Einscheibenschleifmaschine FLAMENCO, #053365

6.2 Description of grinding, milling and cleaning discs

Paper grinding discs double sided, 375 x 40mm

Grade 16, #013531, Grinding of subfloors

Grade 24, #013527, Preparing and grinding of dirty screeds

Grade 40, #013528, Grinding and levelling smoothing compounds

Grade 60, #013529, Finish-grinding of smoothing compounds

Grade 80, #013530, Grinding and abrading timber surfaces

Grinding gauze double sided, 400mm

Grade 60, #013548, Grinding of parquet varnish, coatings and old surfaces

Grade 80, #013331, Fine-grinding of surfaces

Grade 100, #013332, Fine-grinding of surfaces

Grade 120, #013333, Fine-grinding of surfaces

Grade 180, #013549, Fine-grinding of surfaces,

grinding/polishing of parquet + cork

Carbide grinding disc

Dismounting action much more aggressive compared to paper disc. High grinding efficiency. High tool life

(10 times higher as paper grinding discs).

Disc does not clog, due to open grains. Disc can be cleaned. Silicone or wax-spray can be used additionally

to reduce adhesion.

Grade 16, #013510, Abrading of anhydrite-screed, removing of dirt and adhesive residues

Grade 24, #013517, For abrading and rough grinding

Cylindrical brush disc, #015735

For preparing new anhydrite- and magnesia-screeds.

For abrading of anhydrite- screed, for abrading areas contaminated with paint, mortar, felt-, foam- and

adhesive residues.

Corrugated steel-brush disc, #013539

For brushing and preparation of subfloors. For removing the loose sintered material on new anhydrite- and

magnesia screed.

Flat steel brush disc #015738

For removal of foam, felt and hessian backing residues. For abrading anhydrite and self-levelling screeds, for

industrial cleaning. Brush length 45 mm. The open brushes work well with tacky residues. The brushes do not

clog.

Grinding disc with 6 stones K20 #013540

For grinding uneven areas of screed and levelling compounds, paint or gypsum residues. Sharp edges give

high efficiency.

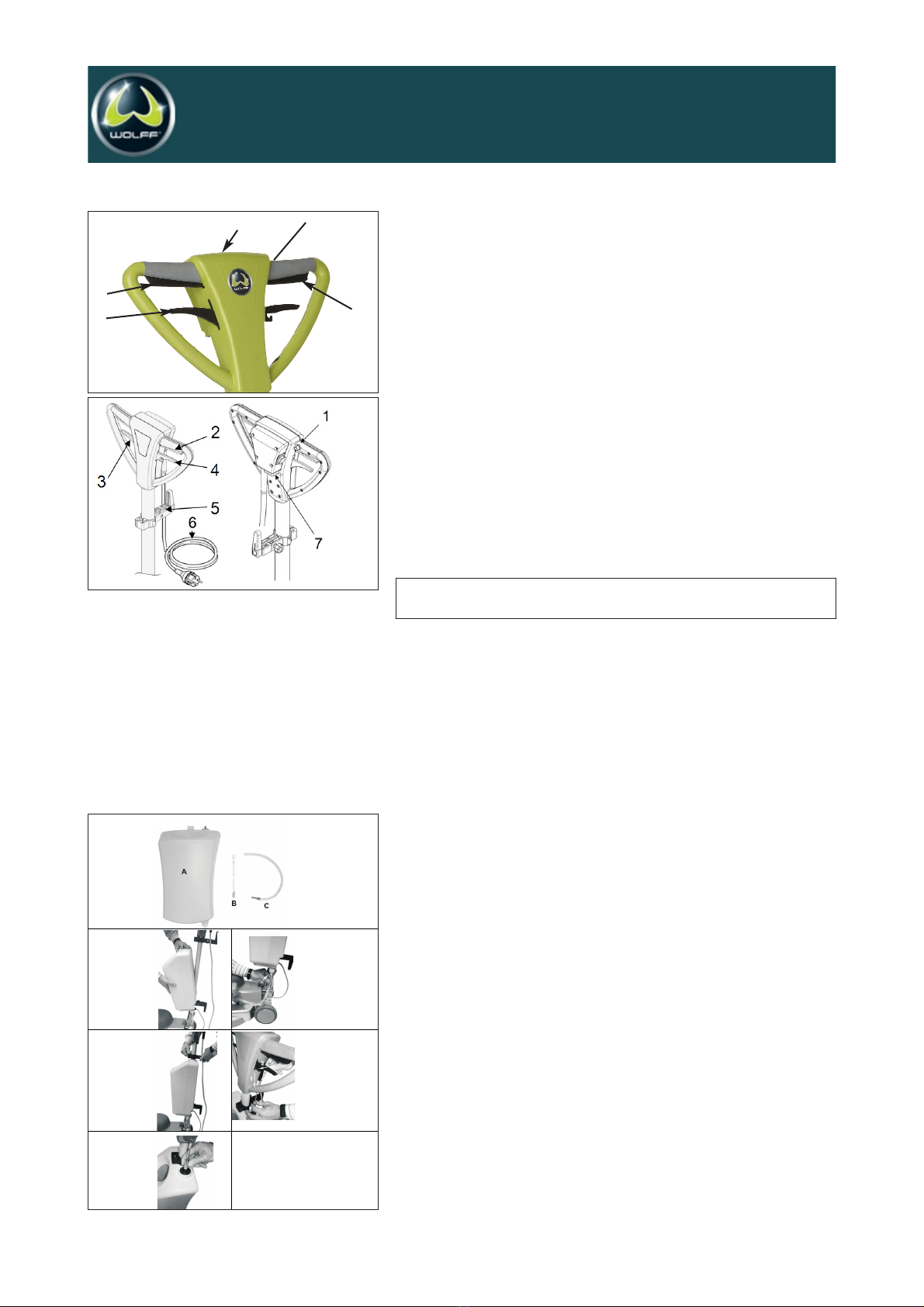

System-milling-disc

The system milling disc can be equipped with different interchangeable milling modules. The system-discs

are available complete, or, as single modules

Use:

System carbide milling disc,

#013569: for removing thick adhesive residues and fibre-, felt- and foam residues (scraping action)

System diamond milling disc, #020943

for grinding extremely hard smoothing compounds and industrial floors, as well as epoxy- and polyester coatings

16