Contents Page

1 General information prior to installation

1.1 Description and functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.2 Liability and guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.3 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.4 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.5 Advice for when working on safety components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.6 Content of supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.6.1 Safety gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.6.2 Safety gear with housing and separate synchronization . . . . . . . . . . . . . . . . . . . . . . .5

1.6.3 Safety gear with housing and integrated synchronization . . . . . . . . . . . . . . . . . . . . . .6

2 ame plate, designation, identification

2.1 Labelling according to EN81 (CE) and B7588 (China) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.2 Labelling according to ASME A17.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.3 Labelling according to Notification No. 2010-0009 (Korea) . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3 Installation and adjustment

3.1 ripping wedge synchronization and adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.2 Alignment of safety gear housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.3 Assembling and adjustment of housing and synchronization . . . . . . . . . . . . . . . . . . . . . . . . .13

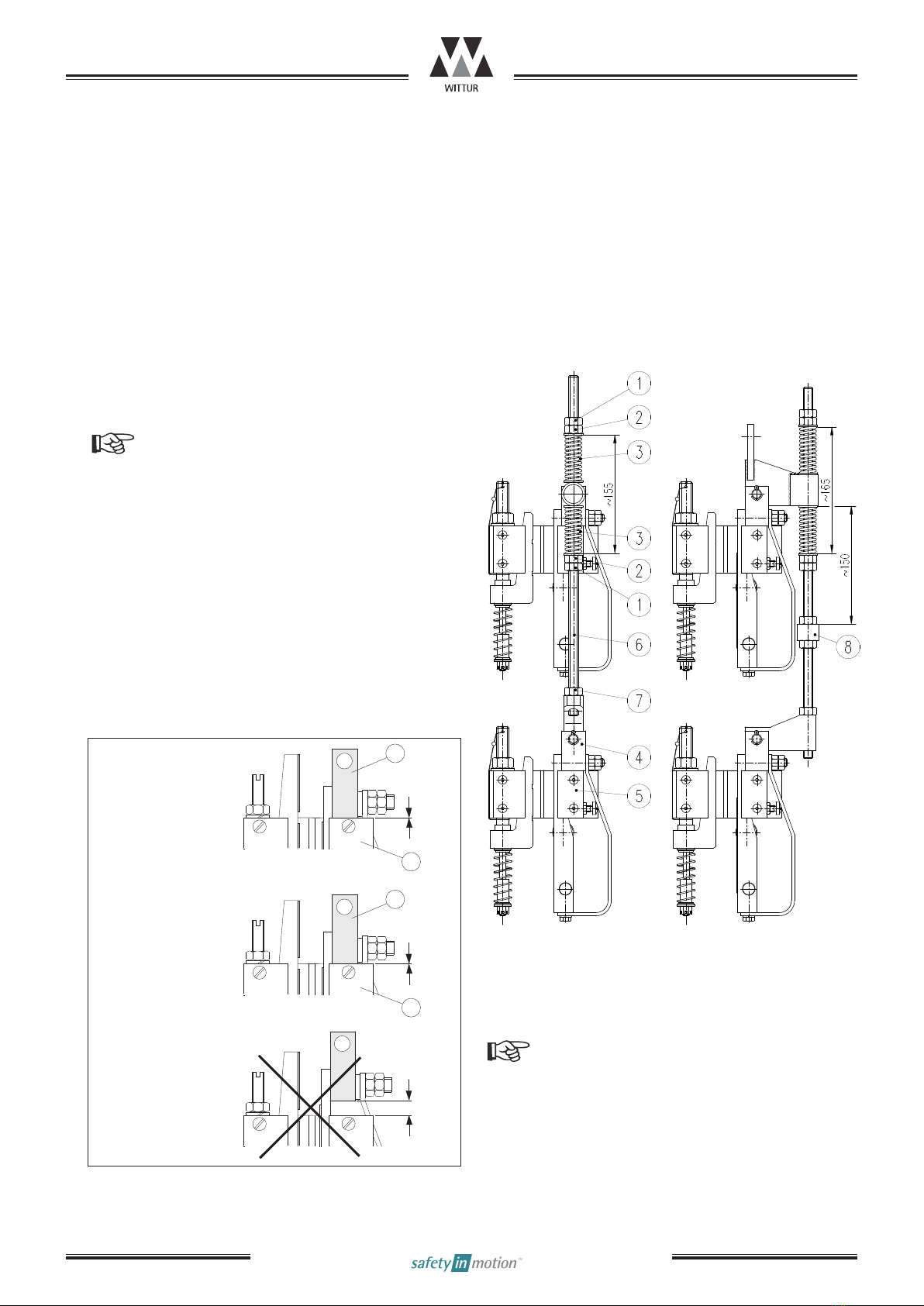

3.3.1 Safety gear with housing and separate synchronization . . . . . . . . . . . . . . . . . . . . . . .13

3.3.2 Safety gear with housing and integrated synchronization . . . . . . . . . . . . . . . . . . . . . .15

3.4 Electrical installation of the safety gear contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3.4.1 Safety gear contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4 Function testing

4.1 Static functions test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.2 Dynamic functions test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.2.1 ripping test for car safety gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.2.2 ripping test for counterweight safety gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.2.3 Required check after gripping tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.2.4 Visual checks after a safety gear test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.3 ripping distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.3.1 Measuring of gripping distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.3.2 Check of gripping distance “s” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

5 Maintenance, inspection and repair

5.1 Maintenance and inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

5.1.1 eneral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.1.2 Maintenance and inspection check list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.1.3 Cleaning of guide rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.2 Returning tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.3 Operational life time of the safety gears . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.4 Carrying out repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.5 Disposal of Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.6 Spare parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

5.6.1 Safety gear with housing and separate synchronization . . . . . . . . . . . . . . . . . . . . . . .27

5.6.2 Safety gear with housing and integrated synchronization . . . . . . . . . . . . . . . . . . . . . .28

A EX A

Progressive Type Safety Gear

SGB03 - Duplex

Operating instructions

Blatt/

sheet

D7A5M B.001

Datum/

date

16.03.2002

Stand/

version

E-07.08.2020

eprüft/

approved

WAT/KKR

Änderungen vorbehalten! Subject to change without notice!

E

E

E

E

E