Gas Range (GR) Series

Gas Range (GR) Series

Installation Information

2-2

#822634 - Revision A - January, 2013

INSTALLATION INFORMATION

NEVER USE OPEN FLAMES TO CHECK FOR GAS

LEAKS. ONLY USE A COMMERCIAL LEAK DETEC-

TION SOLUTION OR SOAP SUDS AROUND GAS

CONNECTIONS TO CHECK FOR LEAKS. DO NOT

USE LIQUID NEAR VALVE STEMS.

Gas Supply

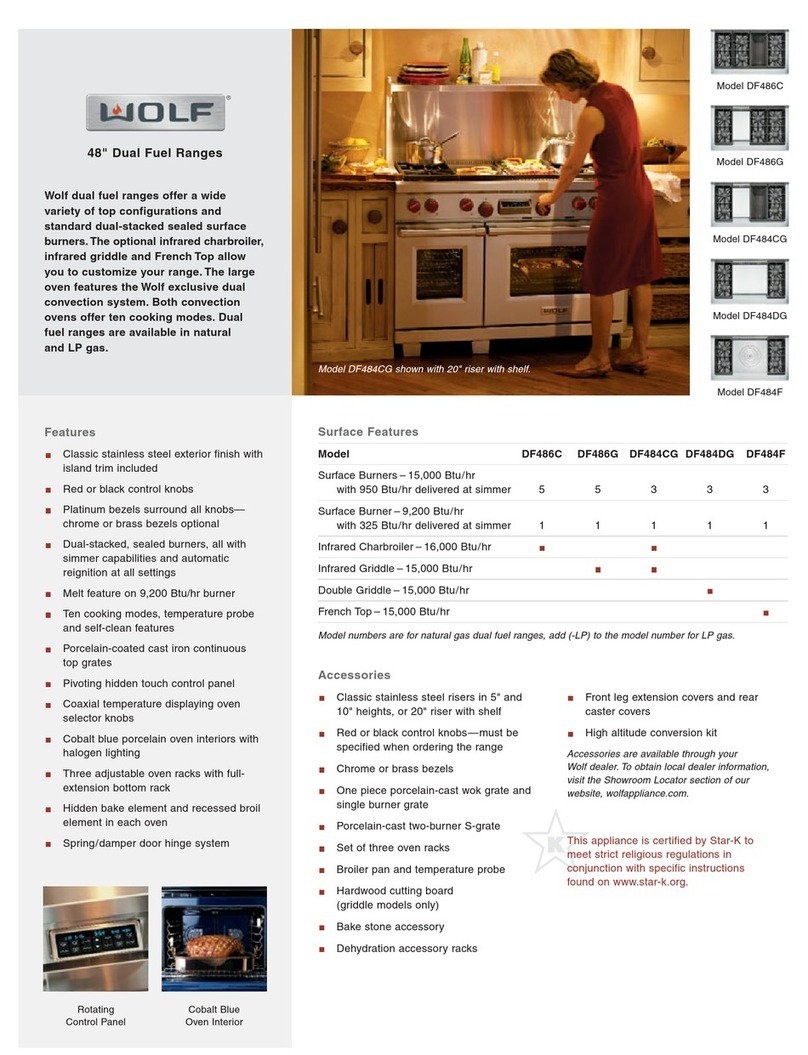

Installation must conform with local codes or, in the

absence of local codes, with the National Fuel Gas

Code.

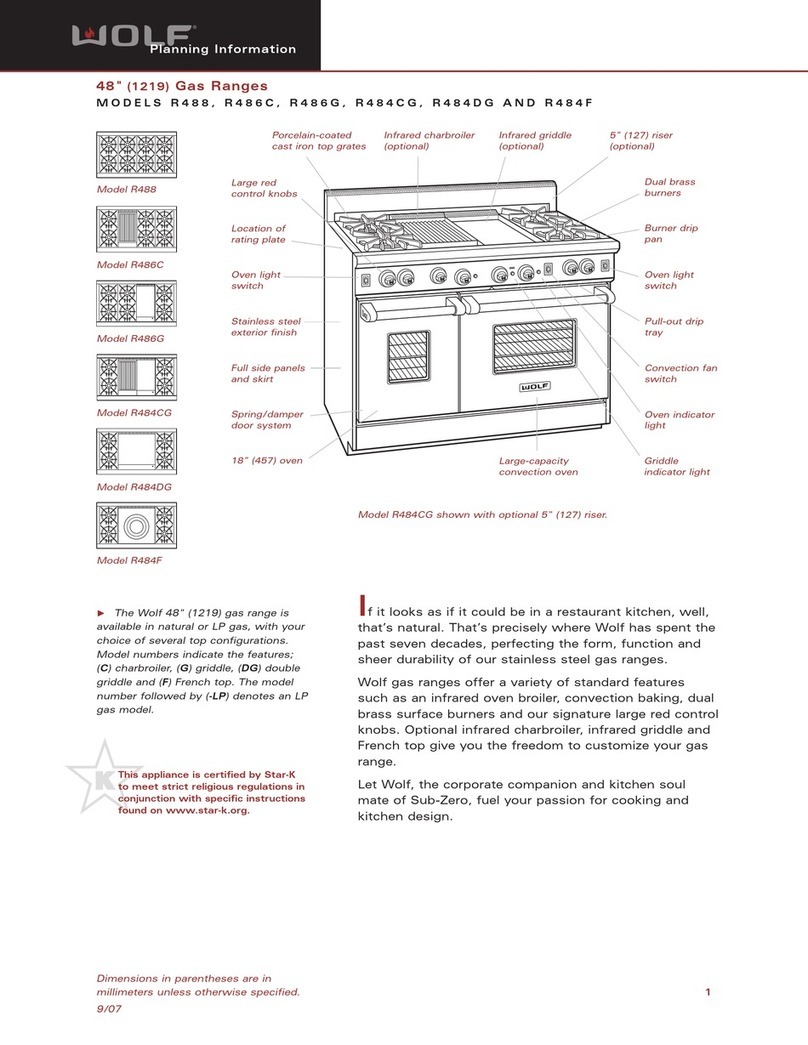

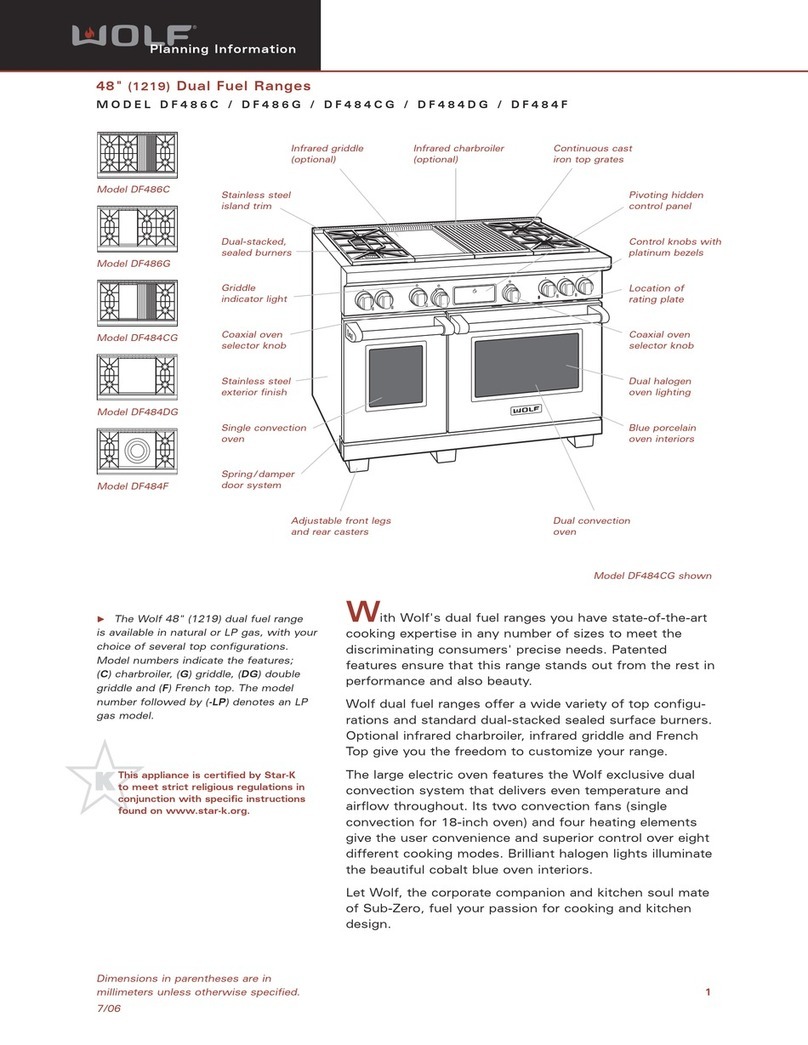

Locate the gas supply within the shaded area shown in

the illustration for your specific model on the following

pages. The range is equipped for use with natural or liq-

uid propane (LP) gas. It is design certified by the

Canadian Standards Association (CSA) for natural or

LP gases. The product rating plate has information on

the type of gas that should be used. If this information

does not agree with the type of gas available, check

with the local gas supplier.

The range must be connected to a regulated gas sup-

ply. The supply line must be equipped with an

approved external gas shut-off valve located near the

range in an accessible location. Do not block access to

the shut-off valve. (See Figure 2.1)

A gas supply line of 3/4" (19) rigid pipe must be provid-

ed to the range. If local codes permit, a certified, 3' (.9

m) long, 1/2" (13) or 3/4" (19) ID flexible metal appli-

ance connector is recommended to connect the range

to the gas supply line. For LP gas, piping or tubing size

can be 1/2" (13) minimum. LP gas suppliers usually

determine the size and materials used on the system.

The pipe coming out the back of the range has 1/2"

(13) male threads. Pipe joint compounds, suitable for

use with natural or LP gas should be used.

Wolf LP gas ranges will function up to an altitude of

10,250' (3124 m) without adjustment; natural gas

ranges will function up to an altitude of 8,600' (2621 m)

without adjustment. If the installation exceeds this ele-

vation, contact an authorized Wolf dealer for a high alti-

tude conversion kit.

Leak Testing

Use a brush and liquid detergent to test all gas connec-

tions for leaks. Bubbles around connections will indi-

cate a leak. If a leak appears, shut off the gas valve

and adjust connections. Then check connections

again. Clean all the detergent solution from the range.

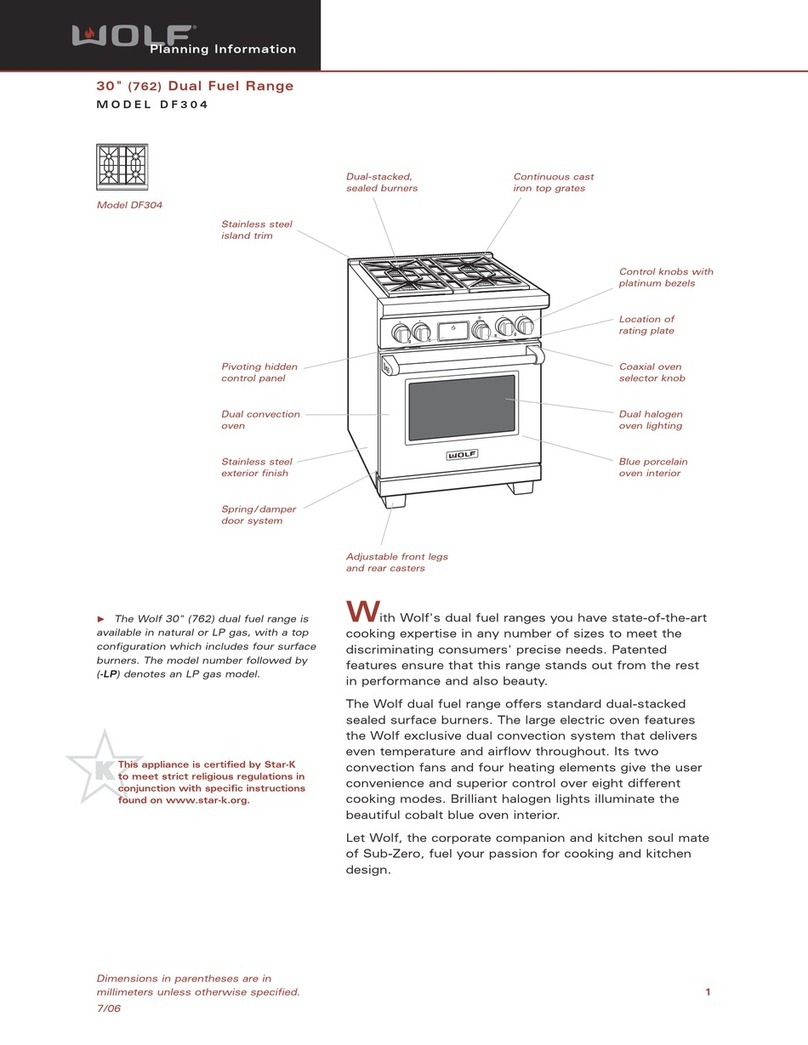

This section of the manual covers some of the installation issues that a service technician may need to know when

servicing a gas range. If additional installation information is needed after reviewing this section of the manual,

please refer to the installation guide or contact the Wolf Appliance Customer Service Department.

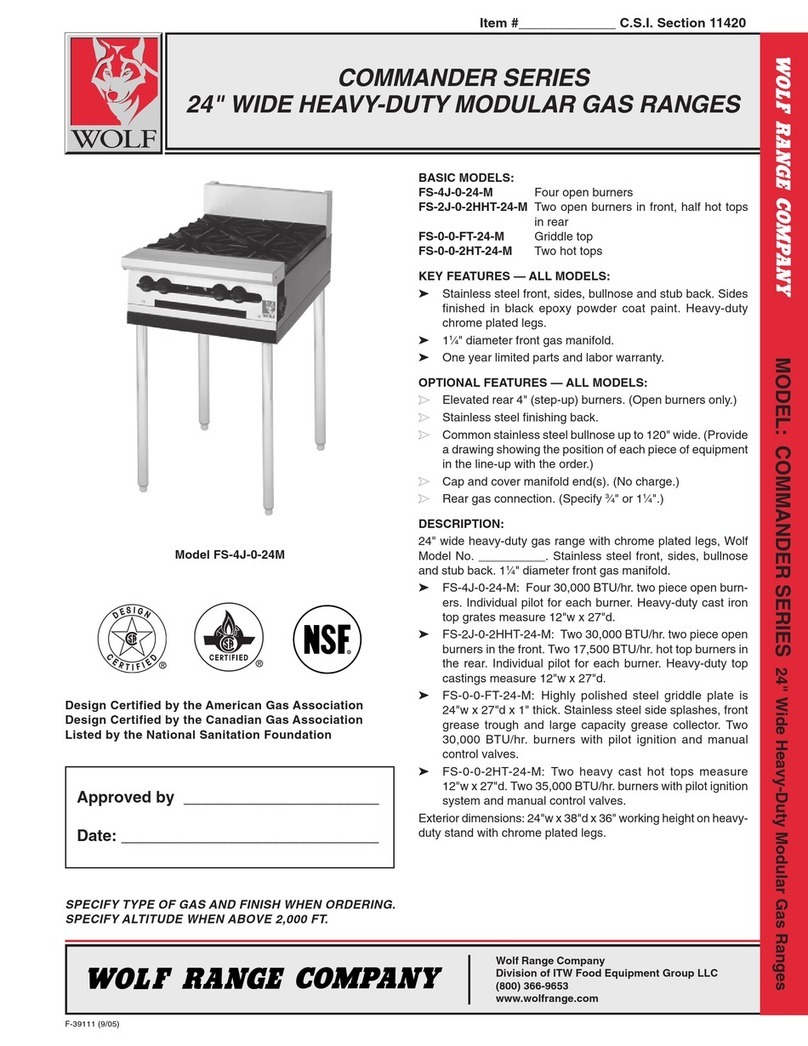

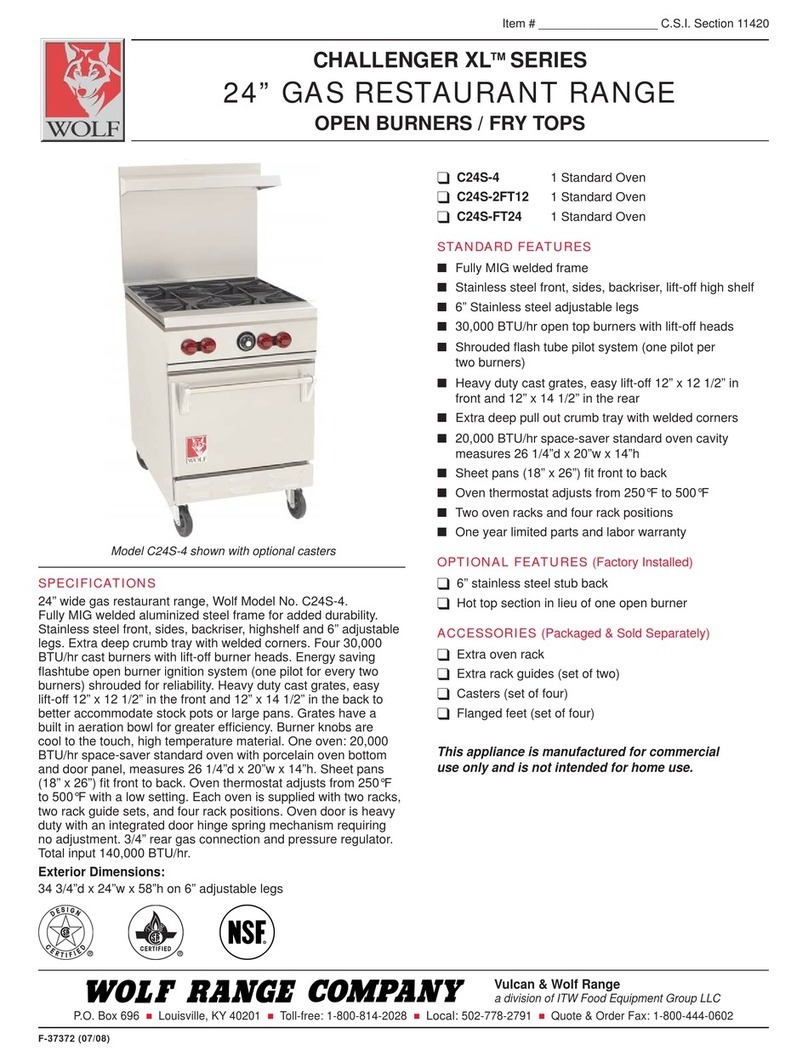

Gas Supply Requirements

Natural Gas

Gas Supply Pressure 5" (12.5 mb) WC

Min Line Pressure 7" (17.5 mb) WC

Max Pressure to Regulator 14" (34.9 mb) WC,

.5 psi (3.5 kPa)

LP Gas

Gas Supply Pressure 10" (25 mb) WC

Min Line Pressure 11" (27.4 mb) WC

Max Pressure to Regulator 14" (34.9 mb) WC,

.5 psi (3.5 kPa)