9

An ongoing program of product improvement may require us to change

specifications without notice. (-W). Revised September 2009

Wood Stone Corporation

1801 W. Bakerview Rd.

Bellingham, WA 98226 USA

Toll Free (800) 988-8103

Tel (360) 650-1111

Fax (360) 650-1166

Mountain Series Installation and Operation Manual

oVen VentinG

Install venting system in accordance with the duct manufacturer's instructions and in accordance with all local

codes. All field built components should be built to the applicable codes and standards and are subject to the

approval of the authority having jurisdiction.

The following are the manufacturer’s recommendations for venting the Wood Stone MS (Mountain Series) -W (wood-fired)

ovens. It is never appropriate to use “B vent” in any part of an exhaust system connected to a Wood Stone oven. All ducting

material must be manufactured to the specifications of a grease duct and a listed building heating appliance chimney. This

is a wood-fired oven and must be vented as a solid fuel piece of equipment. Due to the possibility of sparks entering the

system, exhaust systems serving solid fuel equipment must be vented separately from other non-solid fuel equipment.

Submit your venting plans to your local authorities before proceeding with your installation, as there may be additional

requirements in your area. The duct serving this solid fuel oven should be inspected at least twice a month during the

first two months of operation, to establish rate of creosote buildup and necessary cleaning schedule. If creosote or soot

has accumulated, it should be removed to reduce the risk of a flue fire.

1. Direct Connection:A listed building heating appliance chimney, also listed as a grease duct as described in NFPA

96, connected directly to the oven flue collar and provided with a power ventilator listed for restaurant appliance

exhaust. The power ventilator should be rated for a minimum of 450 degrees Fahrenheit (F). Wood Stone does

not recommend the use of an in-line fan. A field built grease duct, constructed and installed to the specifications

of a grease duct as detailed in NFPA 96 or the International Mechanical Code, may also be used.

A static pressure of -0.14 inches water column is necessary at the oven flue collar to ensure that flue gas

temperatures do not exceed 450 degrees F at the fan inlet. The CFM required to attain this static pressure will

depend on the configuration of your particular installation but will probably be between 500 and 700 CFM.

Wood Stone provides a port in the flue collar of the oven for insertion of a magnehelic gauge. This enables

the installer to monitor the draft to ensure proper operation of the venting system. This measurement may

also be taken by inserting the end of the probe through the oven doorway, upwards to the oven flue collar.

NOTE: Double door ovens (Models ending in DD), have two flue collars, both must be connected and a static

pressure of -0.14 inches must be maintained at each collar.

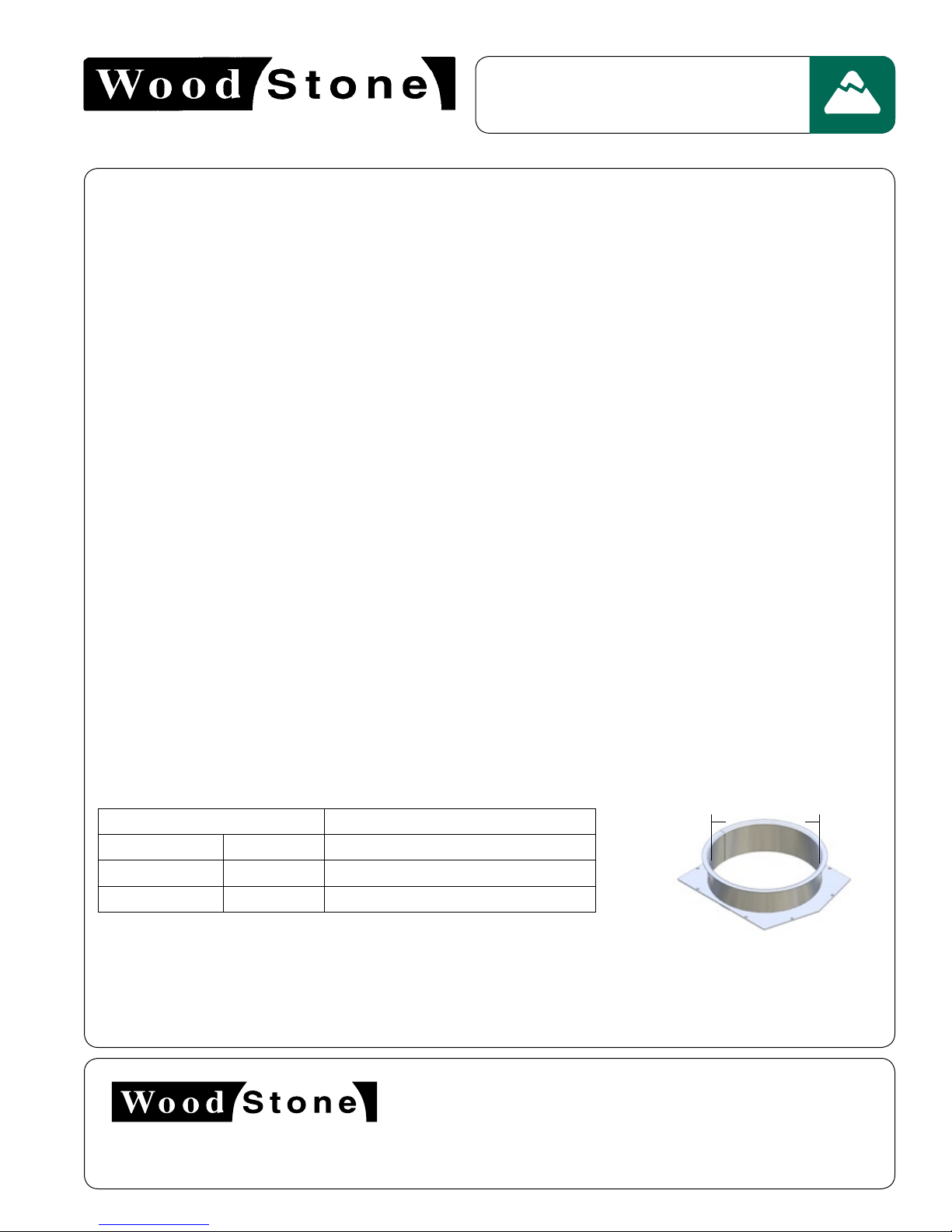

OVEN MODEL SERIES FLUE COLLAR I.D. (NOMINAL)

Mt. Adams WS-MS-5 10 inch

Mt. Baker WS-MS-6 10 inch

Mt. Rainier WS-MS-7 10 inch

NOTE: MS-4 ovens come standard with a round 8" O.D. collar and do not

require the flue adapter for a direct connection.

NOTE: If your MS-5, MS-6, or MS-7 oven is ordered from Wood Stone without a hood, it will have a round flue

adapter installed to facilitate direct connection to a round duct. If the oven is to be installed under a hood, it MAY

be necessary to remove the round adapter to properly position the hood. This is done by removing the screws

that attach the adapter to the oven. Please contact Wood Stone if you have any questions.

Collar I.D.

THERE ARE THREE OPTIONS:

THIS OVEN MUST BE VENTED AS A SOLID FUEL APPLIANCE

Flue Adapter