-4-

2. SAFETY PRECAUTIONS

2.1 SAFETY REGULATIONS

- Woodworking machine is high speed and high-risk equipment, so operator who is been suitably trained can use the

machine for safety production.

-The manufacturer disclaims all responsibilities for damages to persons or things, which might be caused by any failure

to comply with the safety regulations.

-The manufacturer disclaims all responsibilities for damages to persons or things, which might be caused by any failure

of electrical installation or nonstandard assembly.

- The manufacturer is not responsible for any damage deriving from arbitrary modifications made to the machine.

- It is prohibited to use the machine when under the influence of alcohol, drugs or medication.

- All the operators must be suitably trained for use, adjustment and operation of the machine.

- The operators must carefully read the manual paying particular attention to the warning and safety notes. Furthermore,

they must be informed on the dangers associated with use of the machine and the precautions to be taken, and must

be instructed to periodically inspect the guards and safety devices.

- Before changing the blade, debugging the trouble, carrying out adjustment, or cleaning work, disconnect the machine

from the electric power by setting the main switch to stop to make sure the machine will not being operated wrongly.

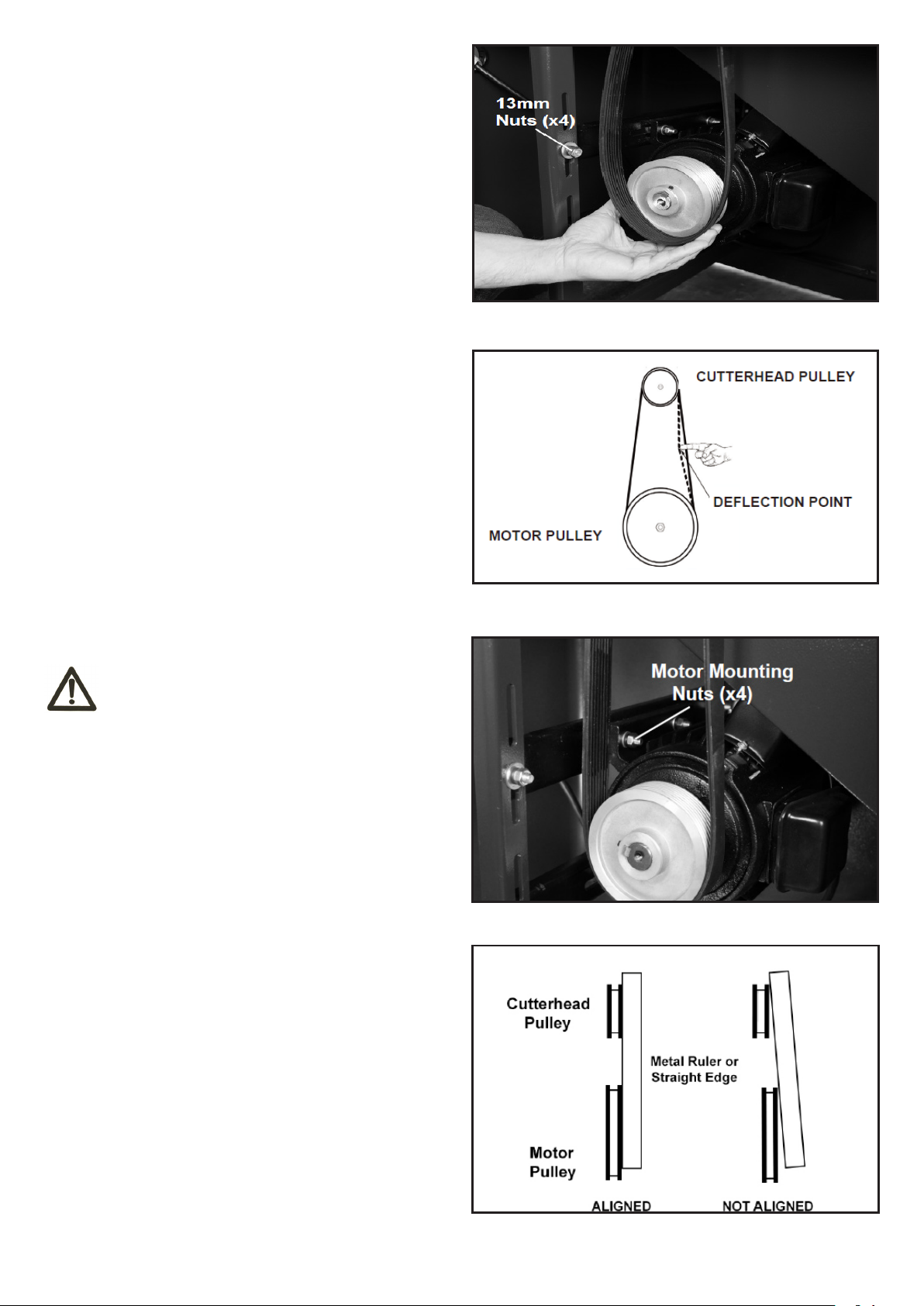

- After an initial bedding-in period or many hours of operation, the driving belts may slacken; this causes an increase in

the tool stopping time. Immediately tighten them.

- The working area around the machine must be kept always clean and clear, in order to have an immediate and easy

access to the switchboard.

- Never insert materials which are different from those which are prescribed for the machine utilization. The material to

be machined must not contain any metal parts.

- Never machine pieces which may be too small or too wide ithrespect to the machine capacity.

- Do not work wood which has evident defects (cracks, knots, metal parts, etc.)

- Never place hands among the moving parts and/or materials.

- Keep the tools tidy and far away from those not authorized persons.

- Never employ cracked nor uckled, neither not correctly reground tools. Nonstandard or blunt tools are forbidden,

either. Blade with broken edge or out of shape should not be used.

- Never use the tools beyond the speed limit recommended by the producers.

- Carefully clean the rest surfaces of tools and make sure that they find perfectly horizontally positioned, and with no

dents at all.

- Always wear gauntlets when handling the tools.

- Mount the tools in the right machining direction.

- Never start the machine before having correctly installed all the protections. The protection device should be installed

before starting the machine. The protection device should not be removed.

WARNING