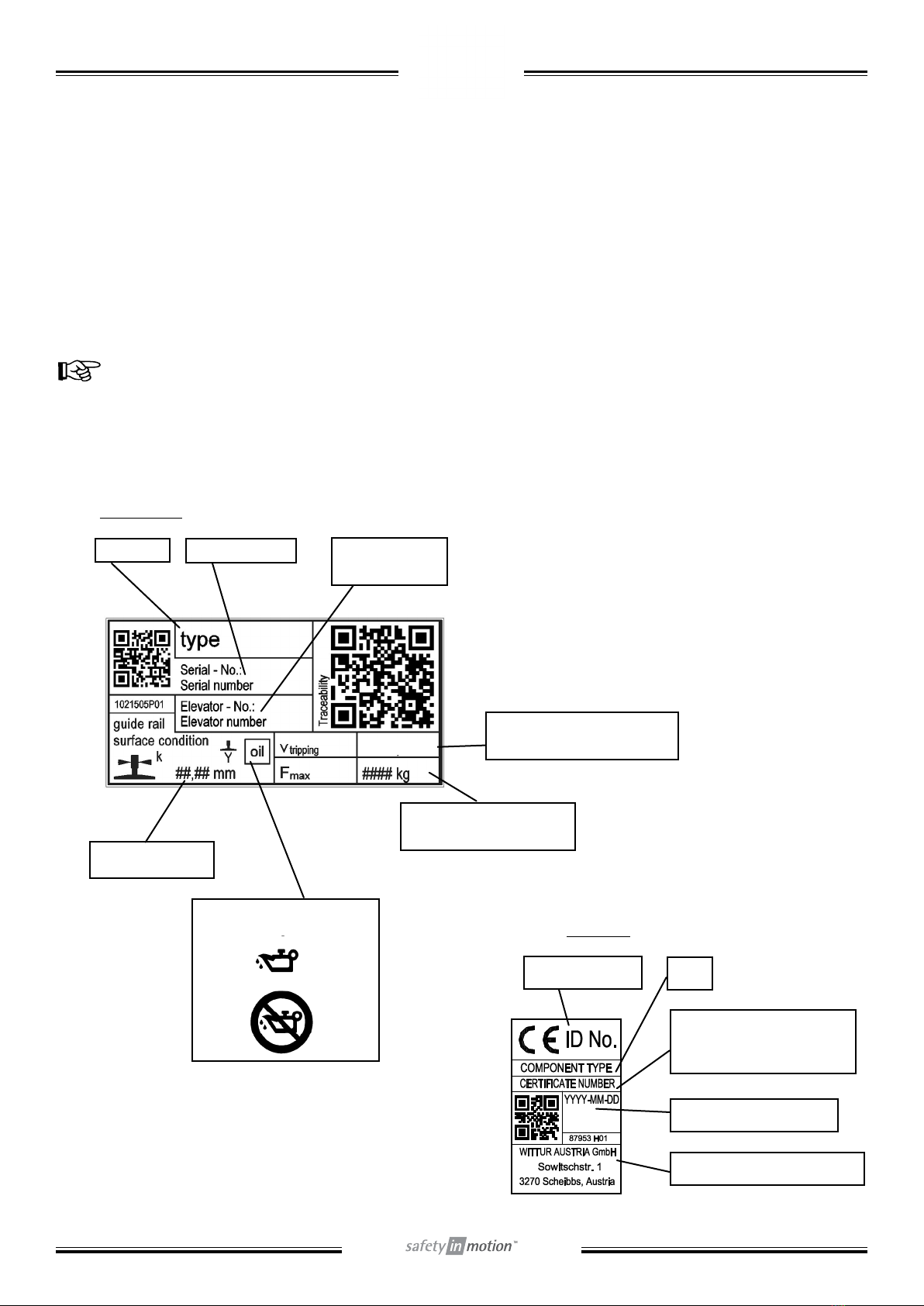

1

2

+

0,50

0

4

±2

A2

1:1

SCALE

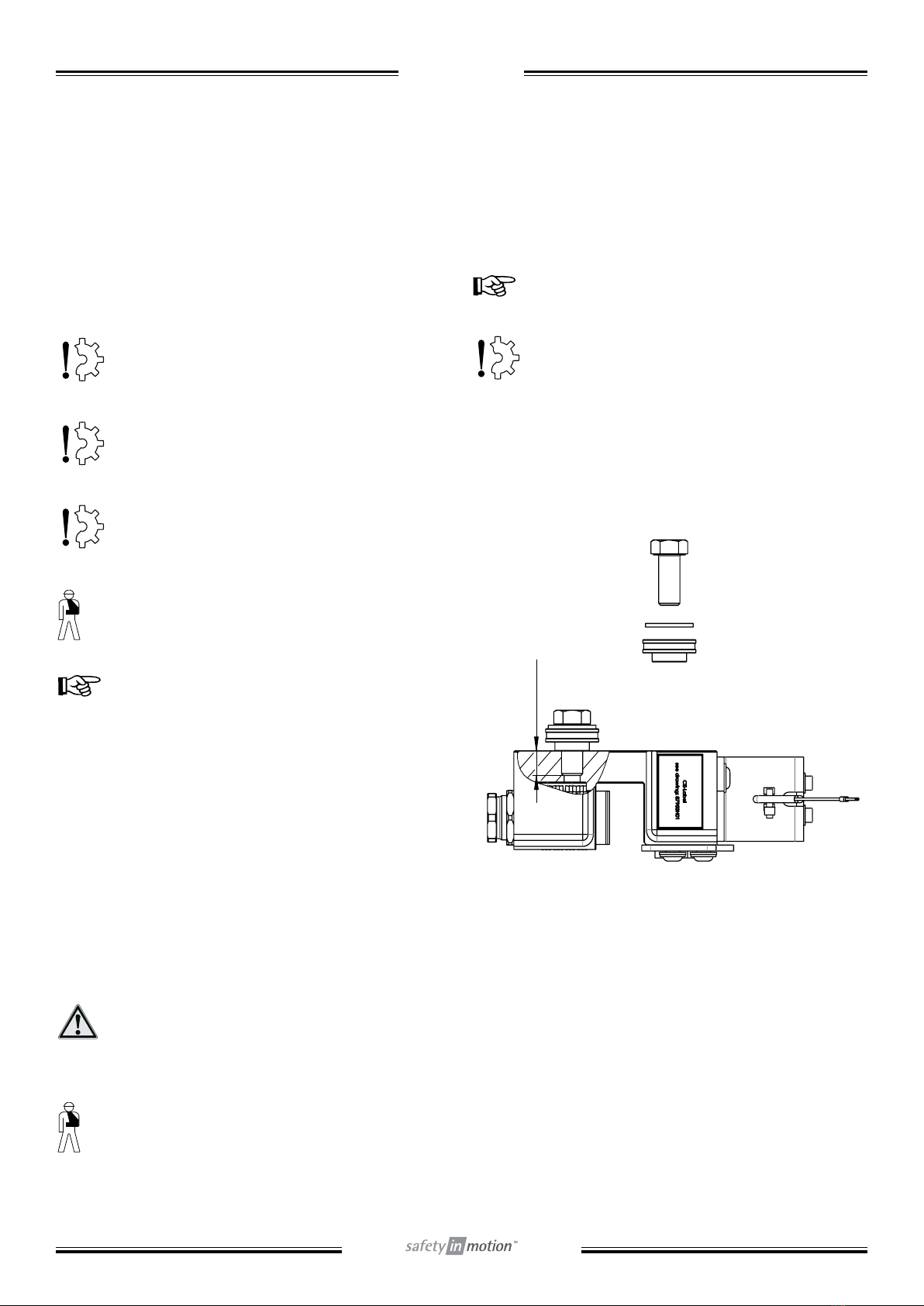

PRODUCT CODE

ESG

PRODUCT CATEGORY

7 - SAFETIES

ADD. DESCRIPTION

Safety gear

DESCRIPTION

1019552

DRAWING NUMBER

ESG-25U

GEOM. TOLERANCE SYMBOLS

ISO1101

A

FUNCTIONAL CLASS

GT2

GEN. TOLERANCE WST-00033

ISO1302

AT1DujaZ

DATE

1/1

DESIGNED BY

SHEET

REVISION

FIRST APPROVAL

DATE

DRAWN BY

©WITTUR HOLDING GmbH

A

B

C

D

E

F

12345678

The reproduction, distribution and utilization of this document as well as the communication of its contents to others without express authorization

is prohibited. Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model or design.

V5.0

Revision Qty.

Description

Done by

Approved by

Date of issue

9 10 11 12

G

H

SURFACE TEXTURE SYMBOLS

SIZE

Change no.