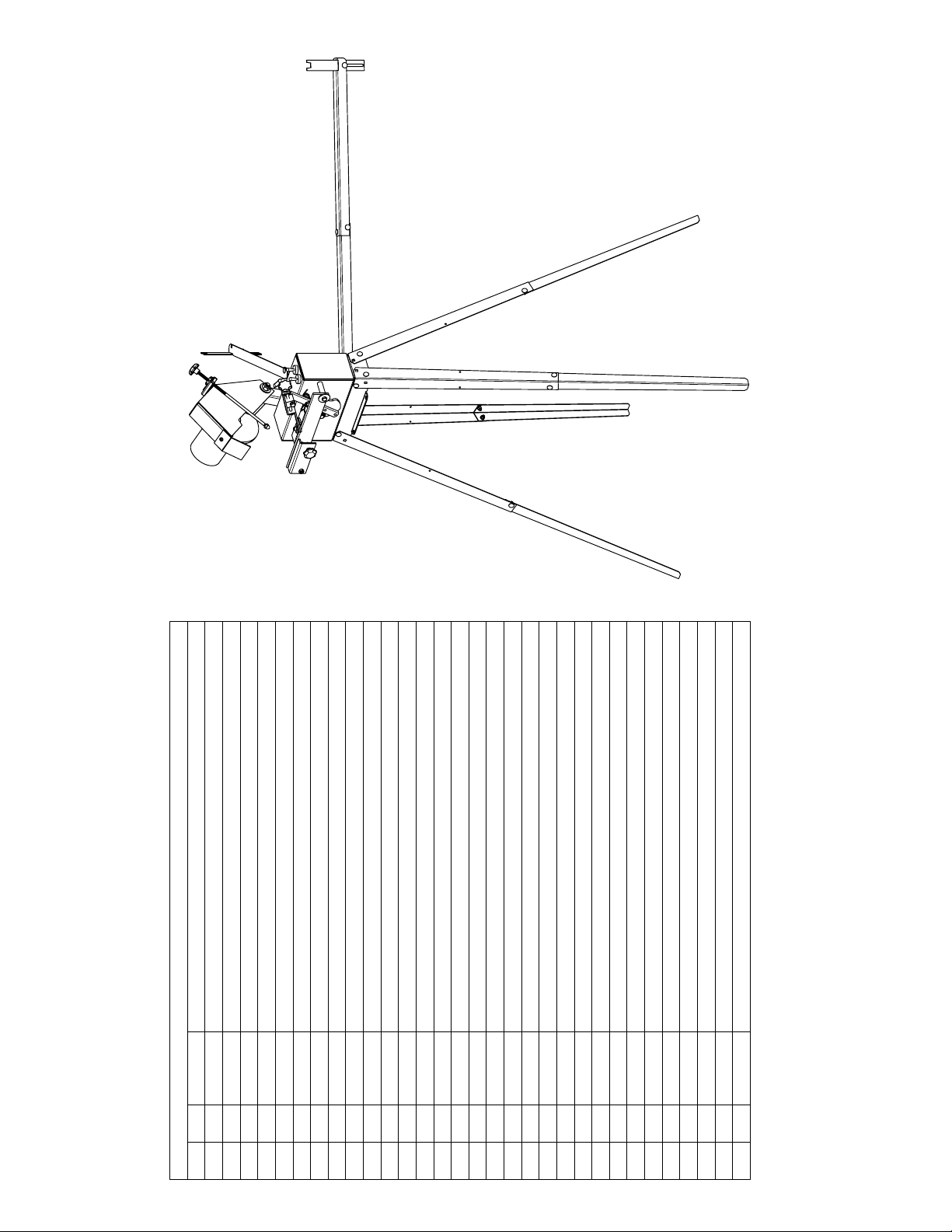

PARTS LIST

PARTS LIST

ITEM

QTY

PART NO

DESCRIPTION

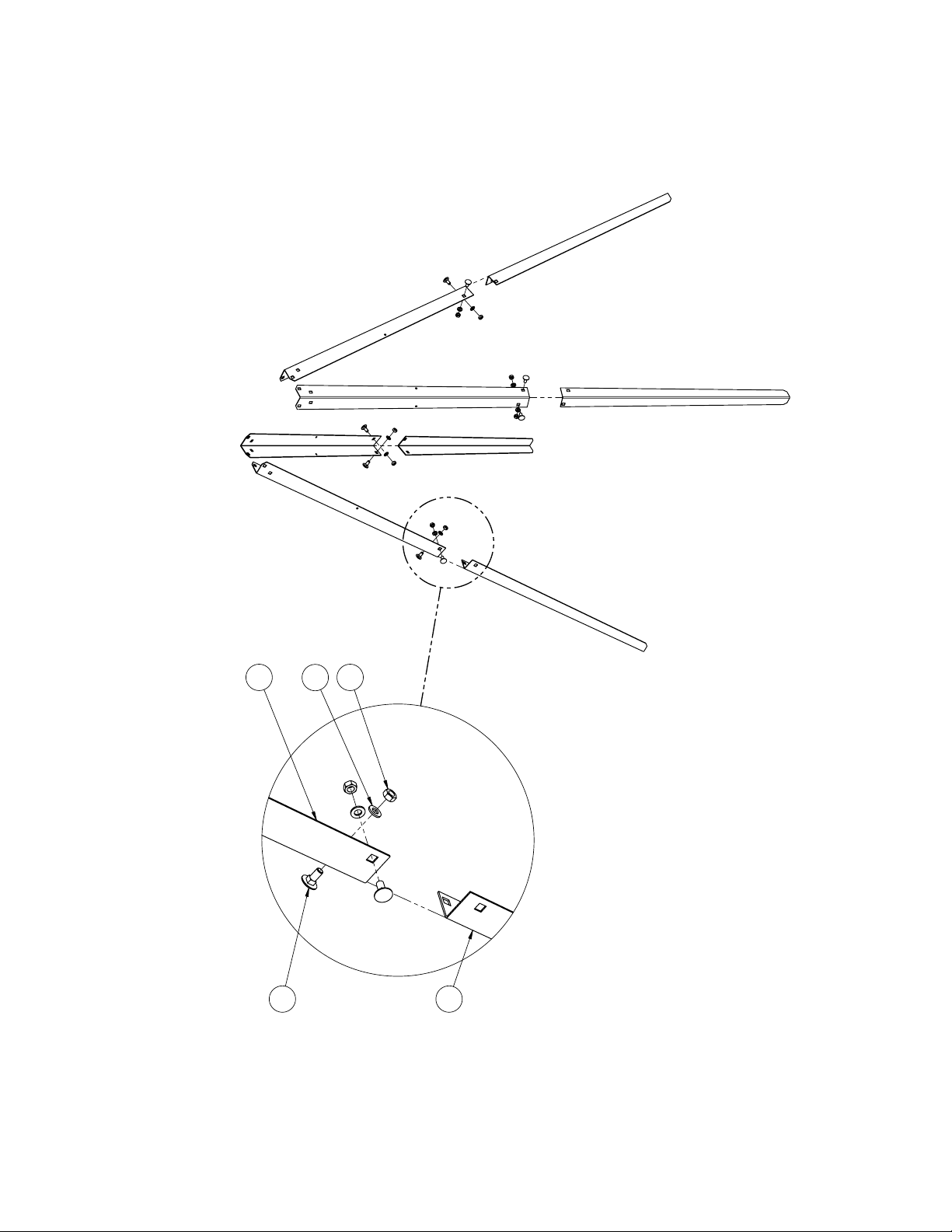

1 4 0001557

LEG PIECE A

2 4 0001558

LEG PIECE B

3 1 0001554

MOUNTING FLANGE

4 2 0001555

BLADE SUPPORT A

5 2 0001556

BLADE SUPPORT B

6 1 0001583

CONTROL BOX ASSEMBLY

7 2 0001559

BLADE GUIDE PLATE

8 1 0001600

GRINDING HEAD ASSEMBLY

9 1 0001567

MOUNTING ARM

10 1 0001553

GRINDING DISC, 6in OD, 1/4in THICK

11 1 0001570

GRINDING DISC NUT

12 1 0001579

M6 X 1.0 THREADED STUD

13 1 0001562

GRIND SHIELD

14 1 0001601

FEED LINK ASSEMBLY

15 1 0001751

KNOB, MULTI-LOBE, 50 mm OD, M10 X 1.5, 40 mm LG

16 2

6000-2RS

BALL BEARING, DOUBLE SEALED, 6000-2RS, 10 mm BORE, 26 mm OD, 8 mm WIDE

17 1

HDW

LOCK NUT, M10 X 1.5

18 3

HDW

FLAT WASHER, M10

19 2

HDW

FENDER WASHER, M10, 28 mm OD

20 1

HDW

HEX BOLT, M10 X 1.5, 65 mm LG, 26 mm LG THD

21 20

HDW

HEX NUT, M5 X 0.8

22 2

HDW

PRESSED WING NUT, M5 X 0.8

23 22

HDW

FLAT WASHER, M5

24 22

HDW

CARRIAGE BOLT, SQ NECK, M5 X 0.8, 12 mm LG

25 1

HDW

ACORN NUT, M6 X 1

26 1

HDW

HEX NUT, M6 X 1

27 1

HDW

KNOB, MULTI-LOBE, 32mm OD, M6 X 1.0, 12mm DEEP

28 1

HDW

KNOB, CIRCULAR KNOBBED, M6 X 1.0, THROUGH HOLE

29 2

HDW

HEX BOLT, M6 X 1, 15 mm LG

30 1

HDW

KNOB, 4 LOBE, 32mm OD, M6 X 1.0, 16.5mm LG

31 1

HDW

SCREW, TRH, No.8 X 3/8in LG